Rubber composition containing carbon nano-tube

A technology of carbon nanotubes and compositions, which is applied in the field of curable compositions, and can solve problems such as unpredictability and existing space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

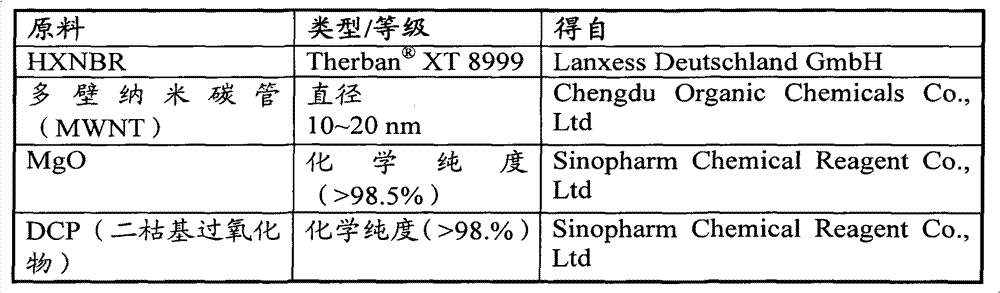

[0089] The details of the raw materials used in the following examples are summarized in Table 1 below.

[0090]

[0091] Preparation of curable composition according to the present invention

[0092] Use an internal mixer to mix HXNBR and MWNT in a ratio of 9:1 by weight. A two-roll rubber mixer was used to dilute the masterbatch containing 10wt% MWNT into different concentrations of MWNT. The final concentration of MWNT in HXNBR is 0 parts, 1 part, 2 parts, and 4 parts per hundred parts (phr) of HXNBR (see Table 2). After 5 minutes of HXNBR / MWNT plasticization, the curing agent DCP was added. Finally, the HXNBR mixture was cured at 10°C for 20 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com