Waxiness candler and preparation method thereof

A technology of candlesticks and wax, which is applied in the field of candlesticks made of wax and its preparation, can solve the problems of waste, lack of aesthetic feeling, inability to play decoration and lighting, etc., and achieve the effect of wide application and strong sturdiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

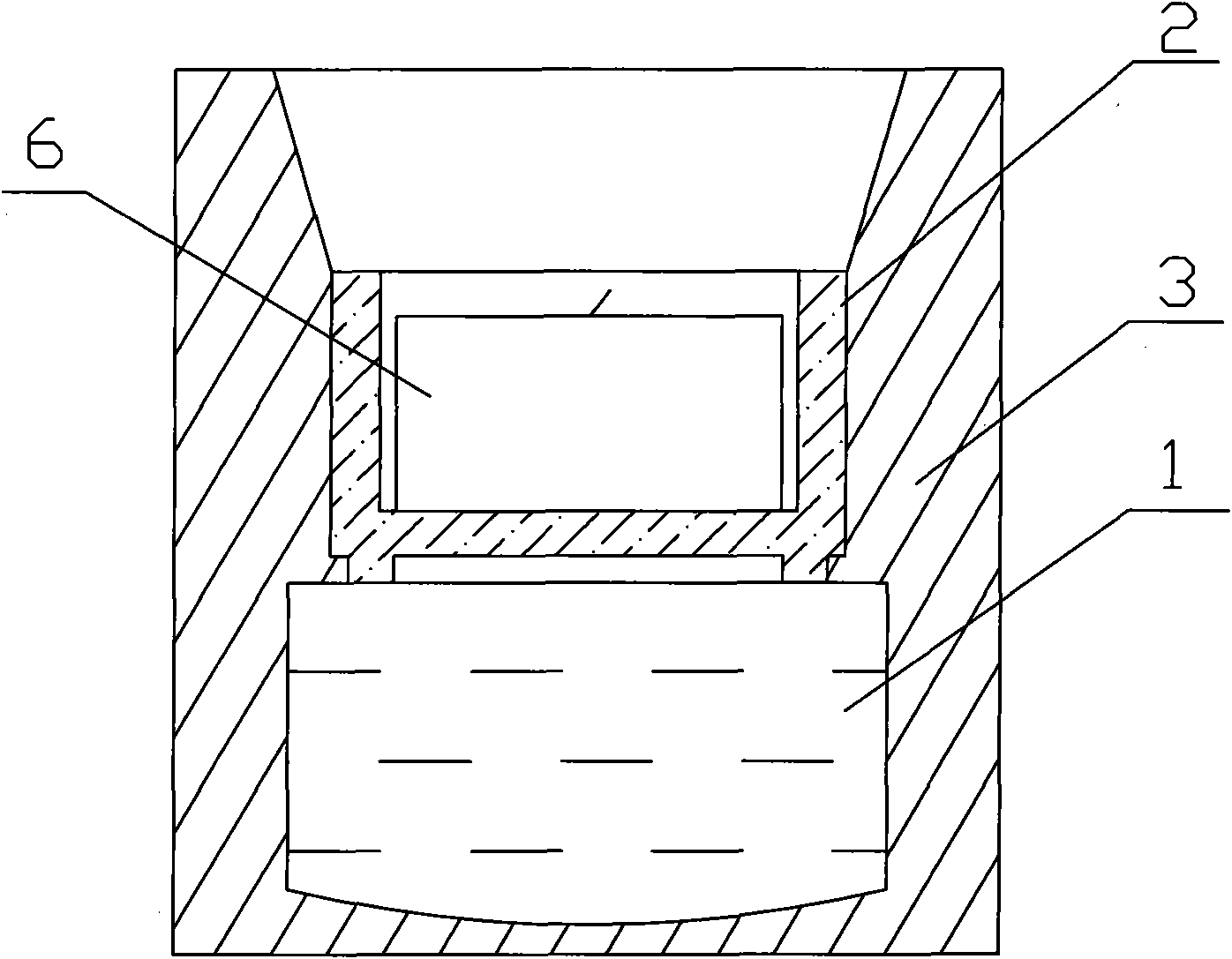

[0033] Preparing the Wax Candlesticks

[0034] 1) Put the glass cup 2 upside down into the mould, and position it by the slot at the bottom of the mould;

[0035] 2) Put the inner wax block 1 on the inverted glass cup 2, the inner wax block 1 has a positioning point combined with the cup, and the diameter is 5mm;

[0036] 3) Pour the shell layer 3 formula wax liquid into the mold, the pouring temperature is 75-80 degrees, and the surface is repaired once. The mass percent of the wax liquid mixture in the shell layer is: 6% of low-density polyethylene resin, 0.02% of color stabilizer CS35000, and the balance is fully refined wax;

[0037] 4) demoulding after cooling and solidification to obtain a waxy candlestick.

[0038] Wax candlestick, the inner wax block 1 is located at the bottom side inside the wax candlestick; the glass cup 2 is located above the inner wax block 1 inside the wax candlestick, and is closely connected with the inner wax block 1; the outer shell layer 3 ...

no. 2 approach

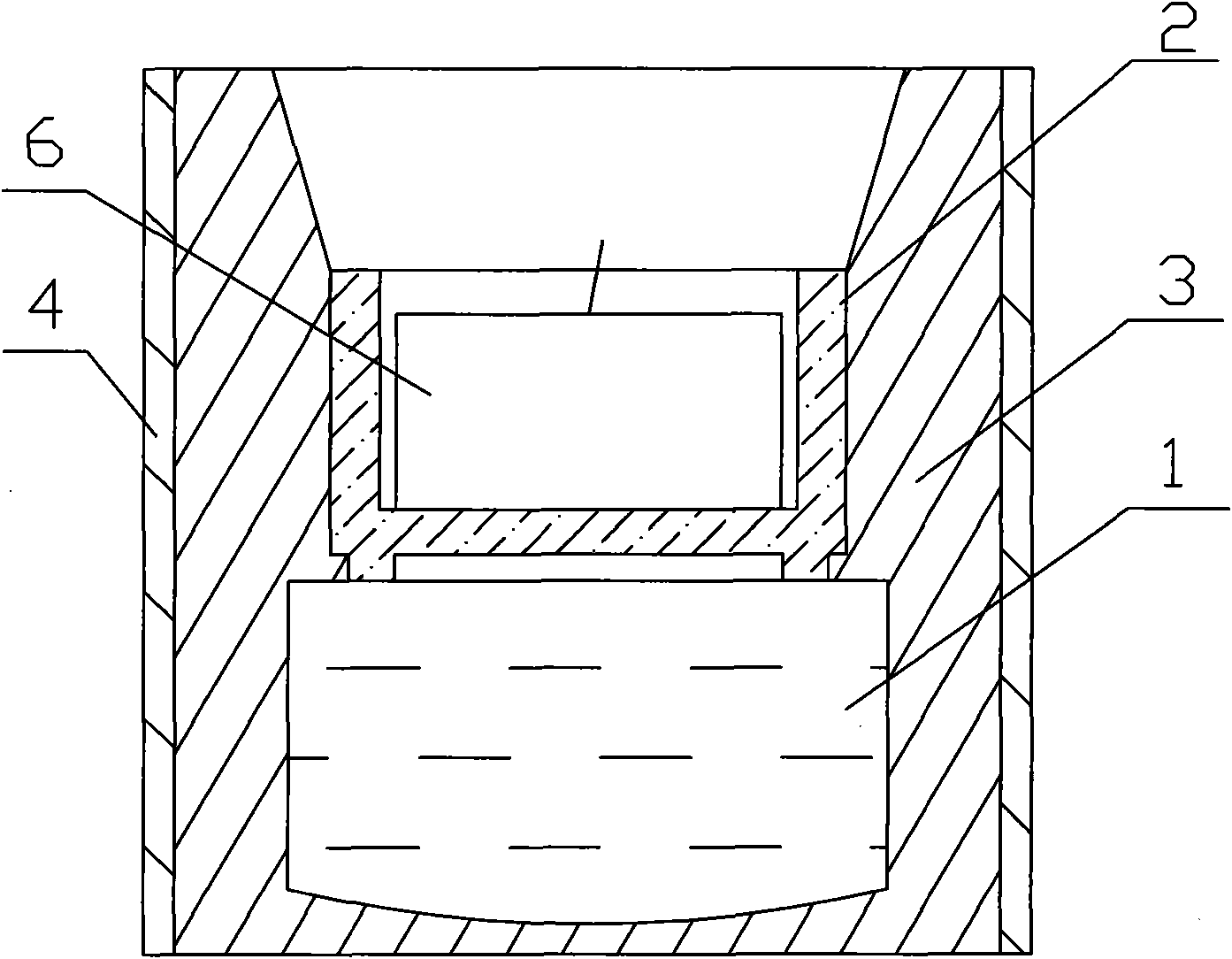

[0040] Waxy candlestick, the mass percent of wax liquid mixture of shell layer is: low-density polyethylene resin 10%, color stabilizer CS3500 1%, the balance is the whole refining wax; Its manufacturing steps and structure are the same as embodiment 1, will make The outside of the shell layer 3 of the wax candle holder is screen printed to obtain a wax candle holder with a decorative layer 4 . Place a large tealight 6 in the glass 2.

no. 3 approach

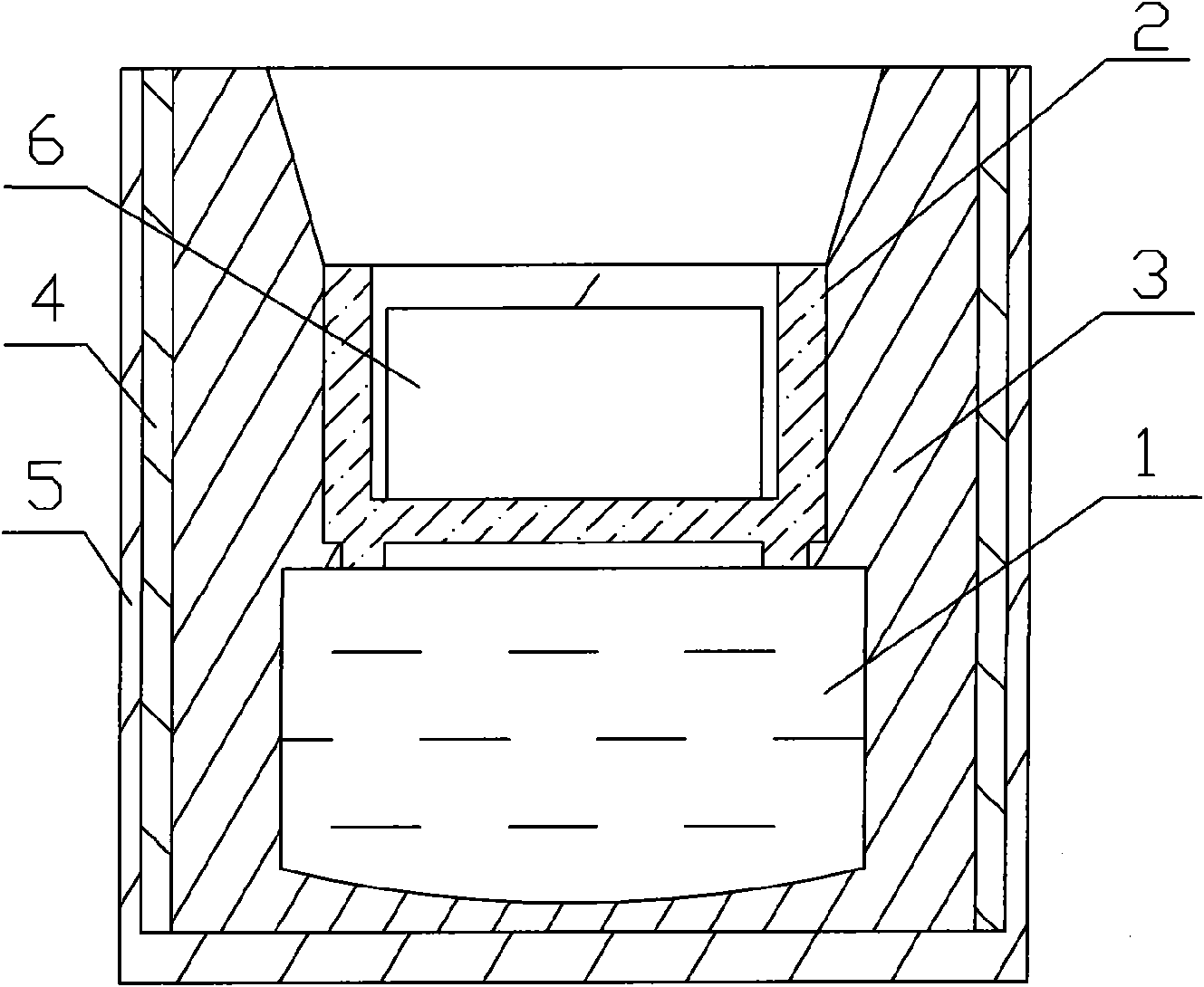

[0042] Waxy candlestick, the mass percent of the wax liquid mixture of shell layer is: low-density polyethylene resin 3%, color stabilizer CS3500 2%, the balance is full refining wax; Its manufacturing steps and structure are the same as embodiment 1, will make The outside of the shell layer 3 of the wax candlestick is pasted with dried flowers, that is, the decorative layer 4 is processed, the wax candlestick with the processed decorative layer is buckled upside down in the mold, poured into the wax liquid, and demoulded after cooling to obtain the waxy candlestick with the wax layer 5 candlestick.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com