Spiral-flow type biomass semi-gasifier

A biomass and semi-gasification technology, which is applied in household stoves/stoves, manufacturing combustible gas, lighting and heating equipment, etc., can solve the problems of insufficient stirring of combustible gas, high processing precision requirements, and increased processing costs, reaching the scope of use Wide, high utilization rate of heat energy, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

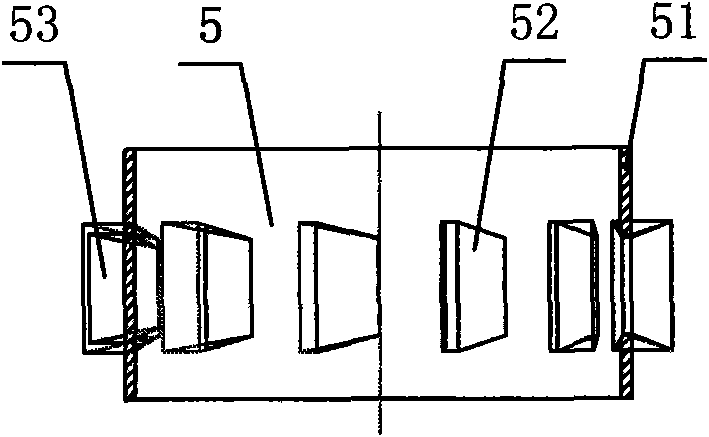

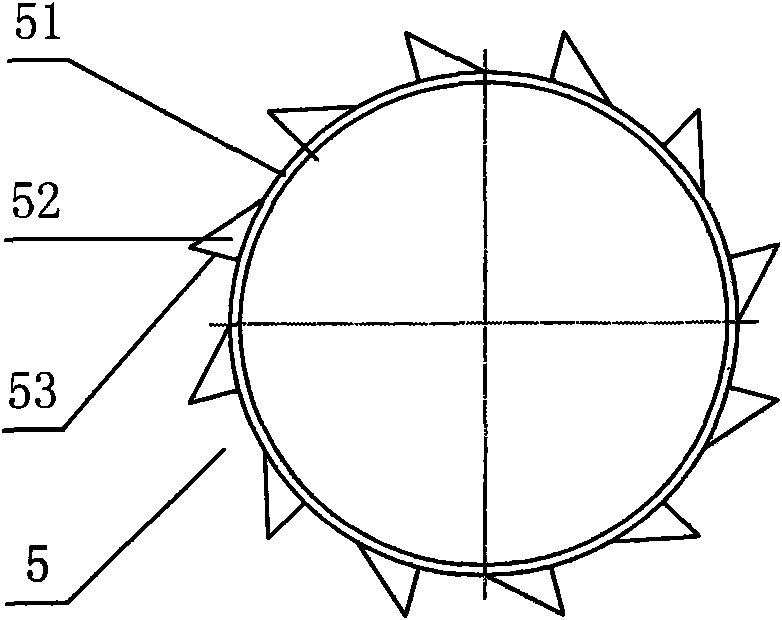

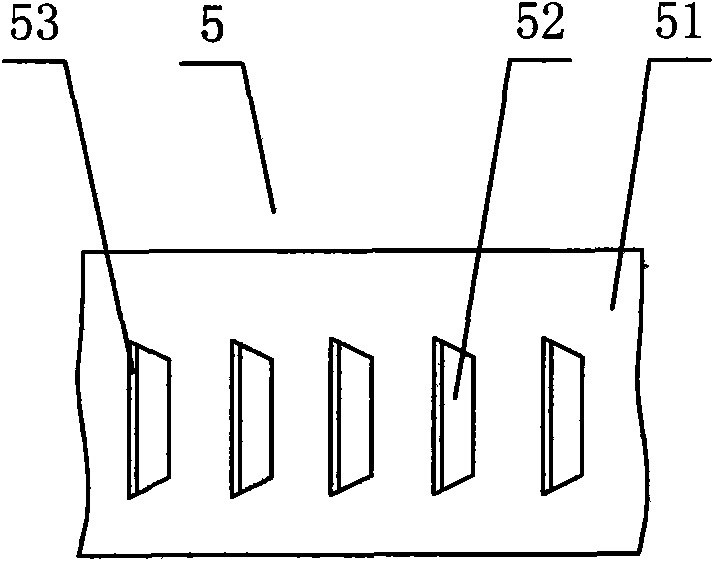

[0023] Referring to the accompanying drawings, a swirl type biomass semi-gasification furnace, which includes a furnace body composed of a bottomed inner cylinder 1 and a bottomless outer cylinder 2, a lifting furnace bridge 4 is arranged in the furnace body furnace, and a lifting furnace bridge 4 The screw rod is set as a left and right spiral thread, and the bottom of the furnace body is provided with a primary air intake channel 3. This primary air intake channel 3 passes through the bottomless outer cylinder 2 and is installed on the inner cylinder wall at the bottom of the bottomed inner cylinder 1. The upper part of the furnace body is provided with The secondary air inlet channel 5, the top of the furnace body is provided with a double-layer fire retaining ring 6 and a chimney 7 connected to the fire retaining ring channel, and the fire retaining ring channel includes an inner fire retaining ring channel 8, an outer fire retaining ring channel 9, and an inner fire retaini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com