Heat pump air-conditioning system and heat recovery system

A technology of heat pump air conditioning and heat recovery, which is applied in heat recovery systems, fluid heaters, refrigeration and liquefaction, and can solve problems such as limiting the scope of use of water-cooled heat pumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

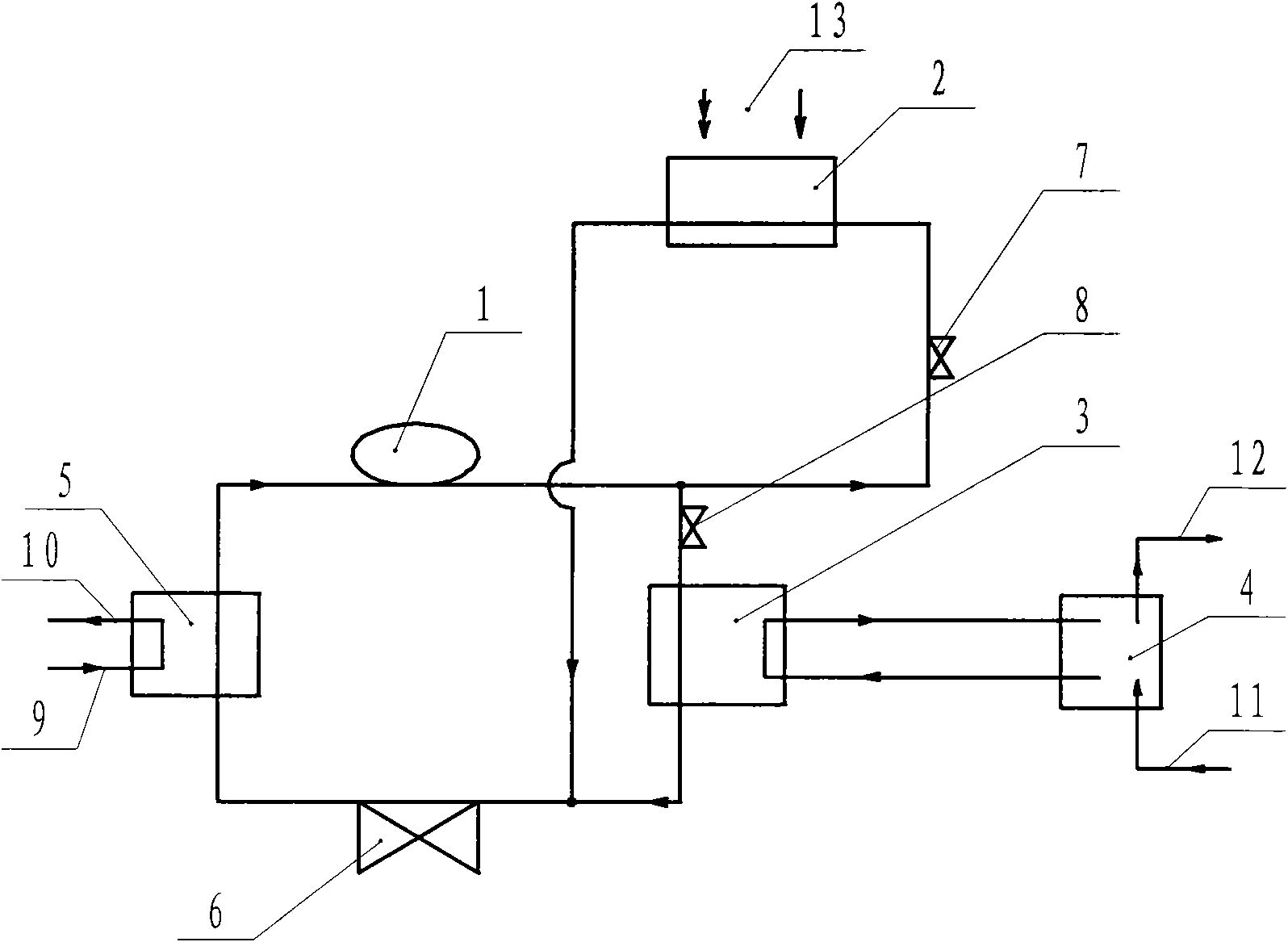

Embodiment 1

[0027] A heat pump air conditioning system and heat recovery system, including a compressor 1, an evaporator 5, a condenser 2, and an expansion valve 6; the heat release end of the heat pump is composed of two condensers, one of which is an air heat exchanger 2, Its second is water heat exchanger 3, and described water heat exchanger 3 is connected with water tank 4 (or water source) by pipeline, and water tank 4 is provided with water inlet 11 and water outlet 12; Air heat exchanger 2 and water heat exchanger 3 is connected in parallel with the pipeline to form a circuit with the compressor 1, the evaporator 5, and the expansion valve 6. The pipeline is equipped with a control valve 7 and a control valve 8; the water tank 4 is heat-preserved; Heater, air heat exchanger 2 adopts metal fin fan coil structure, and is designed according to the design standard of ultra-low temperature air source heat pump.

[0028] Summer work process:

[0029] The unit automatically enters the h...

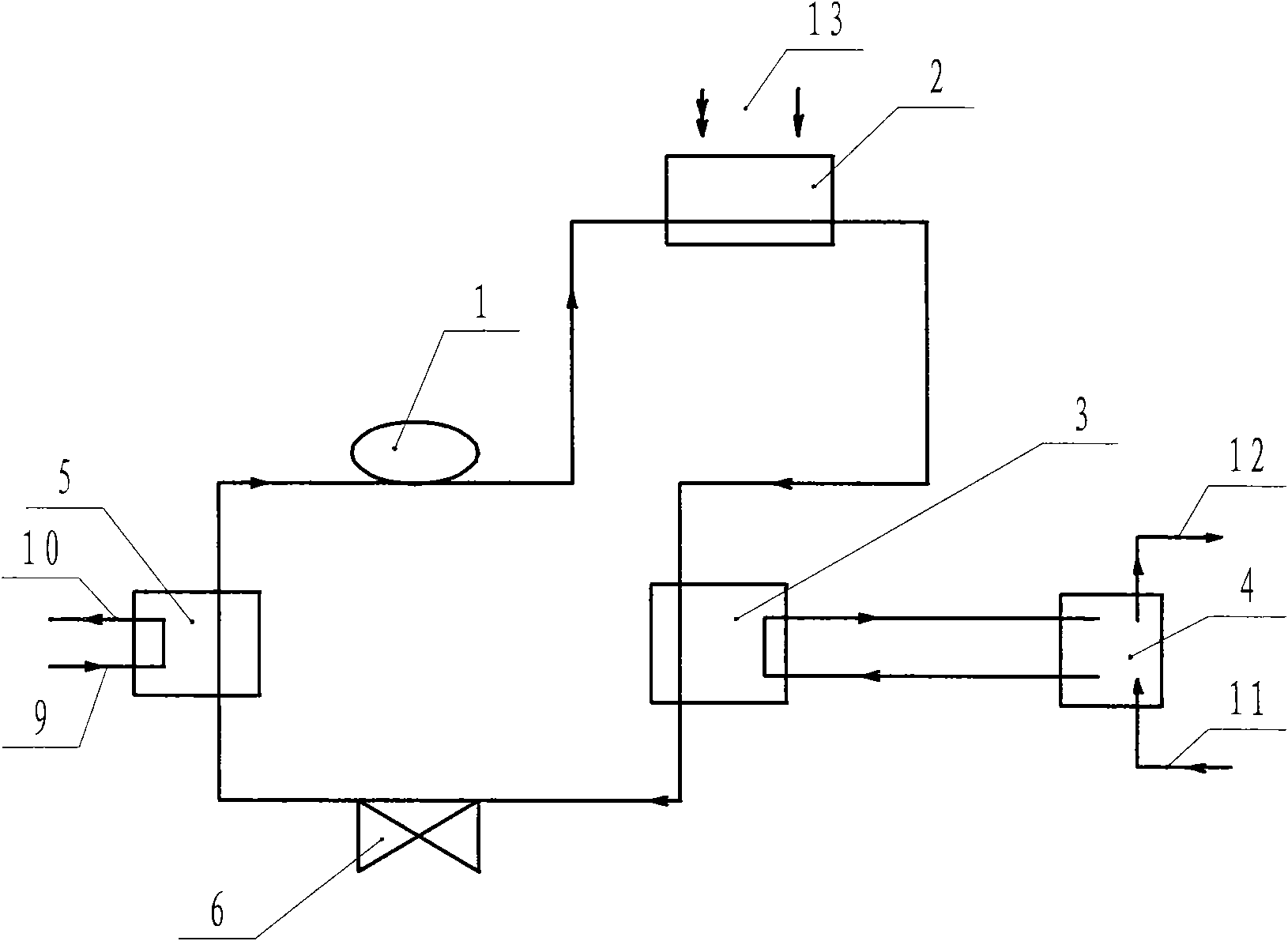

Embodiment 2

[0033] The air heat exchanger 2 and the water heat exchanger 3 are connected in series without using the control valve 7 and the control valve 8 . When working in summer, the air heat exchanger 2 and water heat exchanger 3 exchange the heat released by the system to the air and water in the water tank respectively; when working in winter, the air heat exchanger 2 and water heat exchanger 3 can work simultaneously , can also use one of them to work.

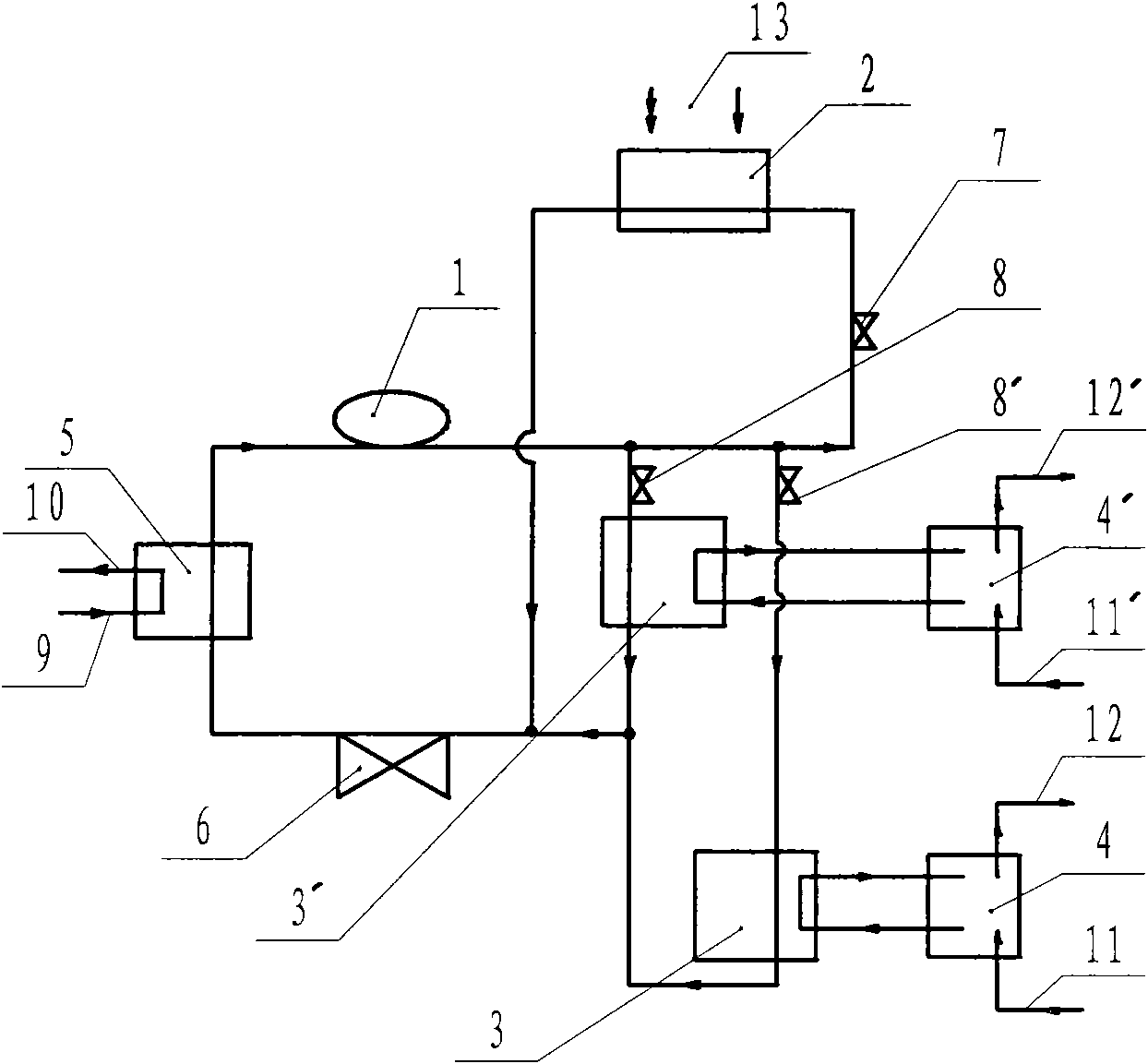

Embodiment 3

[0035] The water heat exchanger 3 and the water heat exchanger 3' are connected in parallel and then connected in parallel with an air heat exchanger 2. The water heat exchanger 3 and the water heat exchanger 3' are respectively controlled by the control valve 8 and the control valve 8'. This system is suitable for two situations that have different requirements for hot water temperature in summer, such as bathrooms and swimming pools.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com