Stopper structure, and its manufacturing method

A manufacturing method and stopper technology, which are used in manufacturing tools, casting equipment, casting melt containers, etc., can solve the problems of gas leakage, unstable shaft and rod fixing, and inability to ensure gas tightness, so as to improve the joining accuracy, The effect of improving operation efficiency and preventing gas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

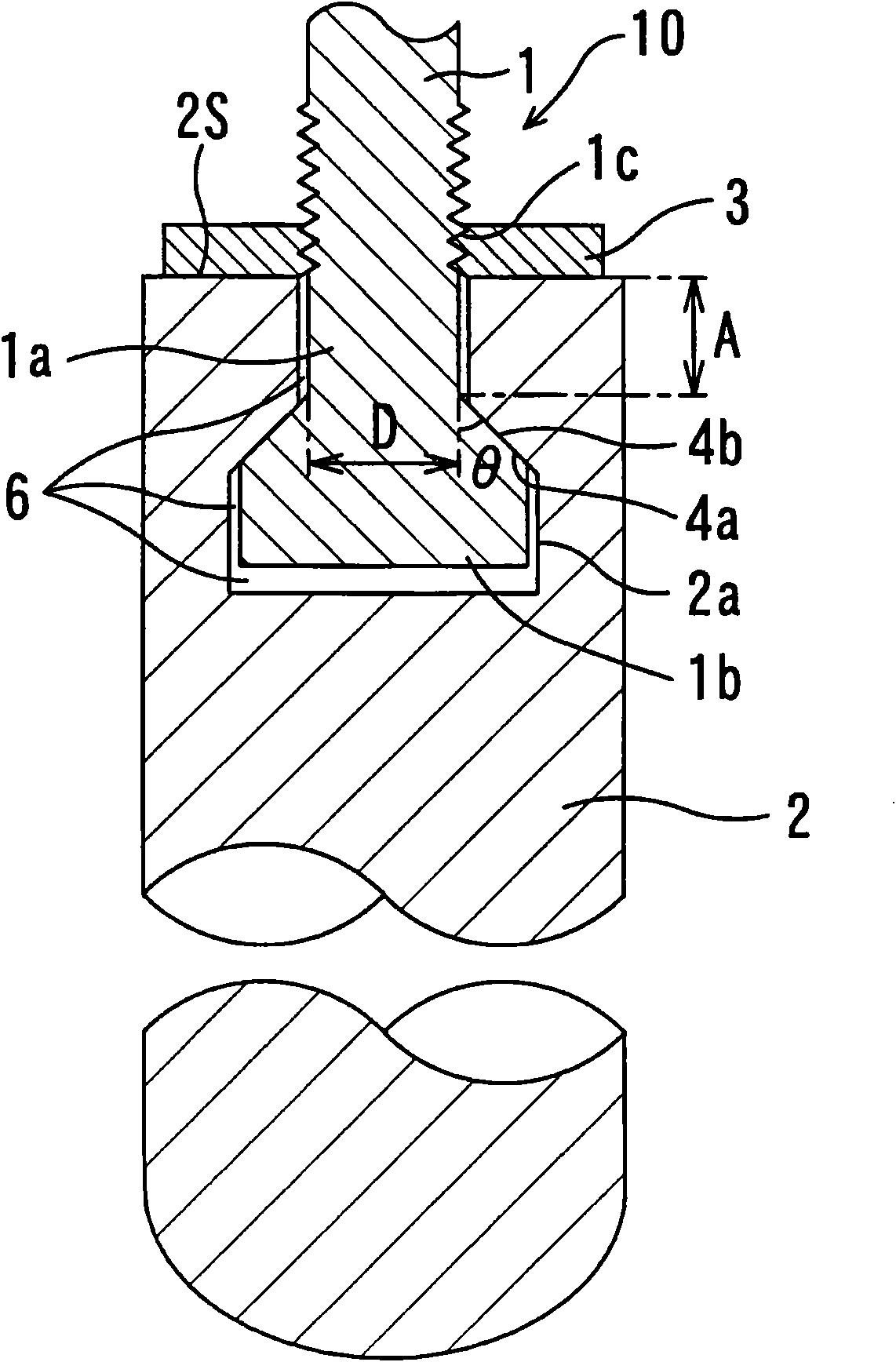

[0058] figure 1 It is a cross-sectional view showing an example of the stopper structure of the present invention.

[0059] exist figure 1 In the shown stopper structure 10 , the tip end of the metal shaft 1 is attached to the installation hole 2 a of the stopper refractory 2 via the space 6 as the expansion absorption margin of the tip end of the shaft 1 .

[0060] The distal end portion of the shaft rod 1 has a stepped structure having a small-diameter portion 1a on the base end side and a large-diameter portion 1b larger than the small-diameter portion on the distal end side, and a first tapered surface is formed between the small-diameter portion 1a and the large-diameter portion 1b. 4a. On the other hand, the mounting hole 2a of the stopper refractory 2 has a shape similar to the tip portion of the shaft rod 1, and has a second tapered surface 4b superimposed on the first tapered surface 4a on its inner surface.

[0061]In addition, the shaft rod 1 is provided with a...

Embodiment 2

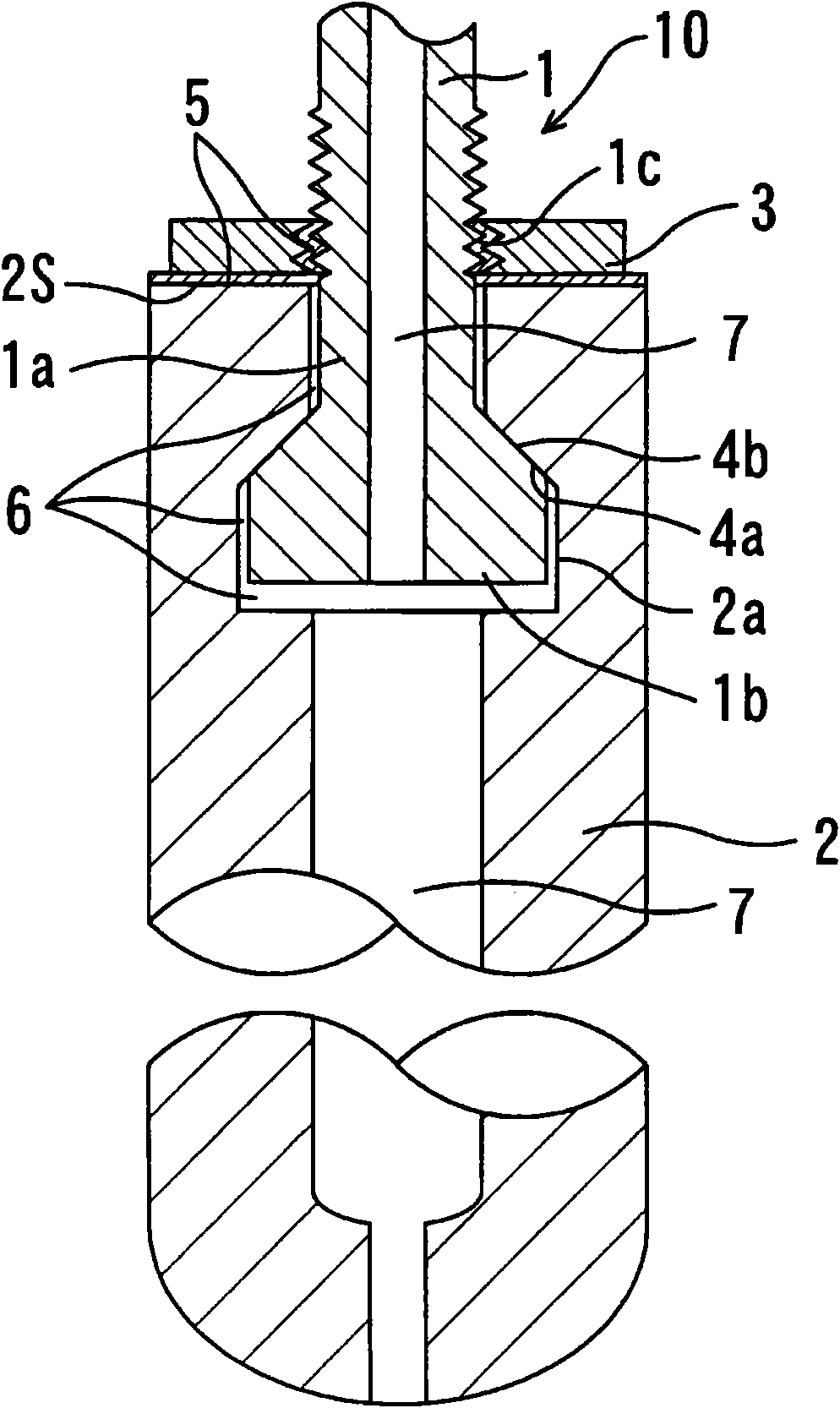

[0066] figure 2 is a sectional view showing another example of the stopper structure of the present invention. In this embodiment, the gas flow path 7 is provided inside the stopper structure 10 . In addition, coordination of the shaft rod 1 and the stopper refractory 2, connection structure, etc. are the same as those of the first embodiment.

[0067] In this embodiment, the gas flow path 7 for conducting gas to the installation hole 2 a of the stopper refractory 2 is provided inside the shaft rod 1 , and the secondary installation hole 2 a is provided inside the stopper refractory 2 . The gas flow path 7 penetrating to the top end is either blown into the molten metal from the top end of the stopper refractory, or the gas is passed through the gas flow path 7 for air-cooling the shaft rod 1 .

[0068] In this way, in this embodiment, the gas flow path 7 for conducting gas is provided inside the shaft rod 1 and the stopper refractory 2, so in order to improve the gas tight...

Embodiment 3

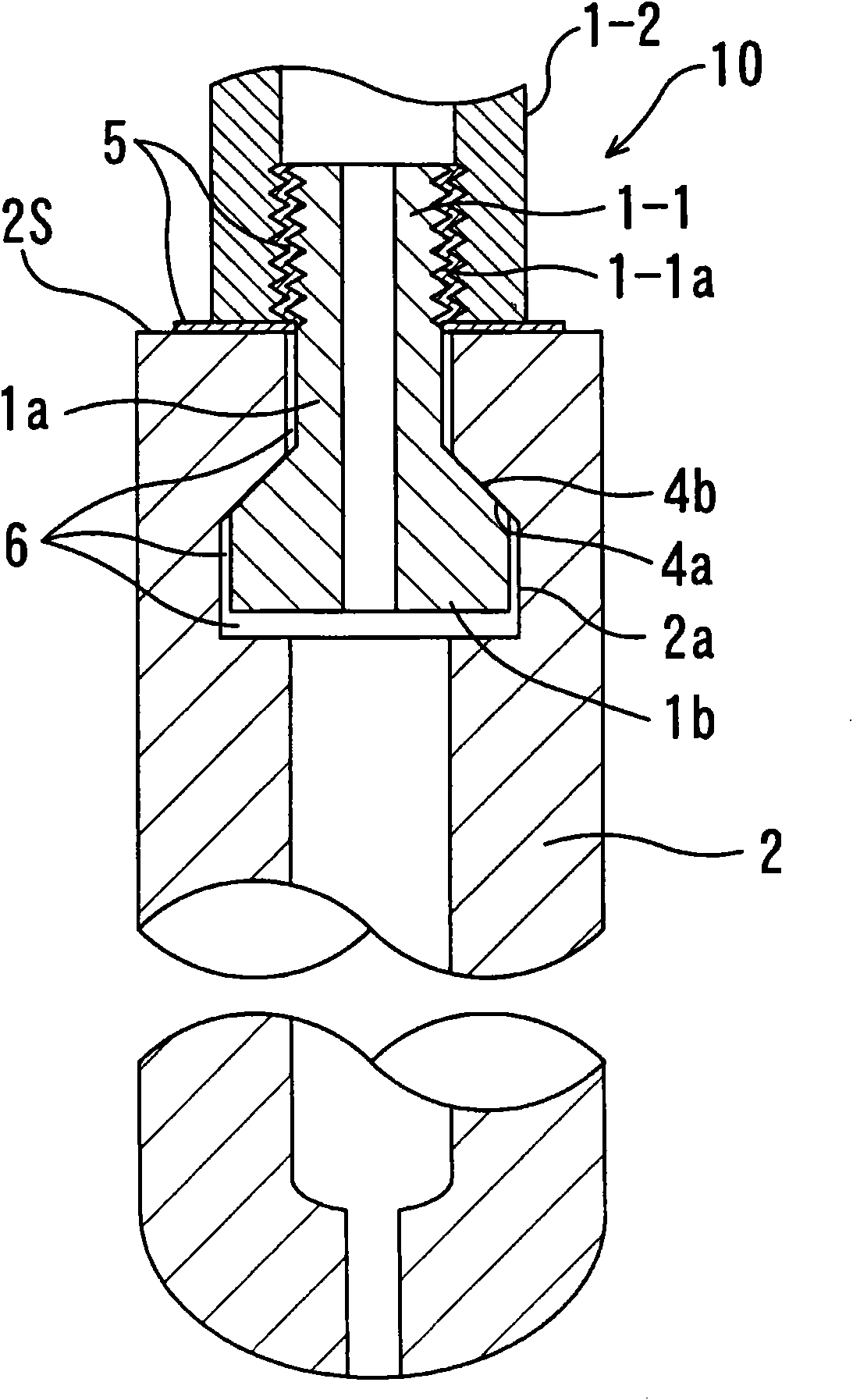

[0074] image 3 It is a sectional view showing still another example of the stopper structure of the present invention. This embodiment is an example in which the shaft 1 is divided into a first shaft portion 1-1 and a second shaft portion 1-2.

[0075] The first shaft part 1-1 is installed in the mounting hole 2a of the stopper refractory 2 at the top end thereof, on the outside above the upper end surface 2S of the stopper refractory of the first shaft part 1-1. A threaded portion 1-1a is formed. Then, the second shaft rod part 1-2 is screwed onto the threaded part 1-1a, and the lower end face of the second shaft rod part 1-2 is aligned with the upper end surface 2S of the stopper refractory by screwing it in. The upper end surface 2S of the stopper refractory is in contact, and the first shaft rod part 1-1 rises, and the surfaces of the first tapered surface 4a and the second tapered surface 4b overlap and stick together, so that the first shaft rod part 1-1 and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com