Special build-up welding machine applied to heavy binding roller or squeeze roller

A technology of squeezing rollers and rolling rollers, which is applied in the field of welding equipment, can solve the problems of unreasonable design of active alignment and clamping workpiece equipment, inability to meet the volume of large workpieces, unfavorable replacement of welding wire reels, etc., and achieve easy replacement, reasonable structure, and work. The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

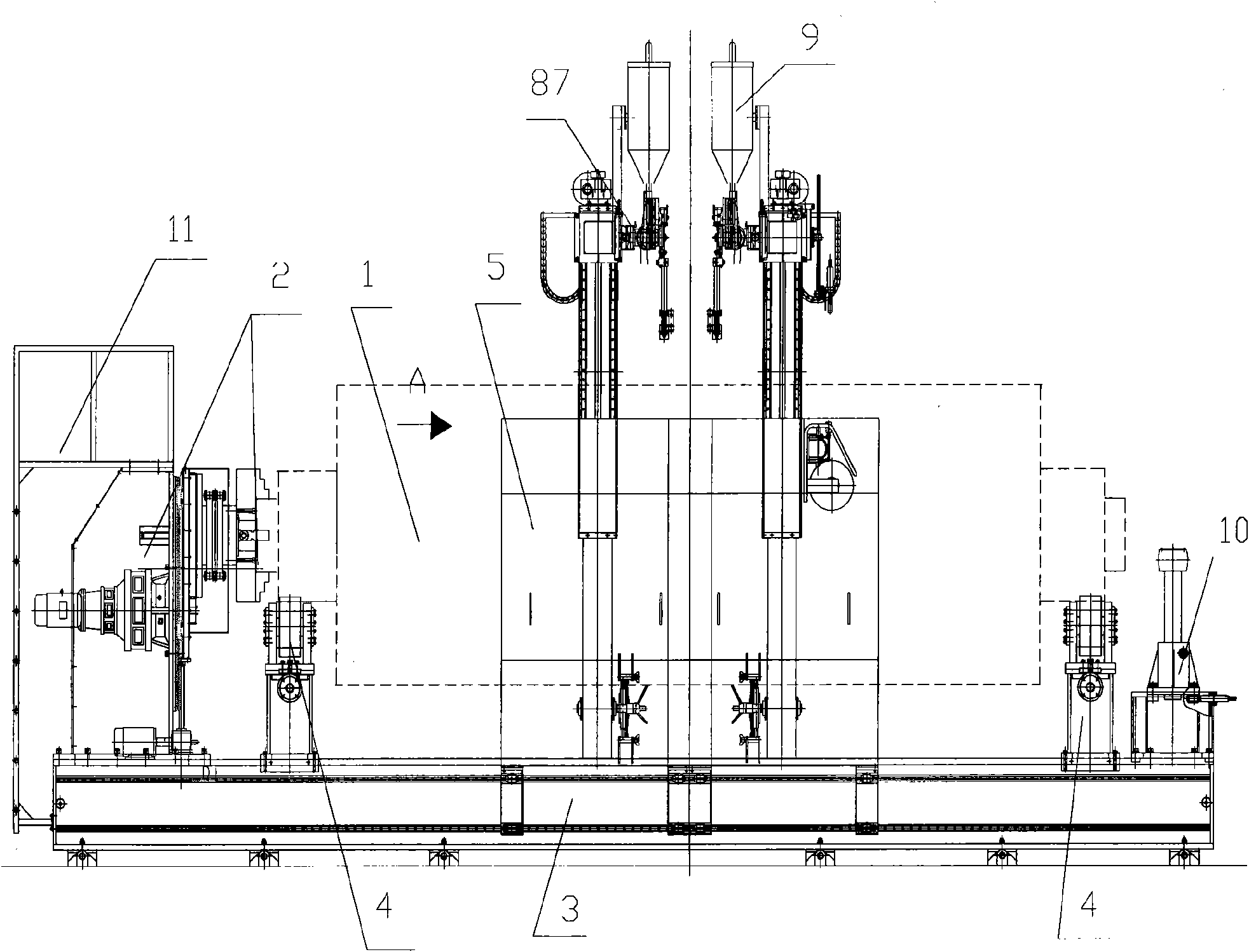

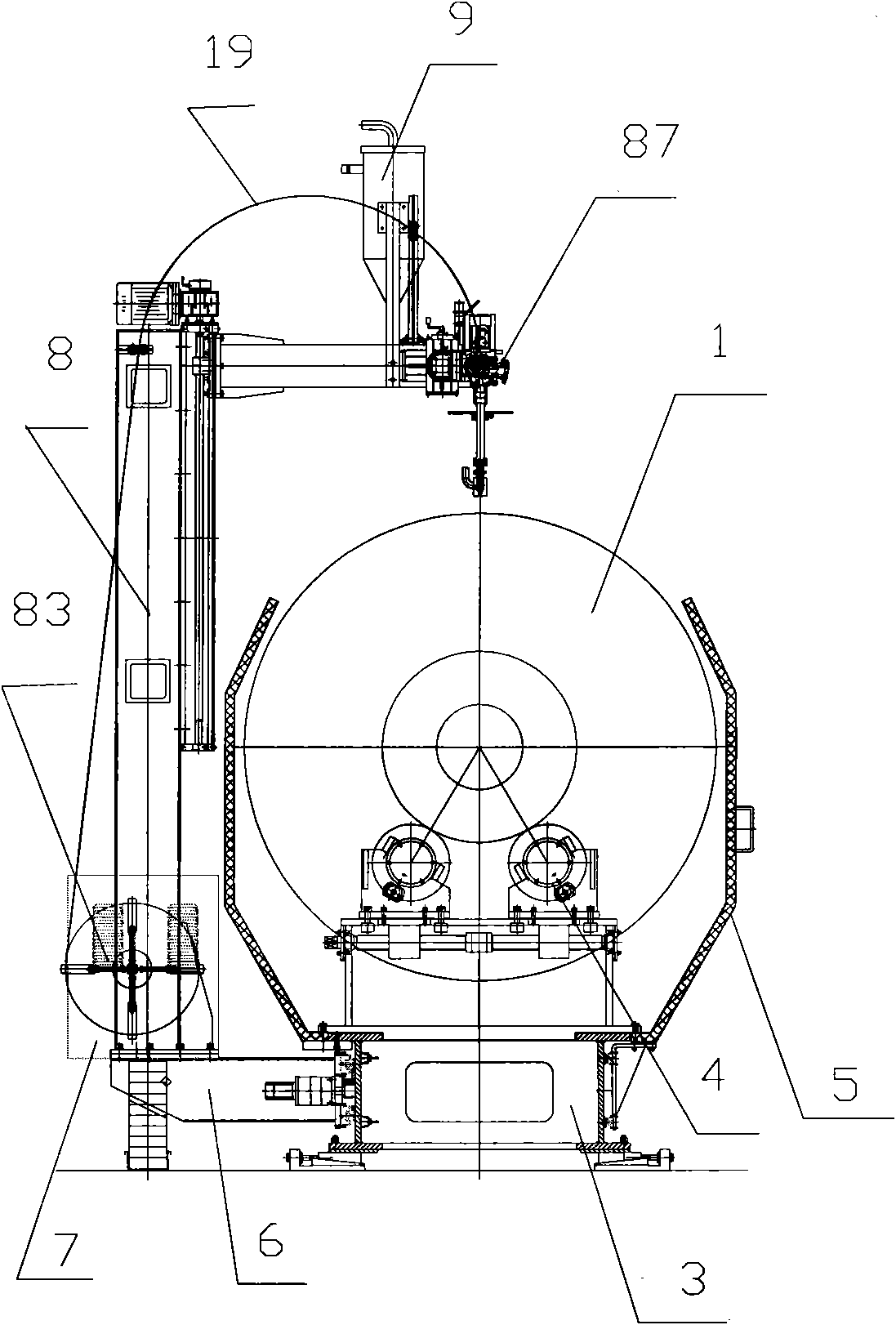

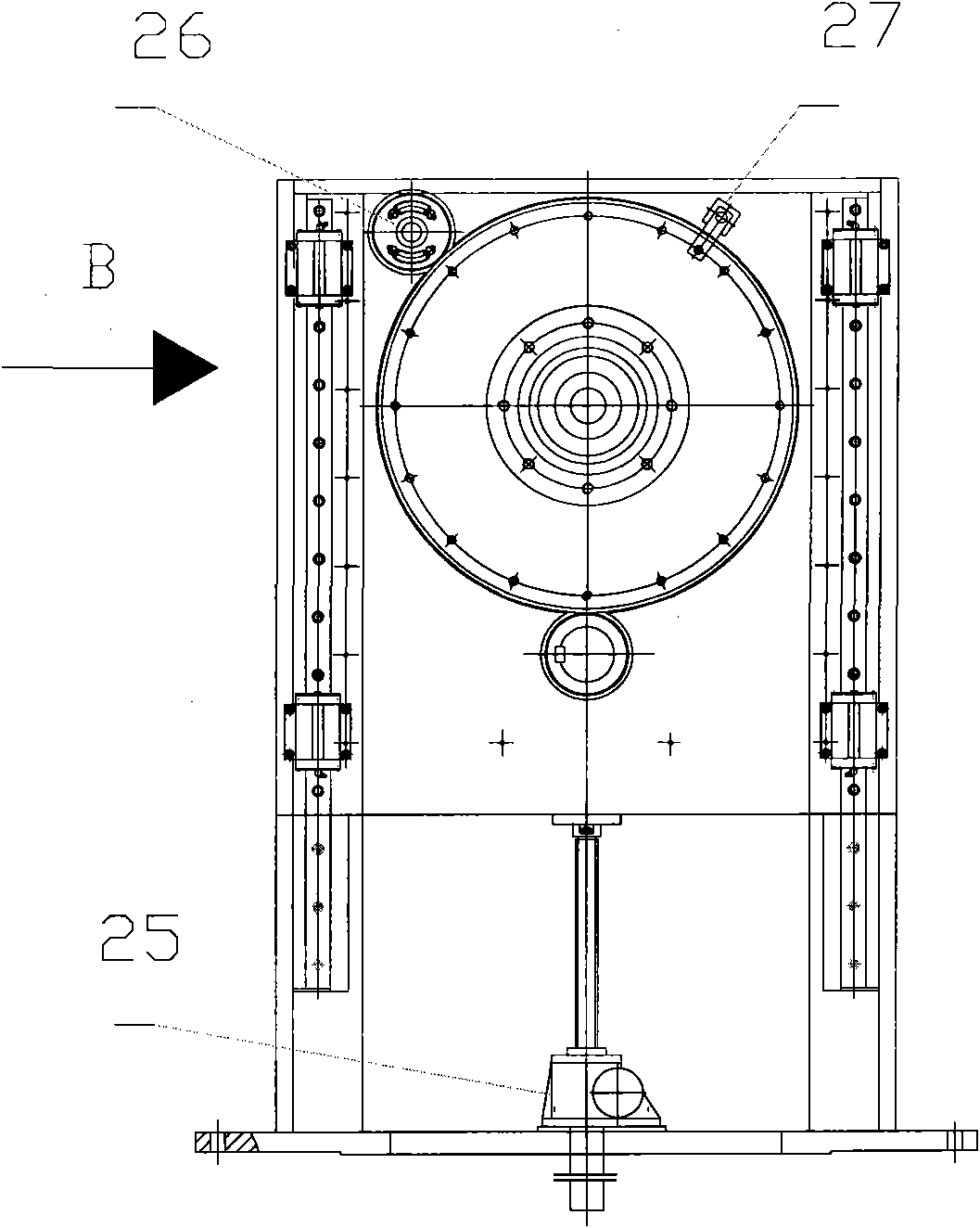

[0032] Such as figure 1 , 2, 3, 4, 7, and 8, a special machine for surfacing welding applied to heavy-duty rolls or extrusion rolls, including a machine base 3, on which are two slide rails, on which there are at least two movable Adjustable support rotating tire 4 is installed on the slide rail at a certain distance from each other, and can move on the track along the slide rail axis direction. The main shaft box 2 and the anti-channeling device 10 are respectively installed at the two ends of the support 3, and the height and the horizontal position of the anti-channeling roller of the anti-channeling device are steplessly adjustable. The spindle box 2 includes a box body 24, a floating chuck 21, a spindle transmission system 23, a pneumatic top 22, a lifting mechanism 25, a rotary speed measuring device 26 for precisely controlling the spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com