Reinforced heat transfer tube

A technology of heat transfer tubes and outer tubes, applied in the field of heat transfer tubes, can solve the problems of deformation of the helical sheet, decrease of the guiding effect of the helical sheet, blockage of the heat transfer pipe, etc., and achieve the effects of reducing the volume, improving the rigidity and increasing the specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

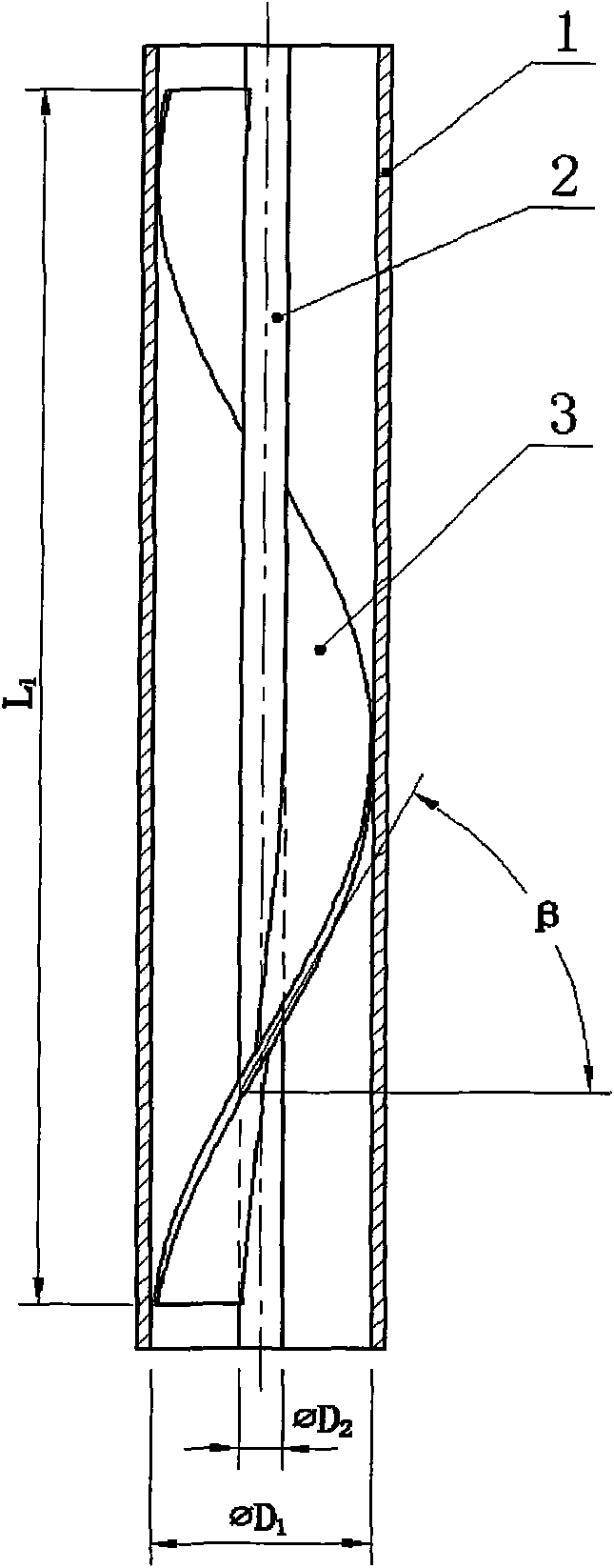

[0036] A kind of enhanced heat transfer tube, its structure is as figure 1 As shown, the technology of the present invention is used to manufacture radiant furnace tubes. The heat transfer tube is composed of an outer tube 1, a fixed rod 2 and a spiral band 3. A piece of spiral band 3 is welded by high-frequency welding technology on the fixed rod. The spiral band 3 is the right Spiral ribbon. The specific parameters of the radiant furnace tube are: the total length of the furnace tube is 12000 mm, and the inner diameter of the outer tube 1 is D 1 =100mm, the wall thickness is 6.5mm, the outer diameter D of the fixed rod 2 2 =25mm, the helix angle β=60° of the spiral band 3, the thickness of the spiral band 3 is 5mm, the length L of the spiral band 3 1 =11940mm. The circulation area of the radiation furnace tube is 7175mm 2 , the specific surface area is 43.79 (unit is 1 / m), and the inner diameter of the ordinary tube with the same flow area as this radiant furnace tube ...

Embodiment 2

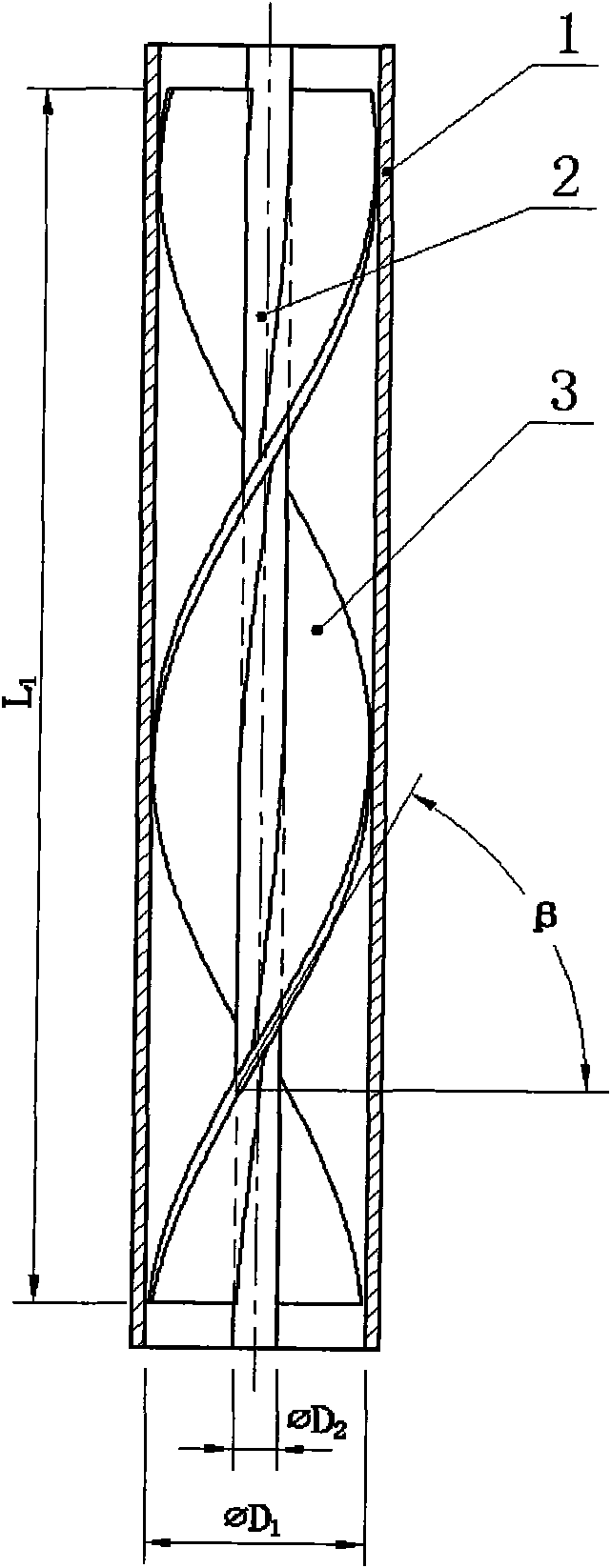

[0038] A kind of enhanced heat transfer tube, its structure is as figure 2 As shown, the heat transfer tube includes an outer tube 1, a fixed rod 2 and a spiral band 3, the outer tube 1 is a cylindrical hollow tube, the fixed rod 2 is a solid metal rod, and the spiral band 3 is continuously welded on the fixed rod 2 to form a spiral band , the fixed rod 2 and the spiral band 3 form an insert, which is placed in the outer tube 1, and the same helical segment on the fixed rod 2 is welded with two spiral bands 3 in the same spiral direction, and the spiral band 3 is made of stainless steel with the same material as the fixed rod. , the helical band 3 is a right-handed helical band, the helical angle β=45° with the horizontal direction, and the length L of the helical band 3 1 is the inner diameter of the outer tube 1 D 1 5 times of , the outer diameter D of the fixed rod 3 2 is the inner diameter of the outer tube 1 D 1 0.1 times of , the inner insert formed by the fixed rod ...

Embodiment 3

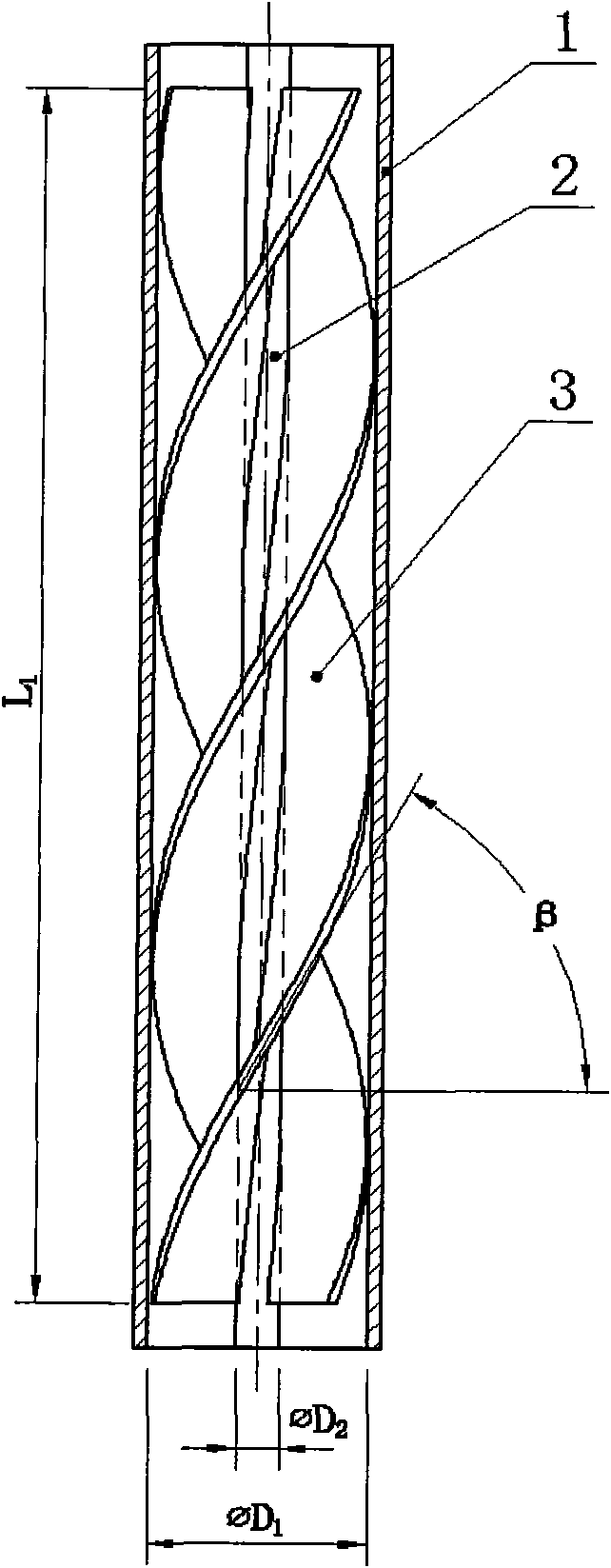

[0040] A kind of enhanced heat transfer tube, its structure is as image 3 As shown, the heat transfer tube includes an outer tube 1, a fixed rod 2 and a spiral band 3, the outer tube 1 is a cylindrical hollow tube, the fixed rod 2 is a solid metal rod, and the spiral band 3 is welded on the fixed rod 2 in sections to form a spiral section, the fixed rod 2 and the spiral band 3 form an insert, which is placed in the outer tube 1, and the same helical segment on the fixed rod 2 is welded with three spiral bands 3 in the same spiral direction, and the spiral band 3 is made of stainless steel with the same material as the fixed rod. Material, the spiral band 3 is a left-handed spiral band, the spiral angle β=85° with the horizontal direction, and the length L of the spiral band 3 1 is the inner diameter of the outer tube 1 D 1 50 times of , the number of helical segments is 4, and the pitch of helical segments is L 2 is the inner diameter of the outer tube 1 D 1 30 times of , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com