Method for detecting and evaluating sound emission of crane

An acoustic emission detection and crane technology, applied in the field of non-destructive testing, can solve problems such as inapplicability, structural type and detection signal influence, and achieve the effect of avoiding danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

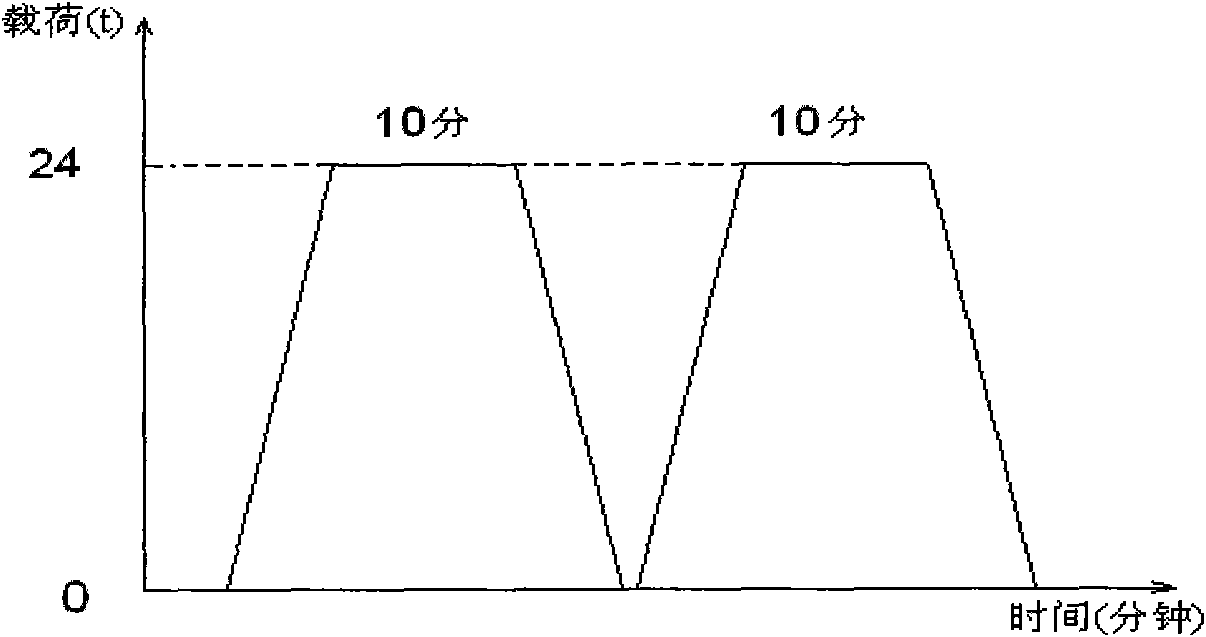

[0031] In this embodiment, a bridge crane is taken as an example, and the method for detecting and evaluating the crane through acoustic emission technology includes the division of the activity and intensity of the acoustic emission location source area, and the evaluation of the risk degree of the acoustic emission source, including the following steps:

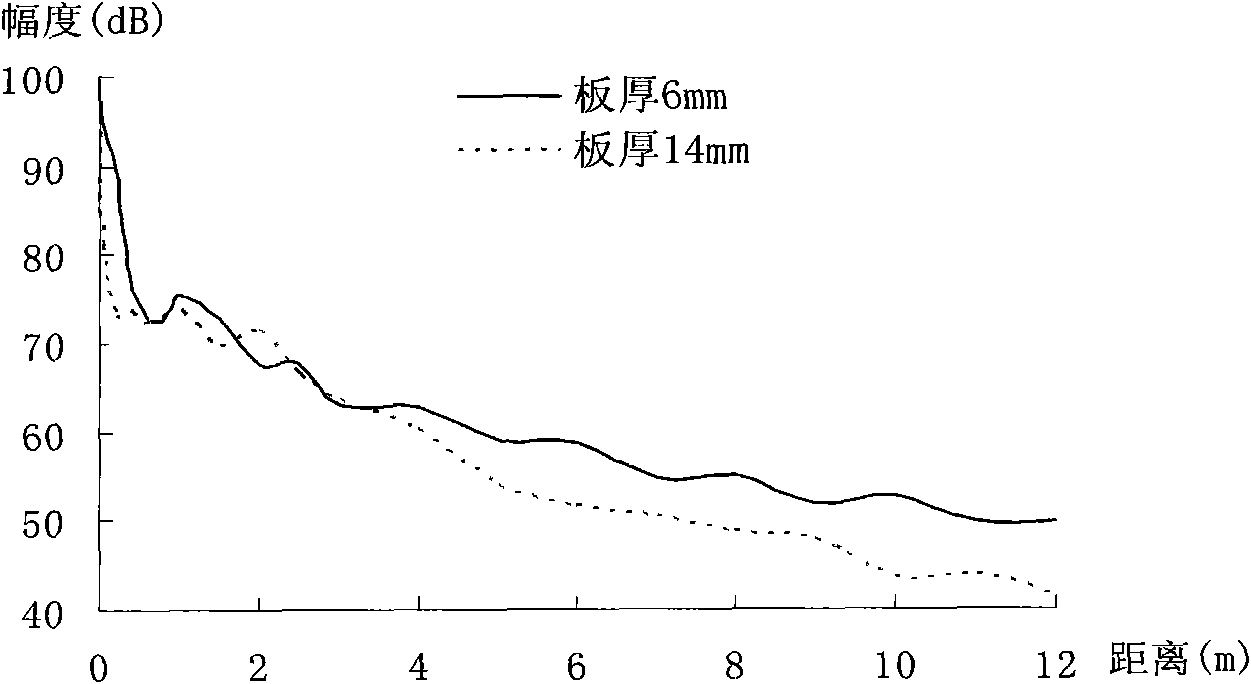

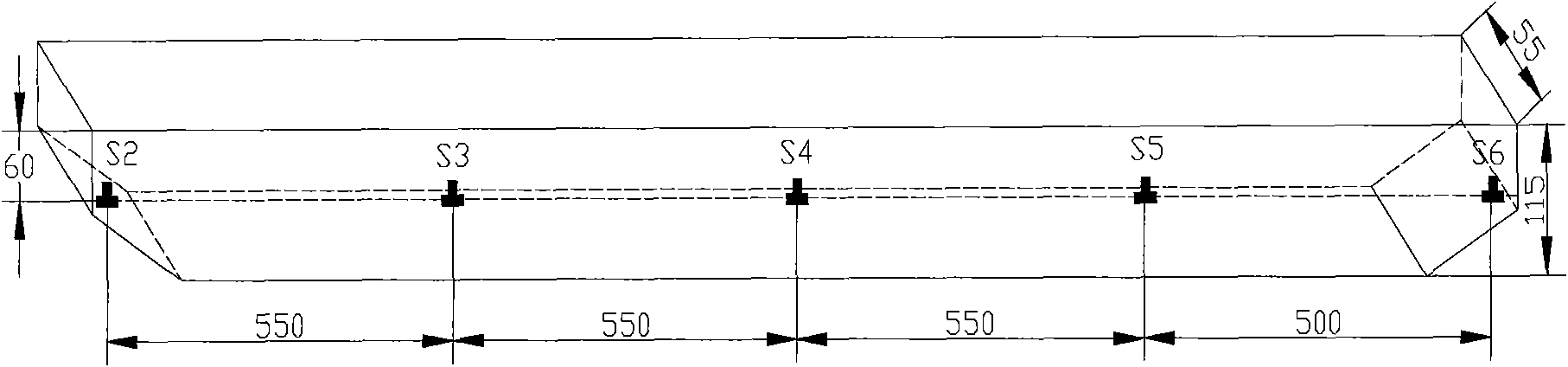

[0032] 1. According to the requirements of crane detection, the basic requirements of the acoustic emission detection system are stipulated, including the recommended resonant response frequency range of the probe (ie sensor) in the range of 100kHz to 400kHz, the basic requirements of the preamplifier and the acoustic em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com