High styrene sbs hot melt adhesive

A technology of hot melt adhesives and styrene content, applied in the direction of adhesives, etc., can solve problems such as difficult mixing, and achieve the effects of long construction time, good cohesive strength, and high bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0062] In yet another embodiment, the adhesive comprises:

[0063] (a) 10-30% by weight of a substantially linear styrene-butadiene-styrene block copolymer having a styrene content of greater than 35%, preferably from about 38% to about 50% by weight;

[0064] (b) 5-20% by weight of end-block resin;

[0065] (c) 45-65% by weight of tackifier;

[0066] (d) 0-30% by weight oil; and

[0067] (e) 0-3% by weight of antioxidant.

[0068] In a preferred embodiment, the present invention relates to a multipurpose hot melt adhesive comprising:

[0069] (a) 15-25% by weight of a substantially linear styrene-butadiene-styrene block copolymer containing 40% by weight of styrene;

[0070] (b) 5-25% by weight aromatic end-block resin;

[0071] (c) 45-65% by weight of tackifier;

[0072] (d) 5-20% by weight of oil; and

[0073] (e) 0.3-1.5% by weight antioxidant, wherein the tackifier is present in an amount greater than that of the block copolymer, and wherein the adhesive has a visc...

Embodiment 1

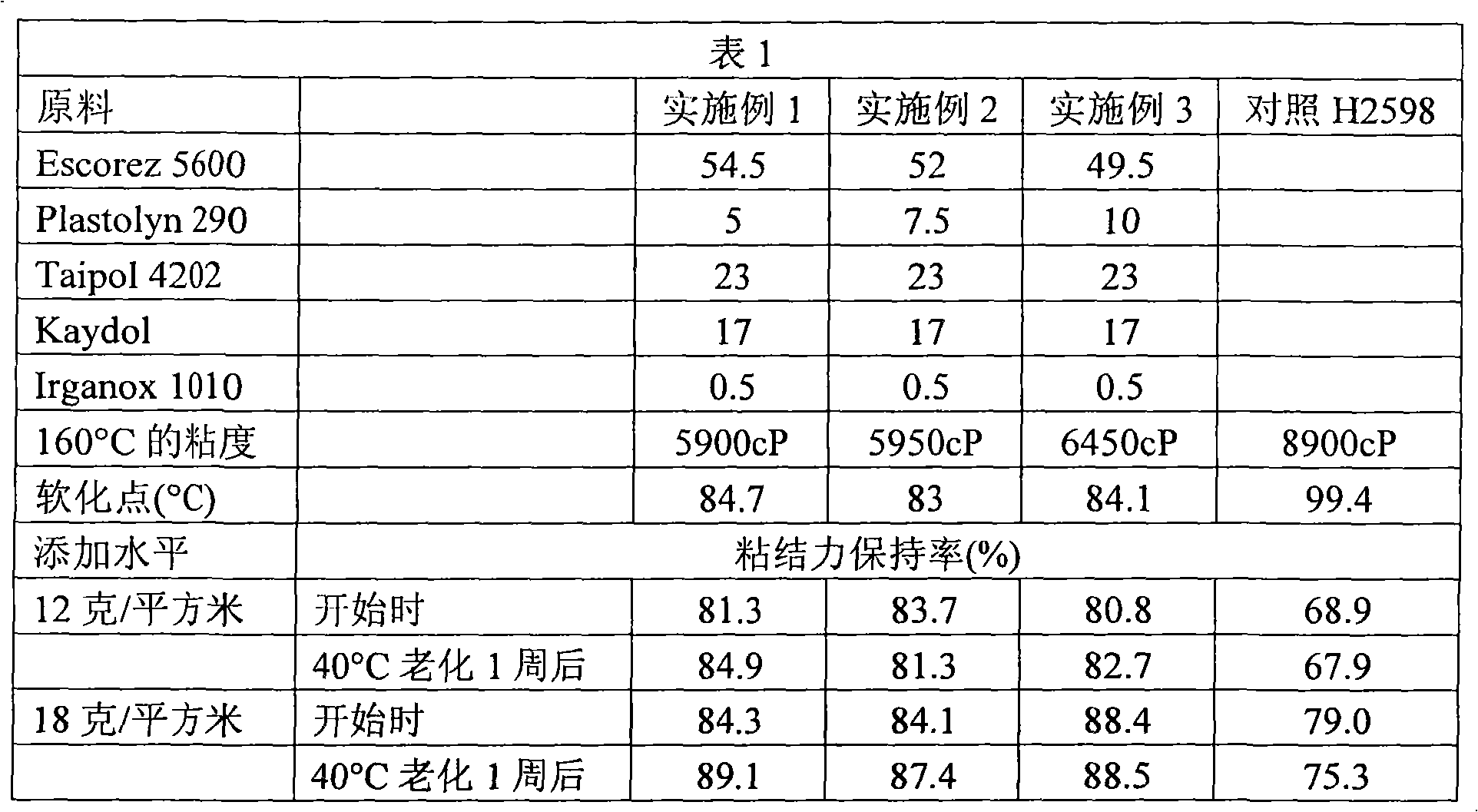

[0099] Referring to Table 1, Examples 1, 2 and 3 are formulations made according to the present invention. These three high styrene content linear SBS block copolymer based formulations were compared to a commercially available high styrene SIS based elastic attachment adhesive H2598. Table 1 illustrates that Examples 1, 2 and 3 have advantageously lower viscosities than H2598 at 160°C. The adhesives of Examples 1-3 were found to have low melt viscosity, good sprayability and excellent creep retention properties. They also have a lower softening point than the control, which allows for lower application temperatures. This is important when it comes to heat sensitive substrates.

[0100] Furthermore, at the same add-on level, the adhesion retention of Examples 1, 2 and 3 is significantly higher than that of H2598, both initially and after aging. Thus, the formulations of the present invention provide substantially lower viscosity, better creep resistance than currently avail...

Embodiment 2

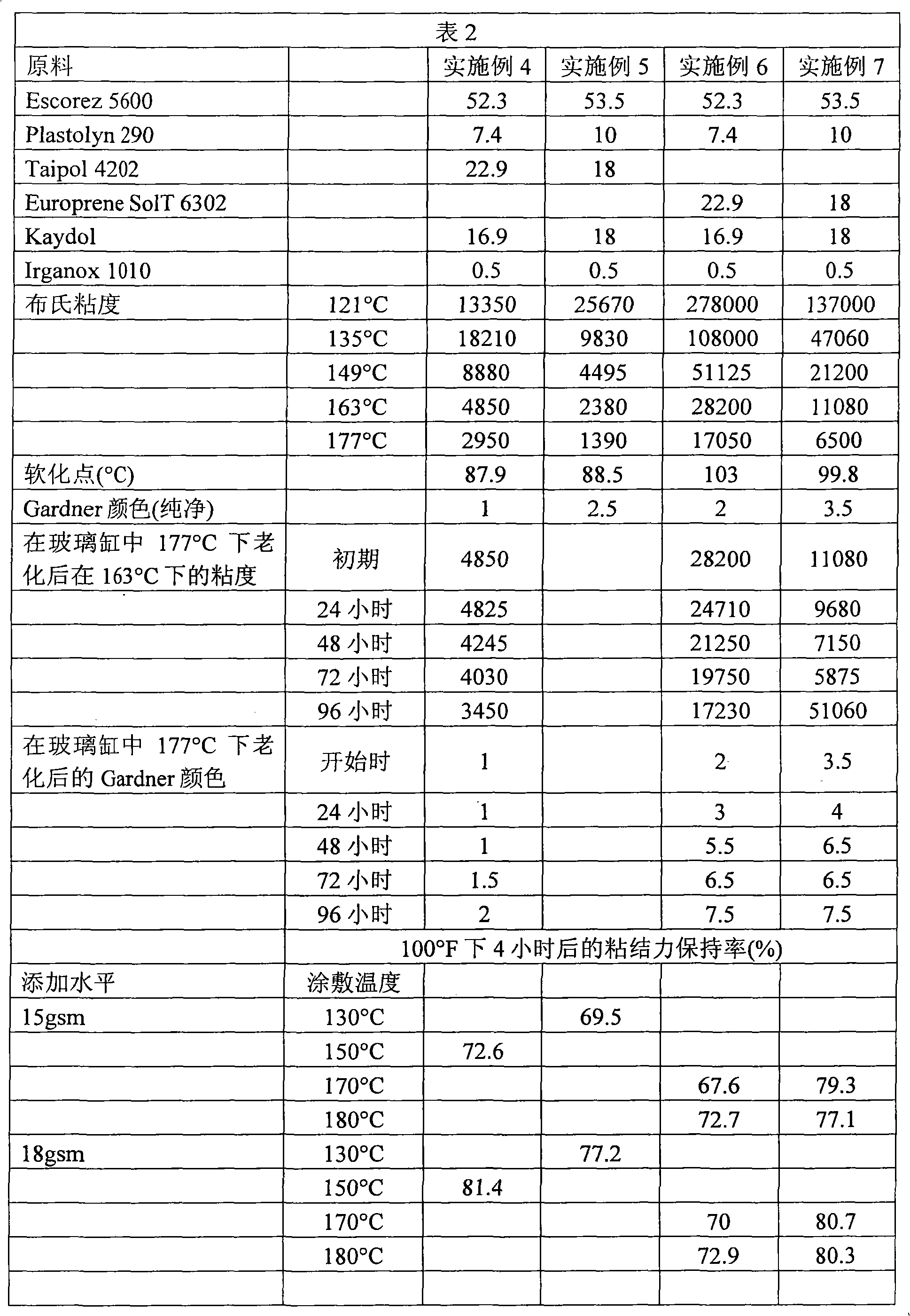

[0103] Referring now to Table 2, Examples 4 and 5 are formulations made according to the present invention. Examples 6 and 7 are the same formulation except using the SBS polymer described in US 6,391,960 which is a SBS based polymer containing 30% by weight styrene. Also, it should be noted that Example 7 is similar to Formulation I-2 in Table I of US 6,391,960 and Example II-2 in Table II.

[0104] It should be noted that from the comparison of the formulations of Example 4 and Example 6 and the comparison of the formulations of Example 5 and Example 7, it is evident that the viscosity of the present invention (Examples 4 and 5) is significantly lower (about 4- 6 times) the formulations in Examples 6 and 7 described in the prior art US 6,391,960. As a result, the lower viscosity formulations of the present invention (Examples 4 and 5) allow them to be sprayed onto elastic strands at significantly lower temperatures (about 130°C to about 150°C), whereas prior art US 6,391,96...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com