Vacuum steam cleaner

A vacuum cleaner and steam technology, applied in vacuum cleaners, suction filters, cleaning equipment, etc., can solve the problems of large storage space, insufficient steam storage space, steam leakage, etc., to improve the convenience of use, reduce the space required for storage, Easy loading and unloading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

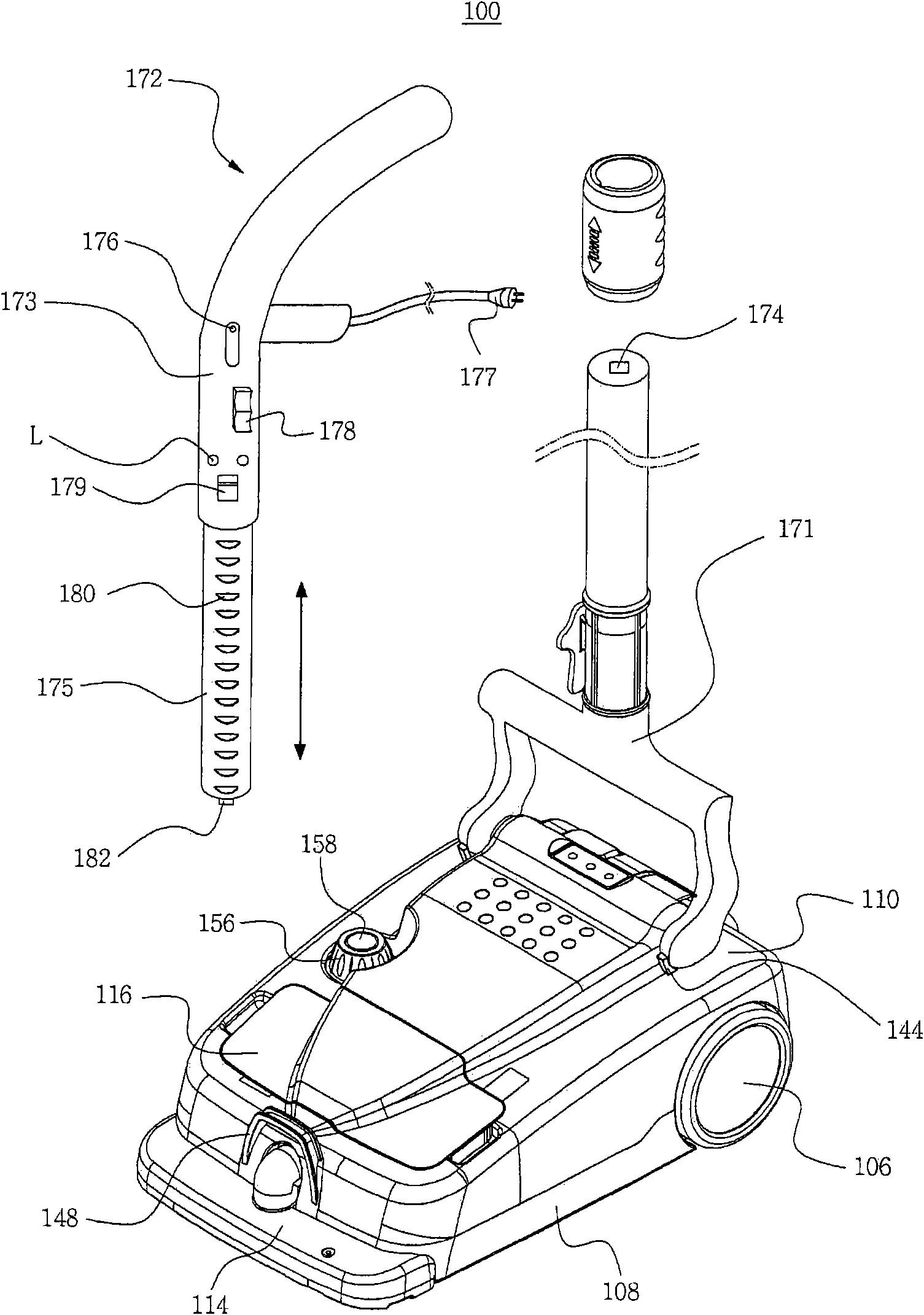

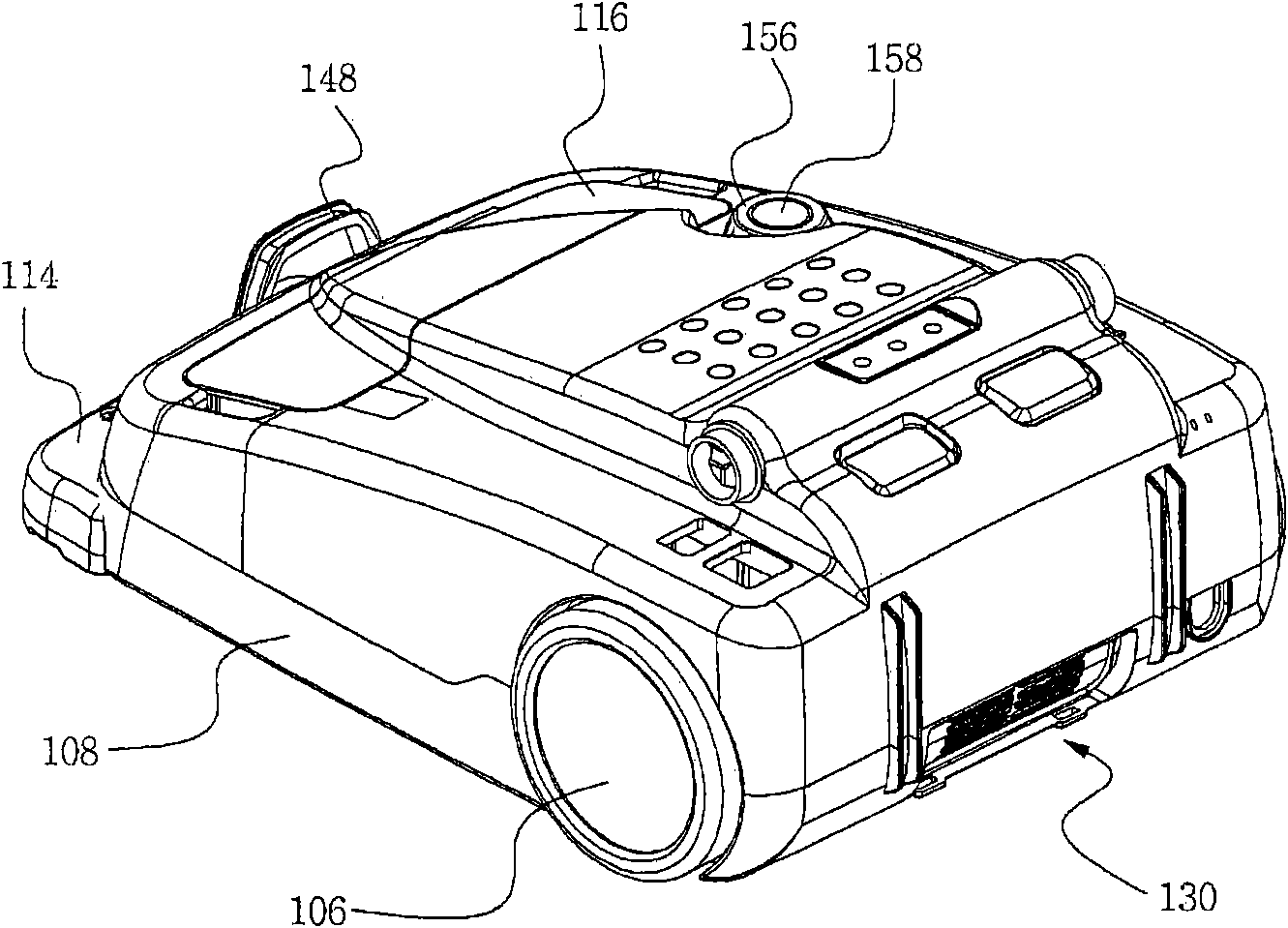

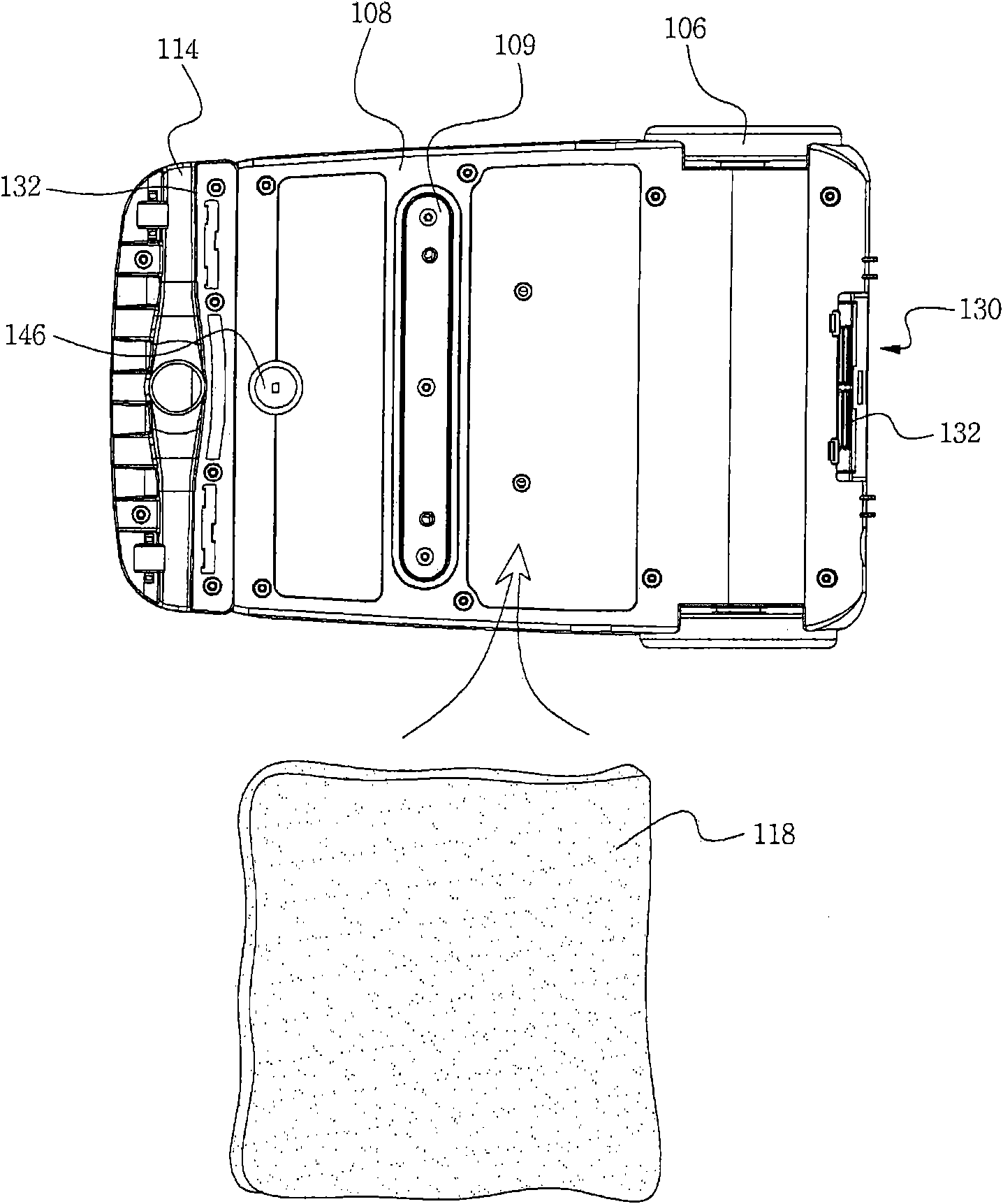

[0034] In order to achieve the above object, the vacuum steam cleaner of the present invention includes: a main body with moving driving wheels on both sides of the rear; a steam generating unit built in the inside of the above-mentioned main body, but installed in front of the motor in order to generate suction force, and can store water And heat the stored water to generate steam; the collection part is located in front of the above-mentioned steam generating unit, and absorbs impurities by the rotation force of the above-mentioned motor; the dust collection unit collects the impurities accumulated in the above-mentioned collection part; and the blowing unit The wind generated after the operation of the motor is guided to the ground to dry the ground, and the above-mentioned steam generating unit, collecting part, dust collecting unit and the above-mentioned motor are located on the same plane, and it is characterized in that it includes the following units: a steam storage an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap