Full-automatic fixed-length cutting device of metallic hose

A metal hose and cutting device technology, applied in positioning devices, pipe shearing devices, shearing devices and other directions, can solve the problems of slow production speed, poor product consistency, low efficacy, etc., to improve production efficiency and product consistency high sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

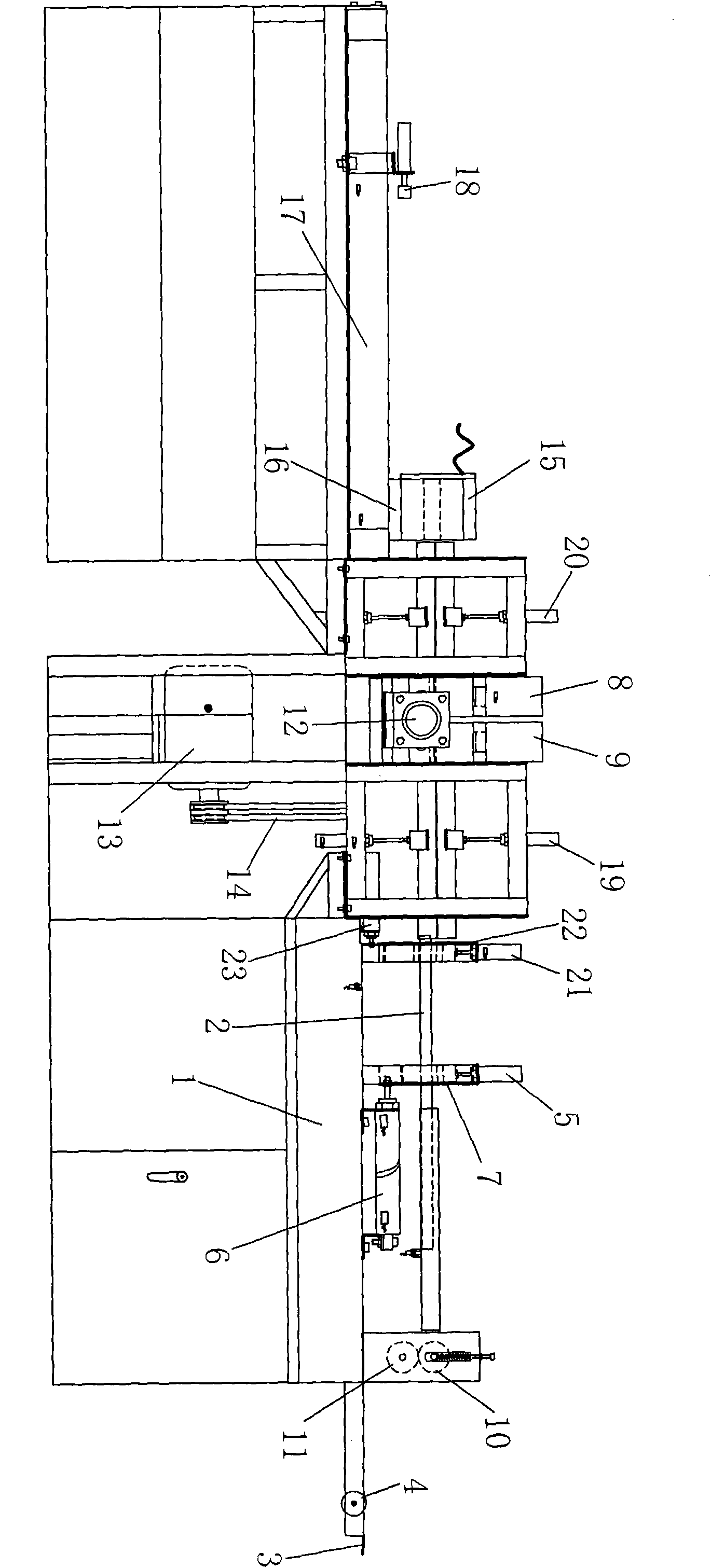

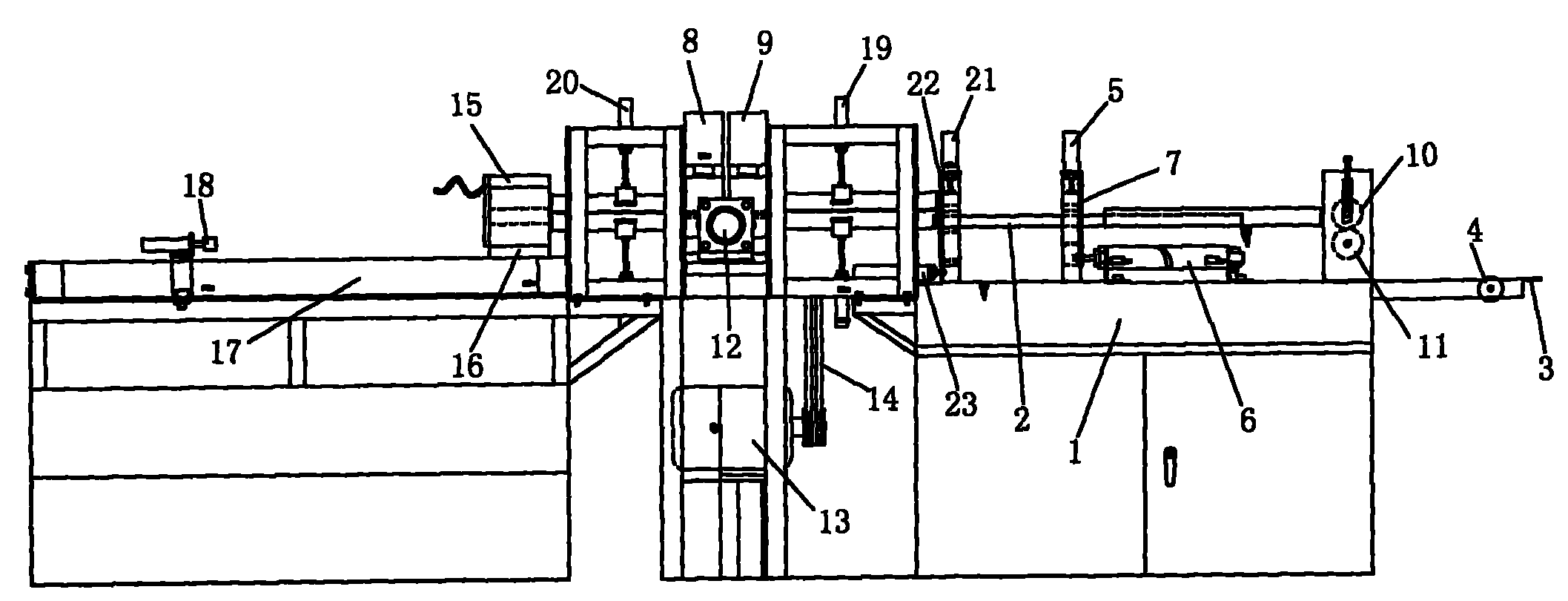

[0020] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

[0021] Reference figure 1 , A metal hose automatic fixed-length cutting device, comprising a machine base 1, a strip conveying table 2 erected on the machine base 1 for conveying metal hoses, and the strip conveying table 2 vertically There is a feeding trough throughout. In this embodiment, the cross section of the conveying trough of the strip-shaped conveying platform 2 is V-shaped, and the conveying trough is also covered with a number of positioning covers. The function of the positioning covers is to transport the metal hose. Prevent arching of the metal hose.

[0022] In the feeding direction: the tail of the strip conveyor 2 is provided with an inlet 3, and the inlet 3 is provided with a feeding pulley 4, and the purpose of setting the inlet 3 and the feeding pulley is to make The metal hose can be introduced into the conveying tank more smoot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com