Cutter feeding device with controllable pressure angle

A technology of feeding device and pressure angle, which is applied in the direction of feeding device, manufacturing tools, metal processing machinery parts, etc., can solve the problems of poor processing surface quality, vibration, etc., and achieve the effect of compact structure and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

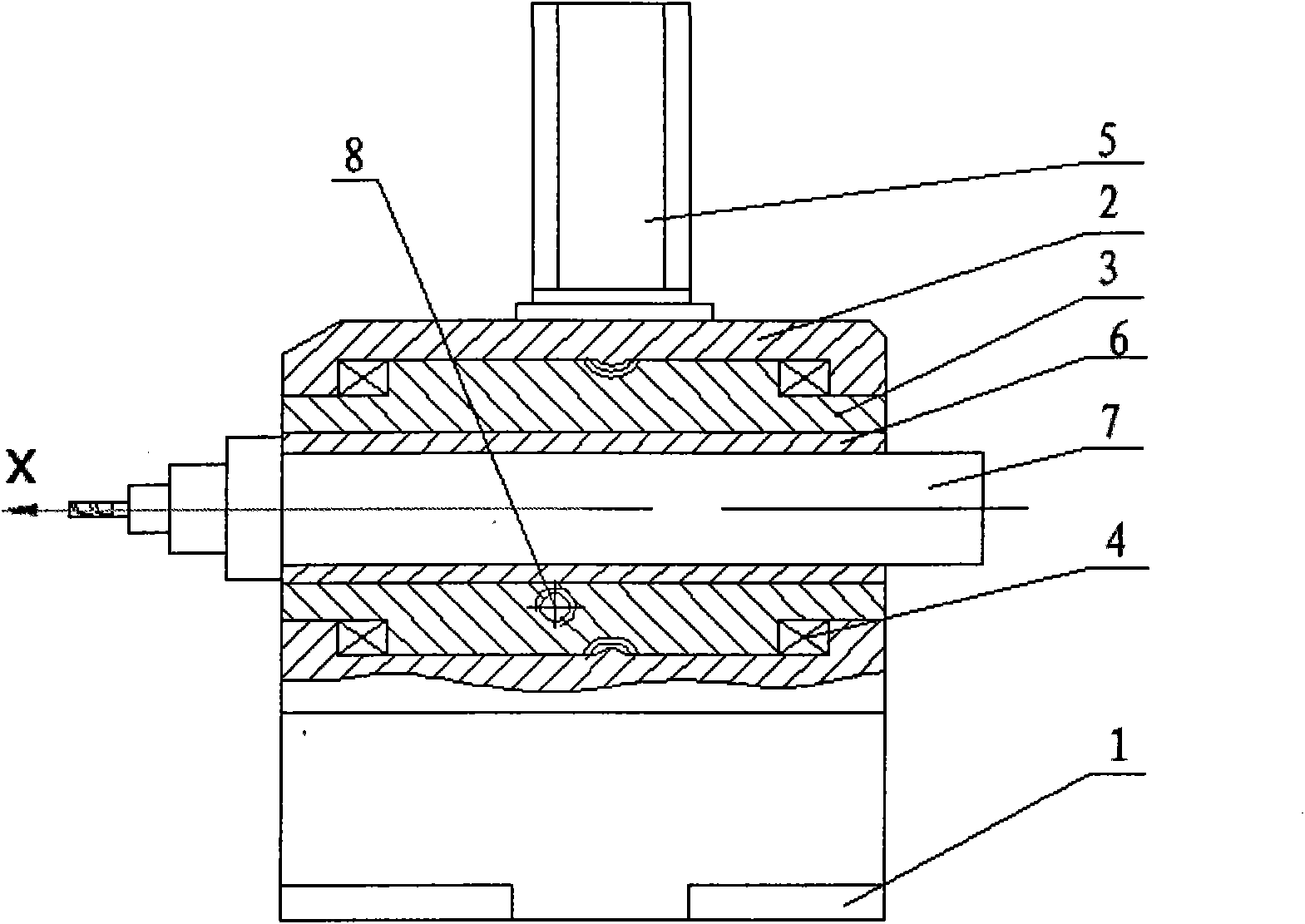

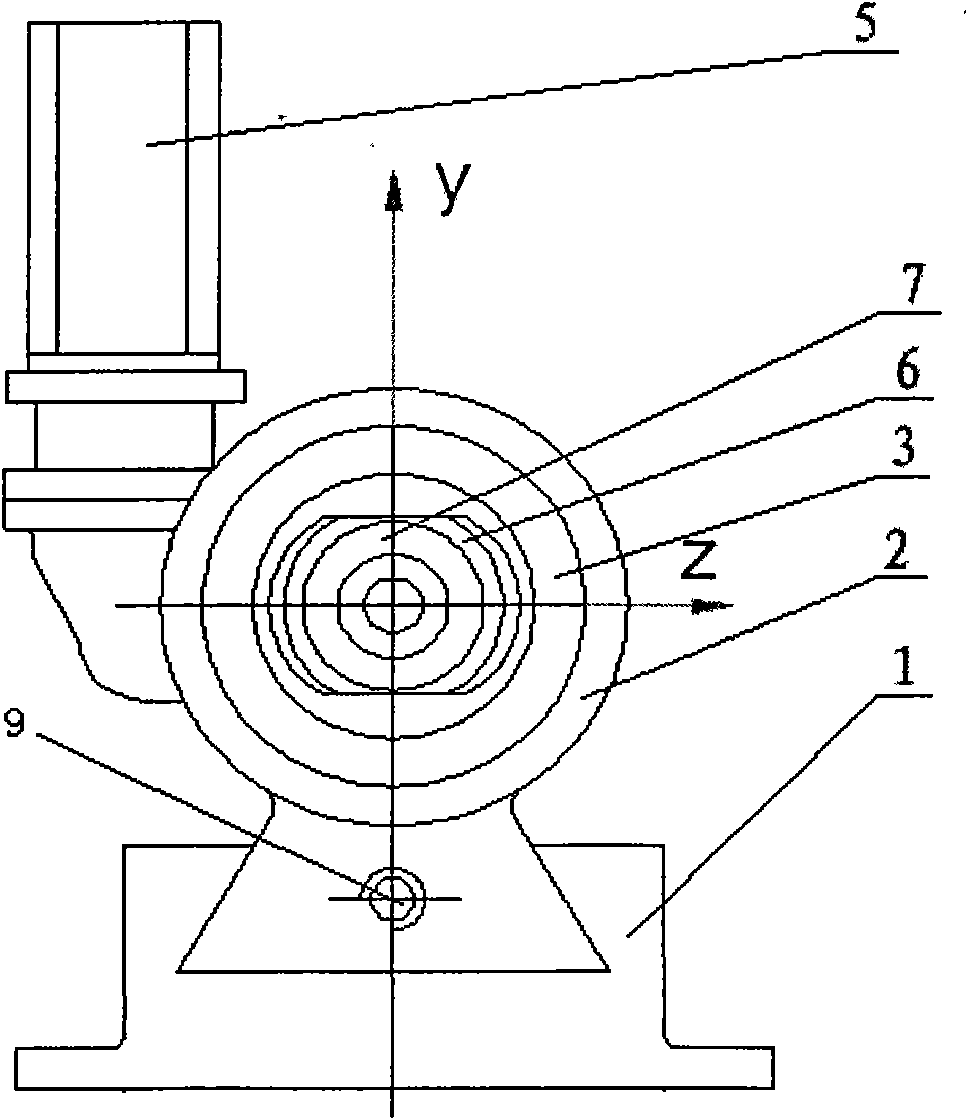

[0012] Referring to the accompanying drawings, a tool feeding device with controllable pressure angle includes a base 1 on which a housing 2 with a dovetail groove is slidably installed, and a main screw 9 passes through the housing 2, and the main screw 9 passes through the housing 2. The screw 9 drives the casing 2 to move longitudinally, and the worm wheel 3 is installed in the casing 2 through the rotation of the bearing 4, and a vertical worm shaft is installed on one side of the casing 2 to mesh with the worm wheel 3, and a control motor 5 drives the worm shaft Adjust the pressure angle of the cutter; a slide block 6 that can slide horizontally is installed in the inner hole of the worm wheel 3, and a horizontal lead screw 8 passes through the worm wheel 3, and the two ends of the lead screw 8 are rotated and installed in the worm wheel 3, and the thread on the lead screw 8 Fitted with a nut, the nut can drive the slide block 6 to slide left and right, and the electric sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com