Heating decontamination system of full automatic foam plastic forming machine of two opposite-clamping type templates

A technology of foam plastics and sewage system, which is applied in the field of bottom steam heating system, can solve the problems affecting heating speed, etc., and achieve the effect of improving vacuum effect, reducing production cost and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

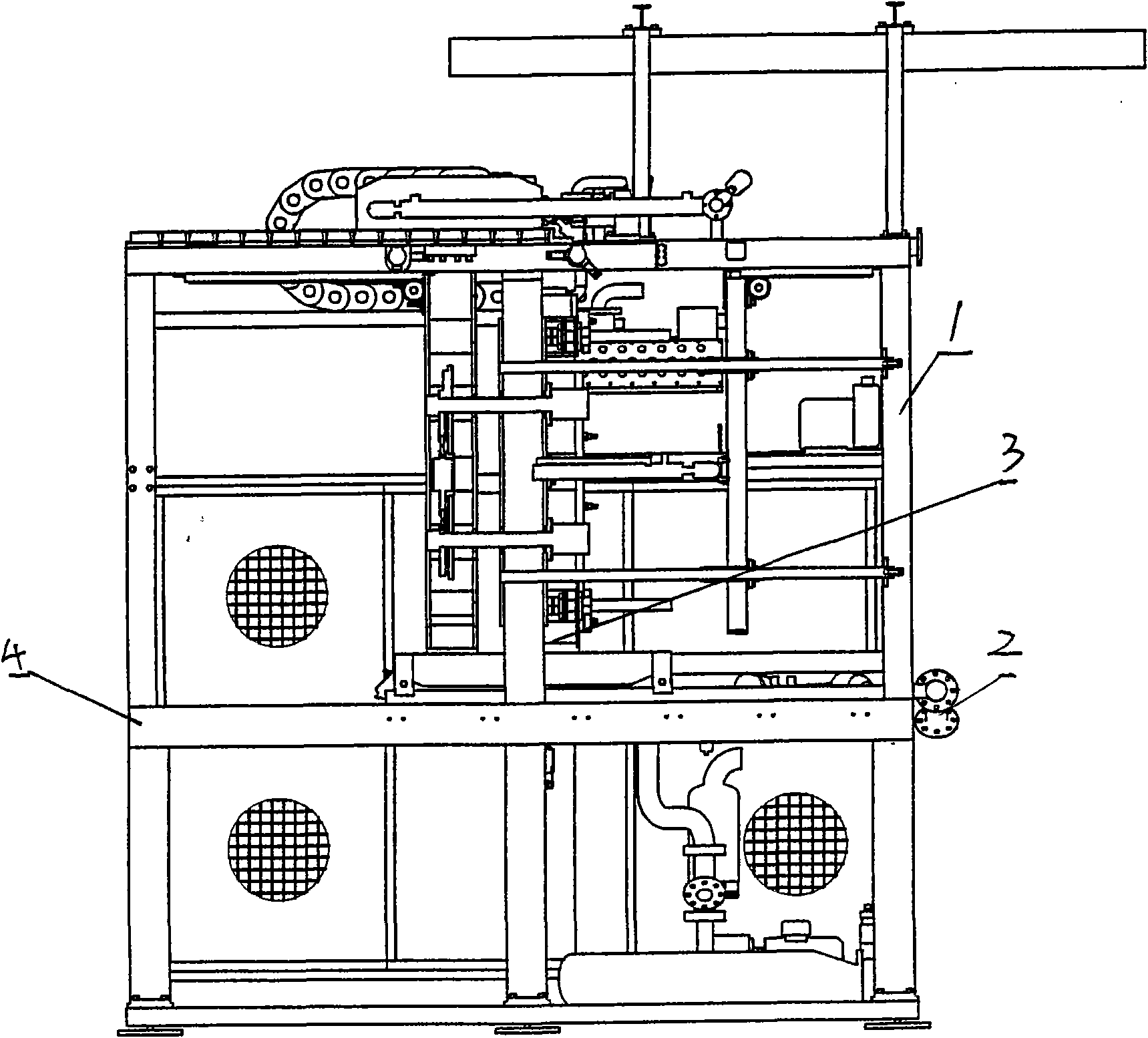

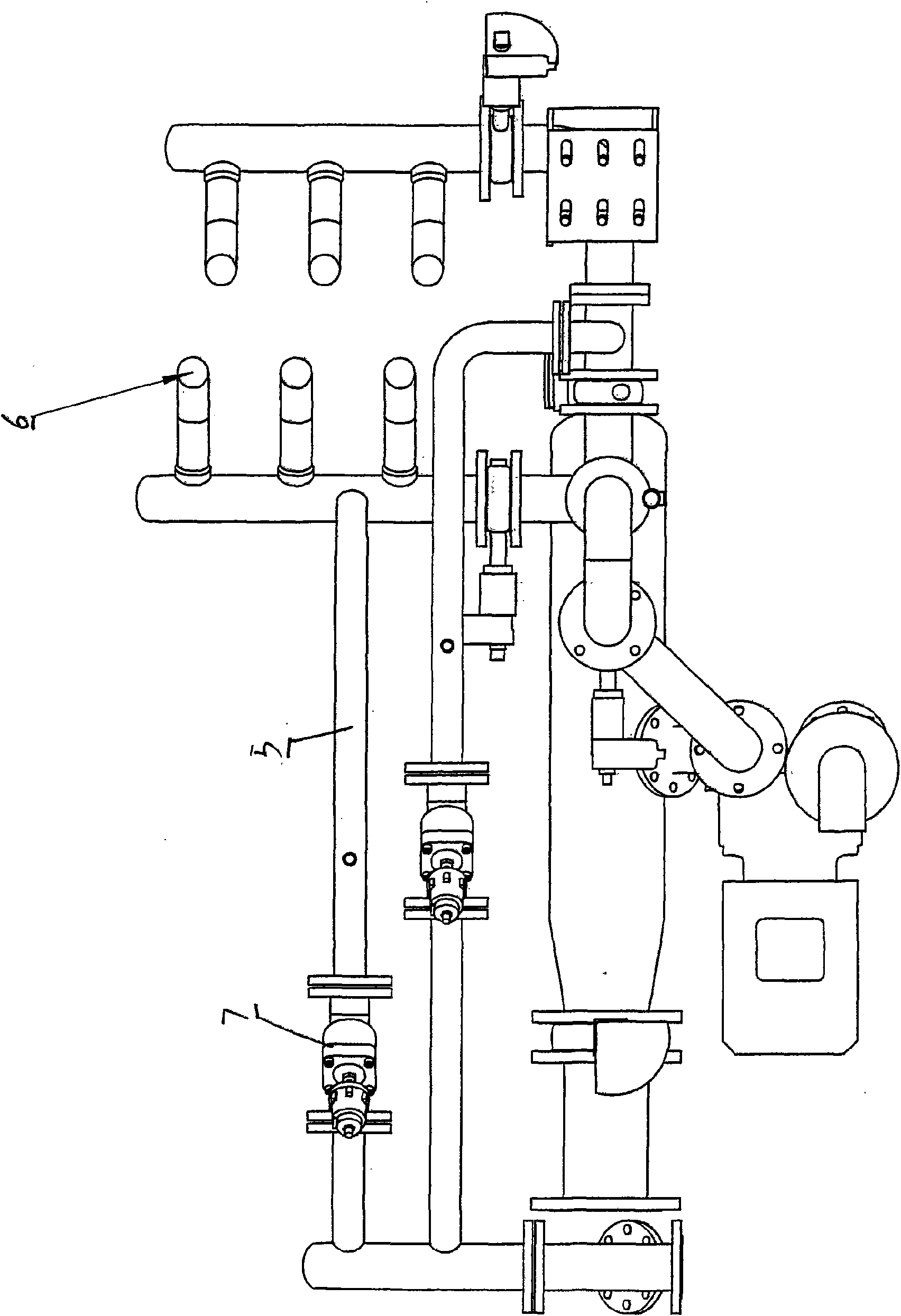

[0018] Such as figure 1 , figure 2 As shown, the bottom steam heating system 2 of the clamp-type two-platen automatic foam molding machine 1 is located at the bottom of the frame frame 4 and the bottom of the formwork 3; the steam heating system is connected by a hard pipe 5 . The caliber 6 of the bottom steam heating system entering the mold is larger than the caliber of the steam valve 7 . Bottom steam heating is more in line with thermodynamic principles, and the change of caliber makes the heating speed faster.

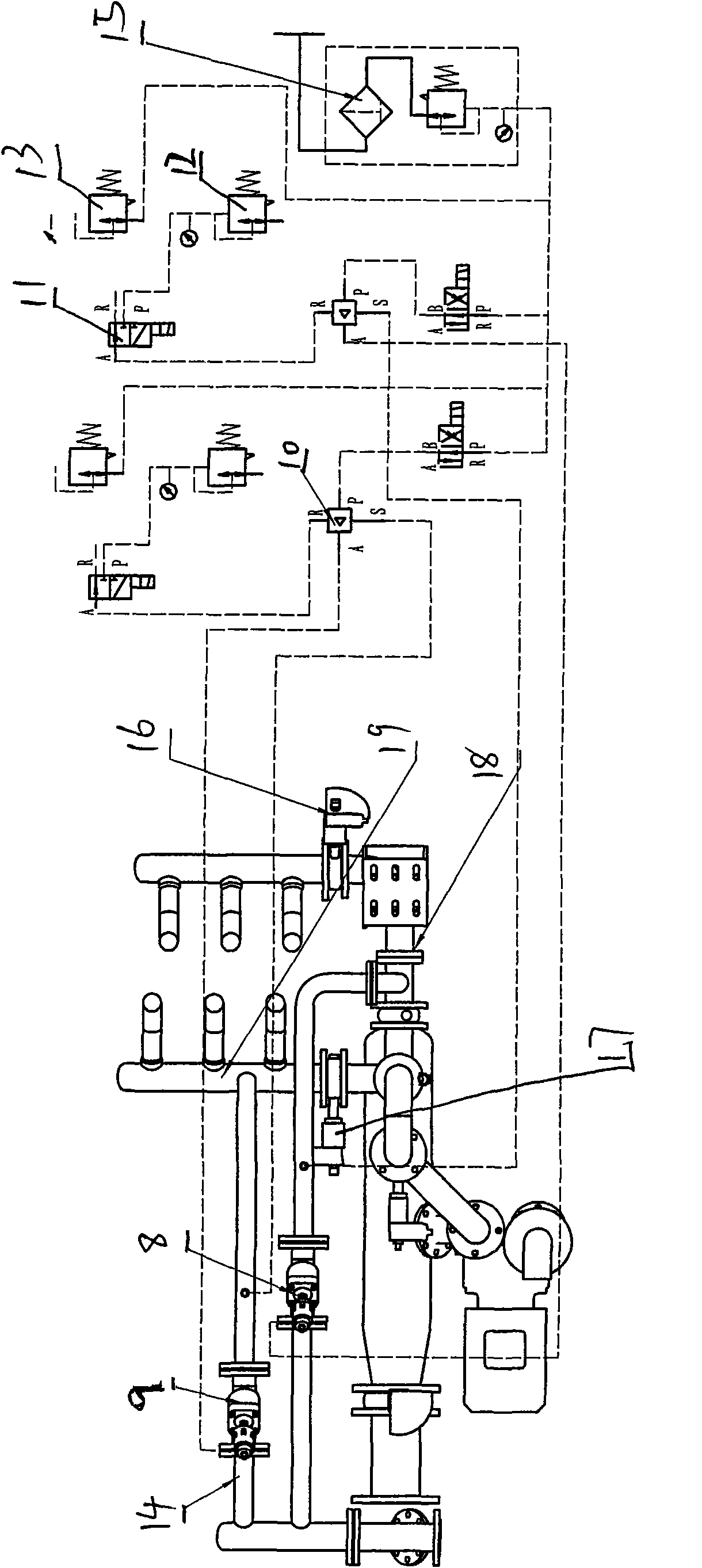

[0019] Such as image 3 As shown, the pulse steam heating stage conversion system of the automatic foam molding machine is equipped with a moving mold steam valve 8 and a solid mold steam valve 9. The moving and solid mold steam valves are controlled by a balance valve 10, and the balance valve passes through the reversing valve 11 connects two compressed air pressure regulating valves 12,13. There are also solid mold steam pipes 14, gas source treatment trip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com