Queuing mechanism, queuing device and queuing system for solid substances on conveying belt

A technology of solid material and queuing mechanism, which is applied to conveyor objects, transportation and packaging, sorting, etc., and can solve the problem that the queuing distribution law cannot be changed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

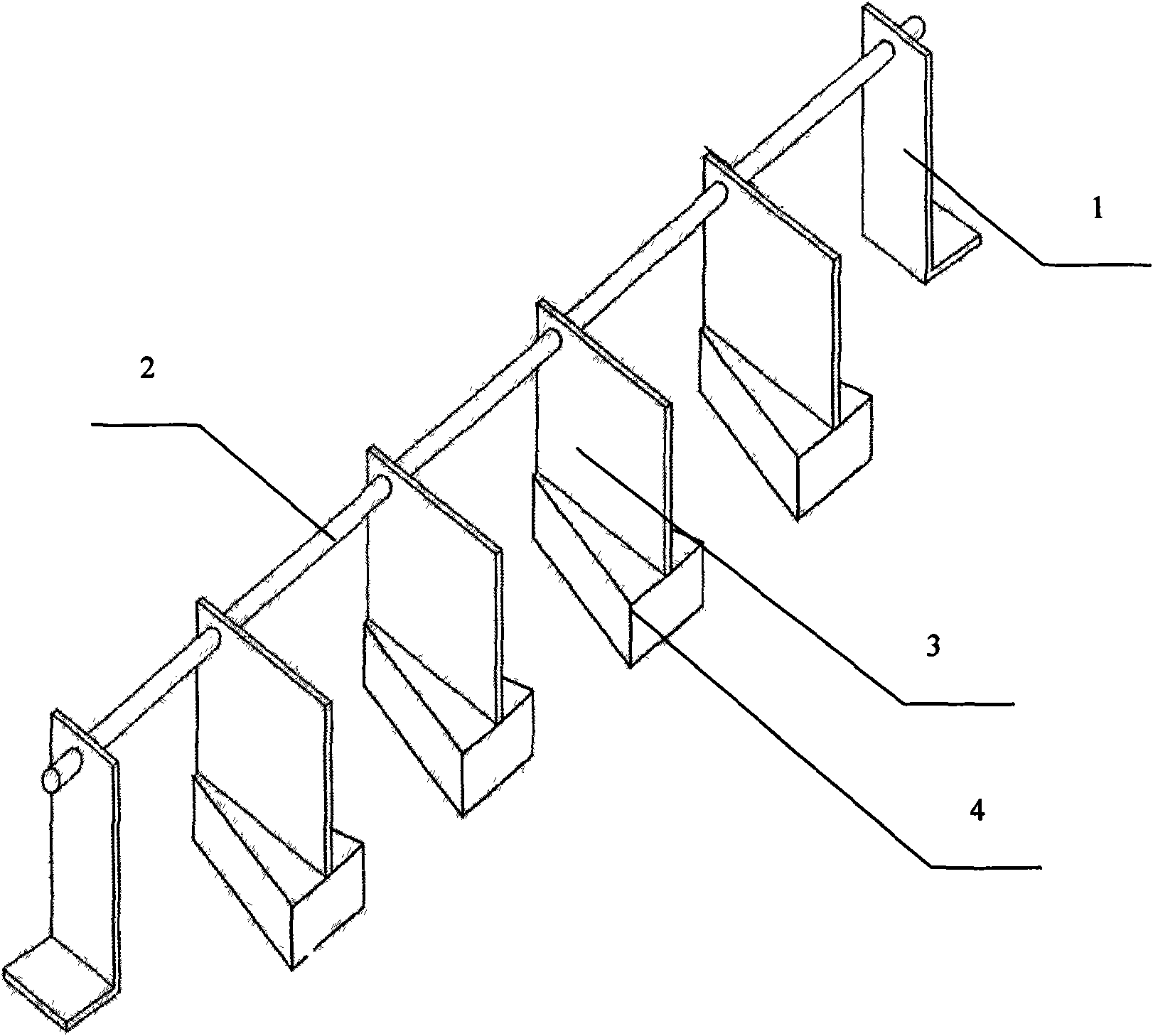

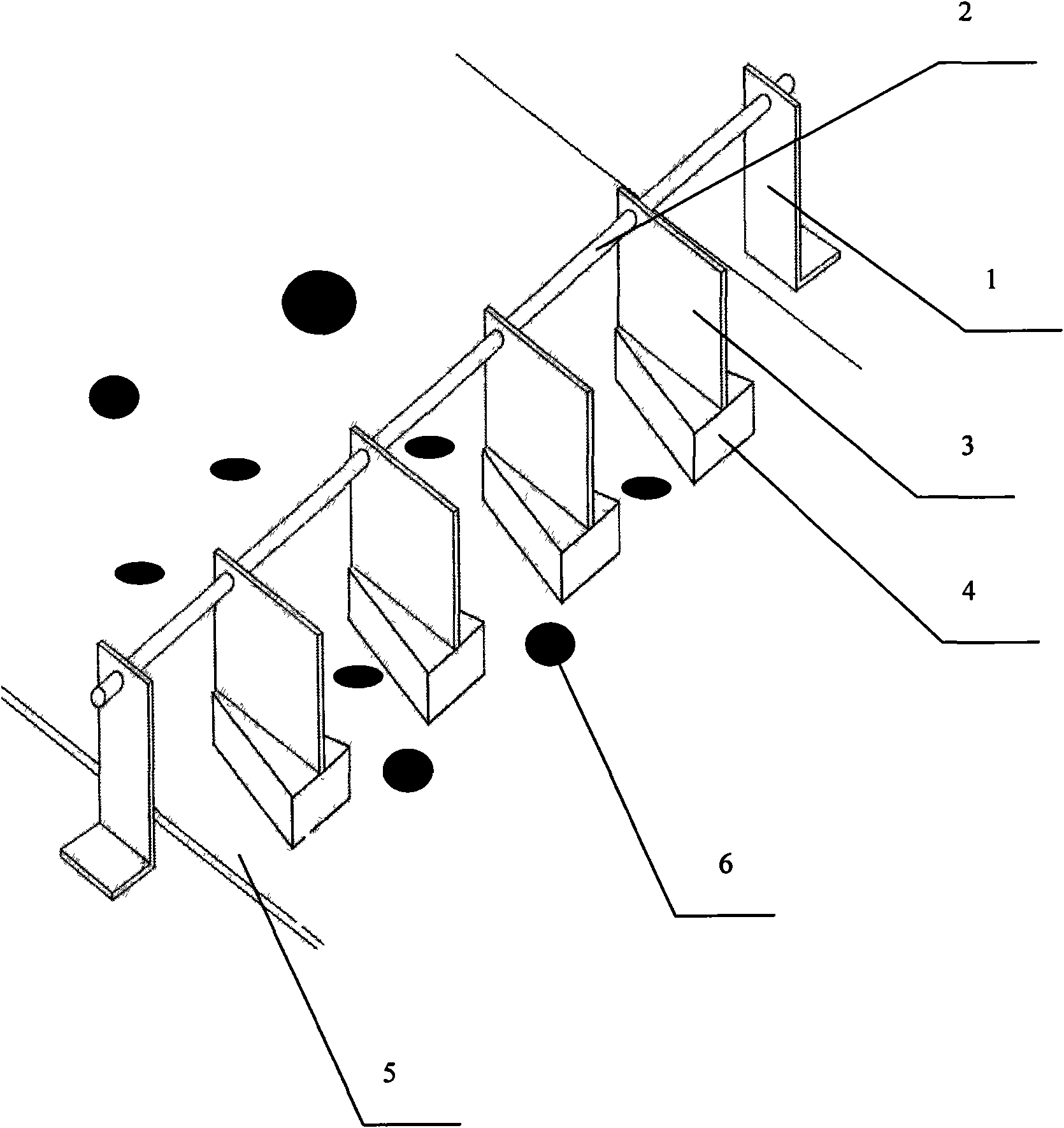

[0023] Such as figure 1 As shown, a queuing mechanism for solid substances on the conveyor belt includes two side brackets 1, a horizontal bar 2 connected to both sides of the brackets and a queuing plate 4 with a support plate 3, and one end of the support plate 3 is connected to the queuing plate It is fixedly connected, and the other end is socketed with the horizontal bar 2 and can rotate around the horizontal bar. There are four queuing boards 4 with support plates 3, and the queuing boards 4 are gradual widening boards with a width from small to large. Such as a triangle or an isosceles triangle, it can also be a streamlined gradually widening board on both sides of the width, and the two ends of the horizontal rod 2 are in a height-adjustable flexible connection with the brackets 1 on both sides. Such as figure 2 As shown, when the solid matter 6 is transported on the conveyor belt 5, it is divided into five rows by the separation of four queuing plates, and the width...

Embodiment 2

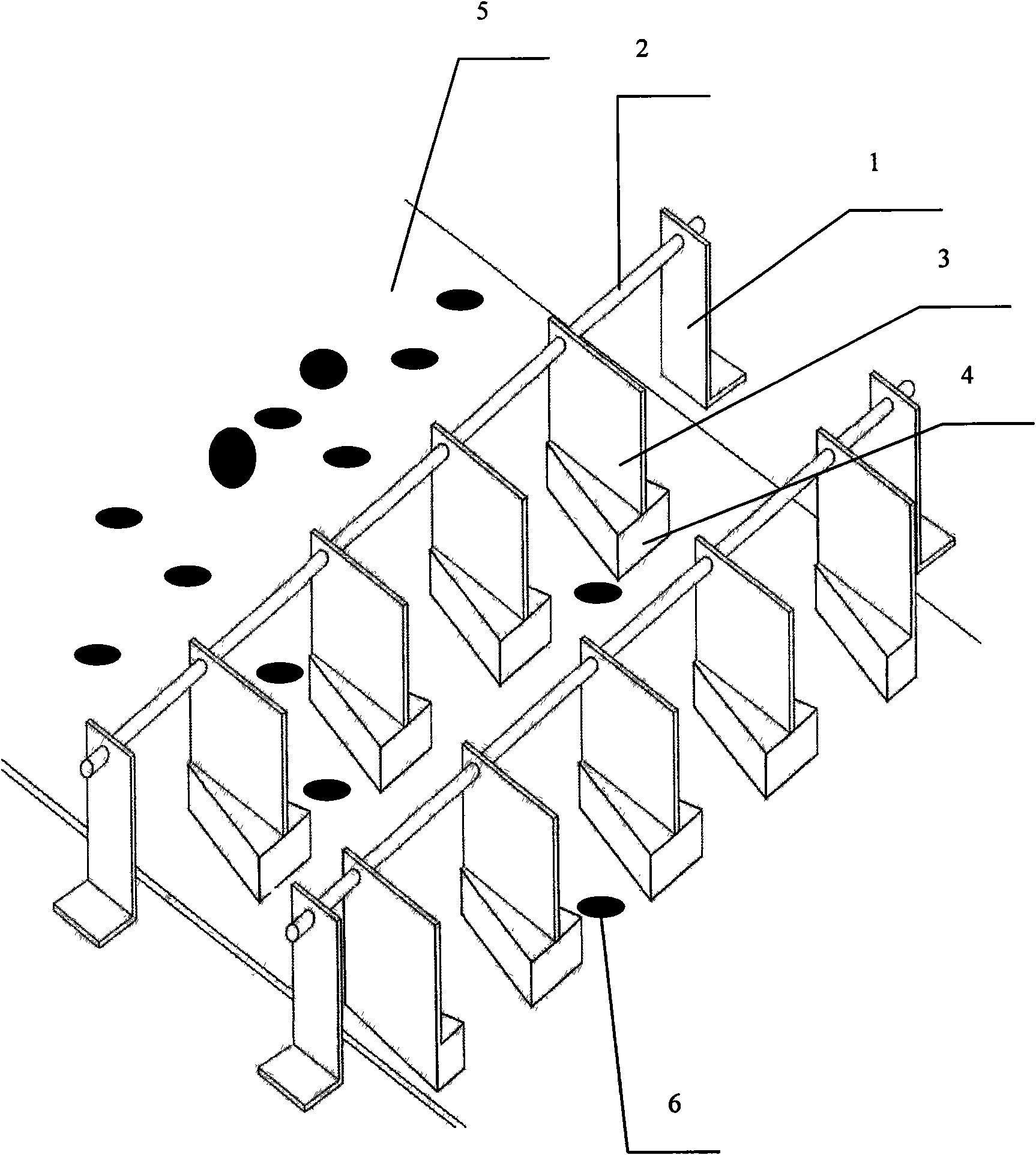

[0025] Such as image 3 As shown, a queuing device for solid substances on the conveyor belt includes front and rear two queuing mechanisms for solid substances on the conveyor belt described in the first embodiment above, and the front and rear two solid substances are on the conveyor belt. The queuing plates in the queuing mechanism are arranged in a staggered manner, and the queuing plates in the queuing mechanism of the front and rear solid materials on the conveyor belt are triangles with equal apex angles.

Embodiment 3

[0027] Such as Figure 4 Shown, a kind of queuing system of solid matter on the conveyer belt comprises front and back two queuing devices of solid matter on the conveyer belt, and the queuing device of front and rear two solid matter on the conveyer belt is all the same as embodiment two The same queuing mechanism as described in Figure 5 , 6 As shown, the top angles of the queuing boards of the front and rear solid matter queuing devices on the conveyor belt are arranged from large to small according to the conveying direction of the conveyor belt. When the solid substance 6 is transported on the conveyor belt 5, it is first received by the first The three queuing boards of a queuing device divide the solid matter into four columns, and the width of the column decreases with the shielding of the triangular queuing boards, and is then affected by the three queuing boards of the second queuing device. Separation, because the top angle of the queuing plate of the second queu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com