Automatic needle-turning and loop-transferring flat machine

A technology of automatic turning and knitting flat knitting machine, which is applied in the direction of flat knitting machine, knitting and weft knitting with separate action needles, which can solve the problems of a large number of manual operations, inability to receive flowers, and low efficiency, and achieve the effect of smooth running back and forth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Example of yarn feeder control:

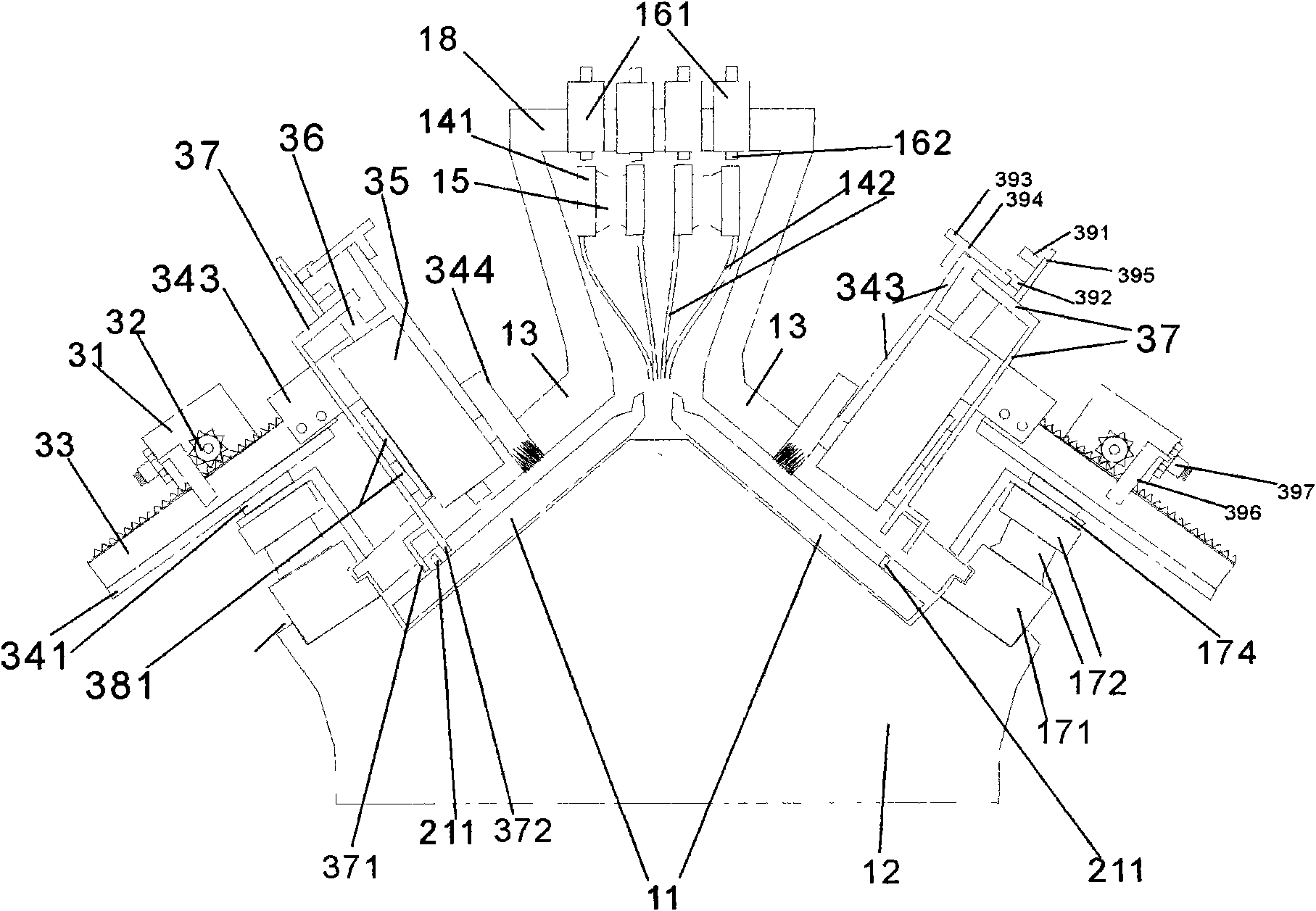

[0046] A plurality of electromagnets (161) are installed above the flyover (18) of the machine head, for controlling each yarn feeder (142), an electromagnet (161) is positioned in a yarn feeder (142) horse (141), and the electromagnet The iron core cover (162) of (161) stretches out, blocks the horse (141) on the yarn feeder (142), thereby makes the yarn feeder (142) random head movement, the iron core cover (162) of electromagnet (161) Retract, can not block the horse (141) of this yarn feeder (142), also can not drag this yarn feeder (142).

[0047] Installation example of machine head guide rail

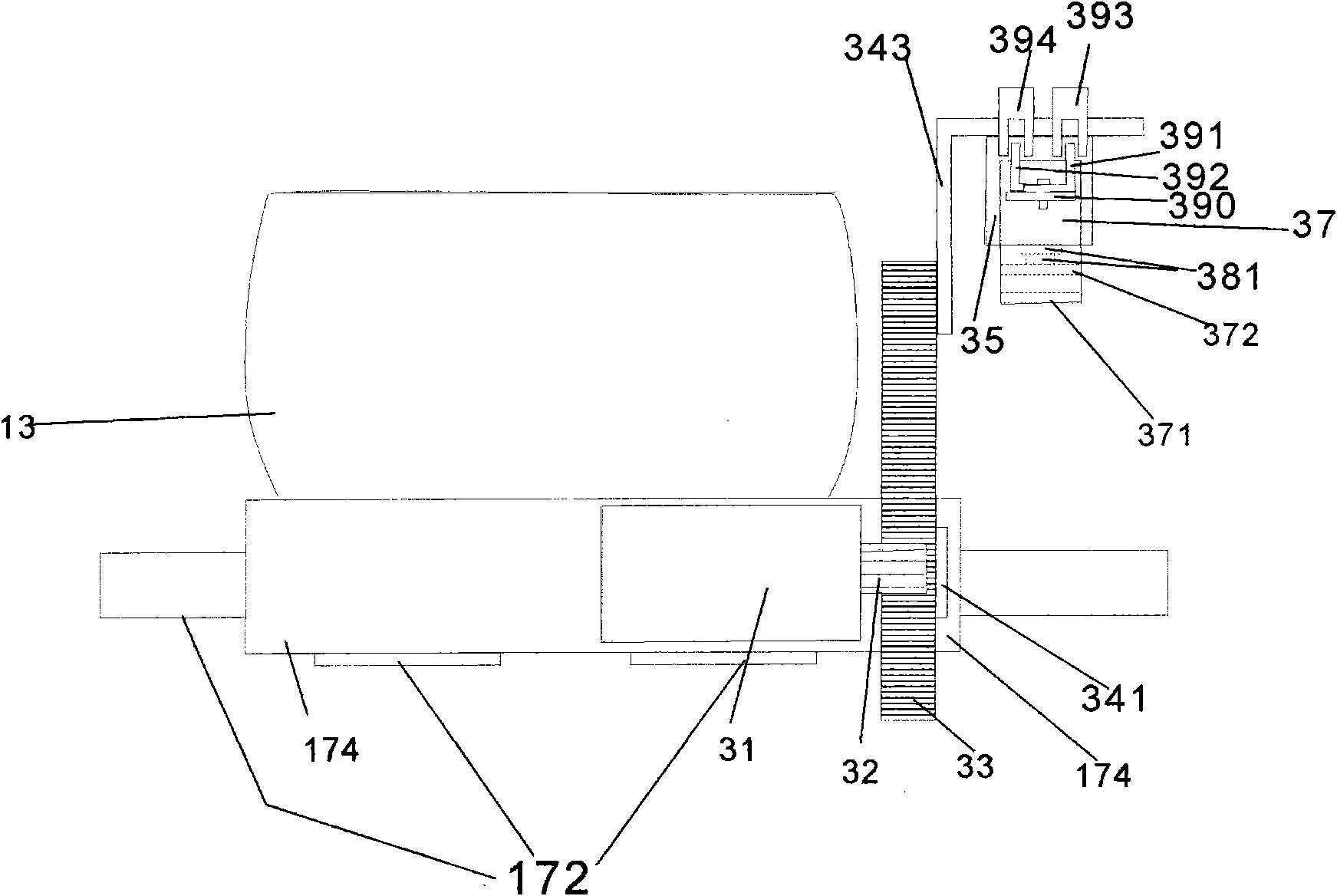

[0048]The front and back parts of the machine head (13) are all connected with the angle iron (174) of the machine head, and the angle iron (174) of the machine head is connected with the guide rail (172), and the guide rail (172) is fixed on the original guide bar (171) of the flat knitting machine, and the machine head and the movement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com