Hygrostat water tank and hygrostat

A technology of a constant humidity machine and a water tank, which is applied in the directions of household heating, space heating and ventilation details, heating methods, etc., can solve the problems of increasing product packaging, transportation costs, inconvenient pouring or adding water, and many product parts, etc. Achieve the effect of compact structure, simplified structure and reduced product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

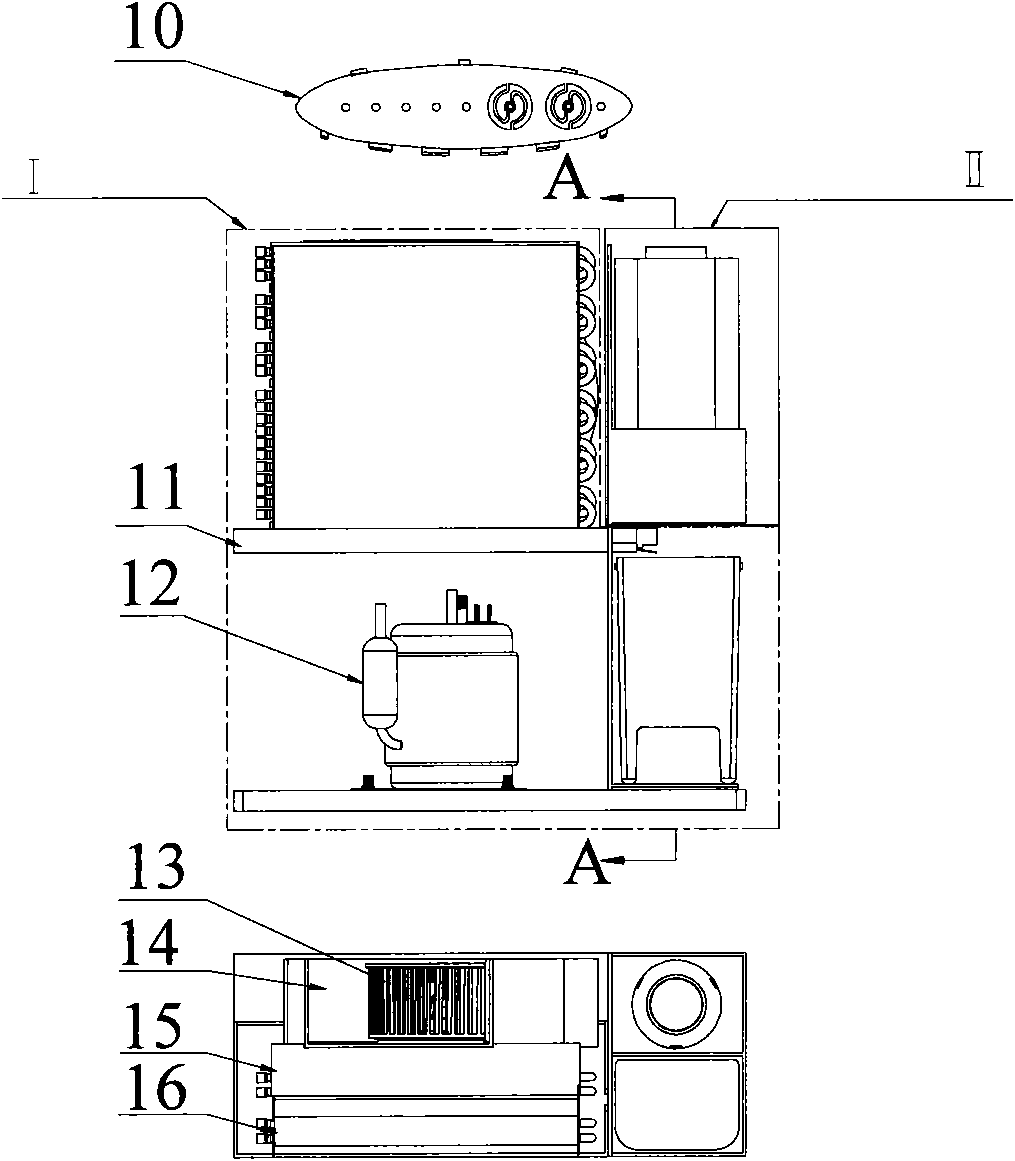

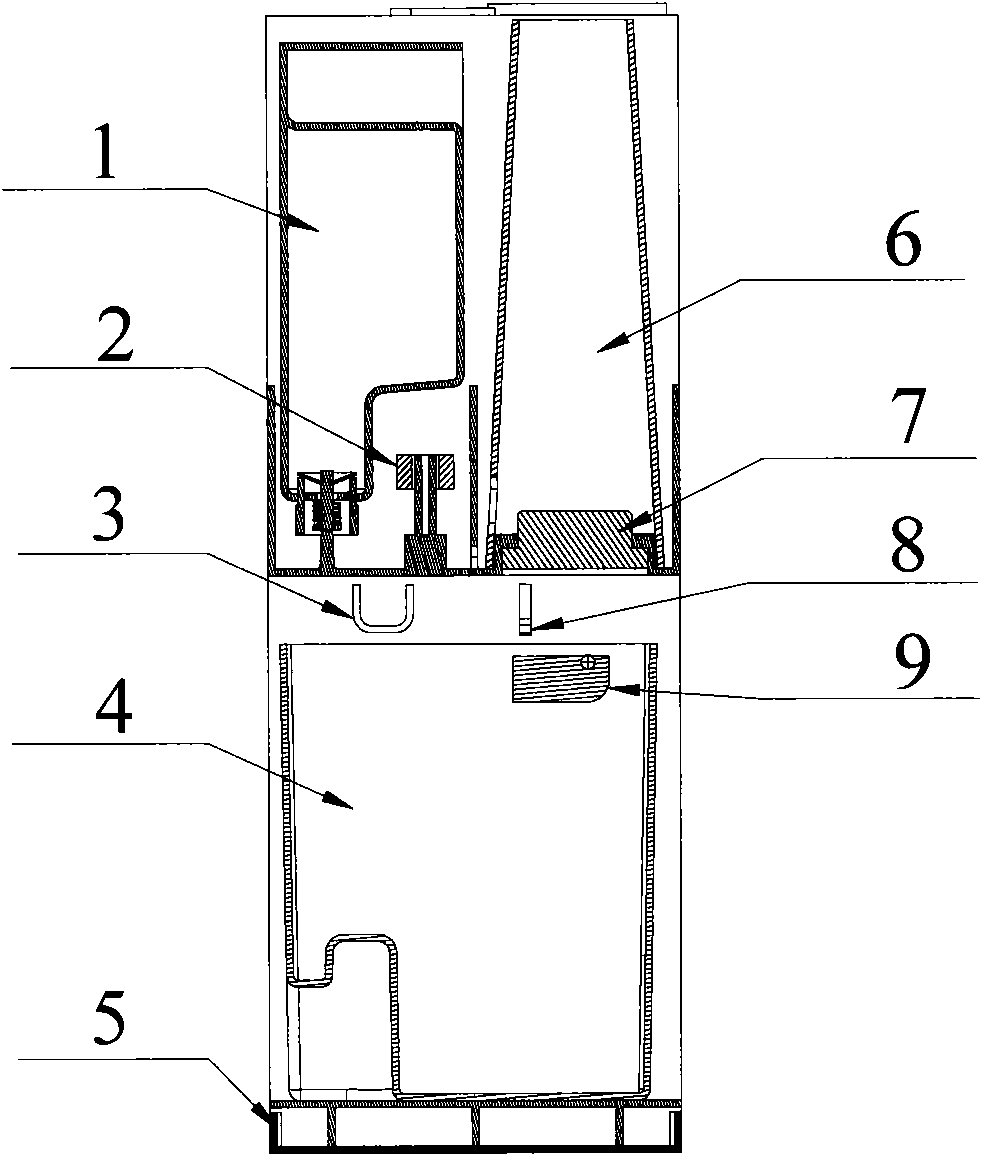

[0041] The basic concept of the present invention is to combine the humidification and dehumidification water tanks into one, so that the water tanks can be used in both the dehumidification mode and the humidification mode.

[0042] The following will be described in detail in conjunction with the accompanying drawings and embodiments.

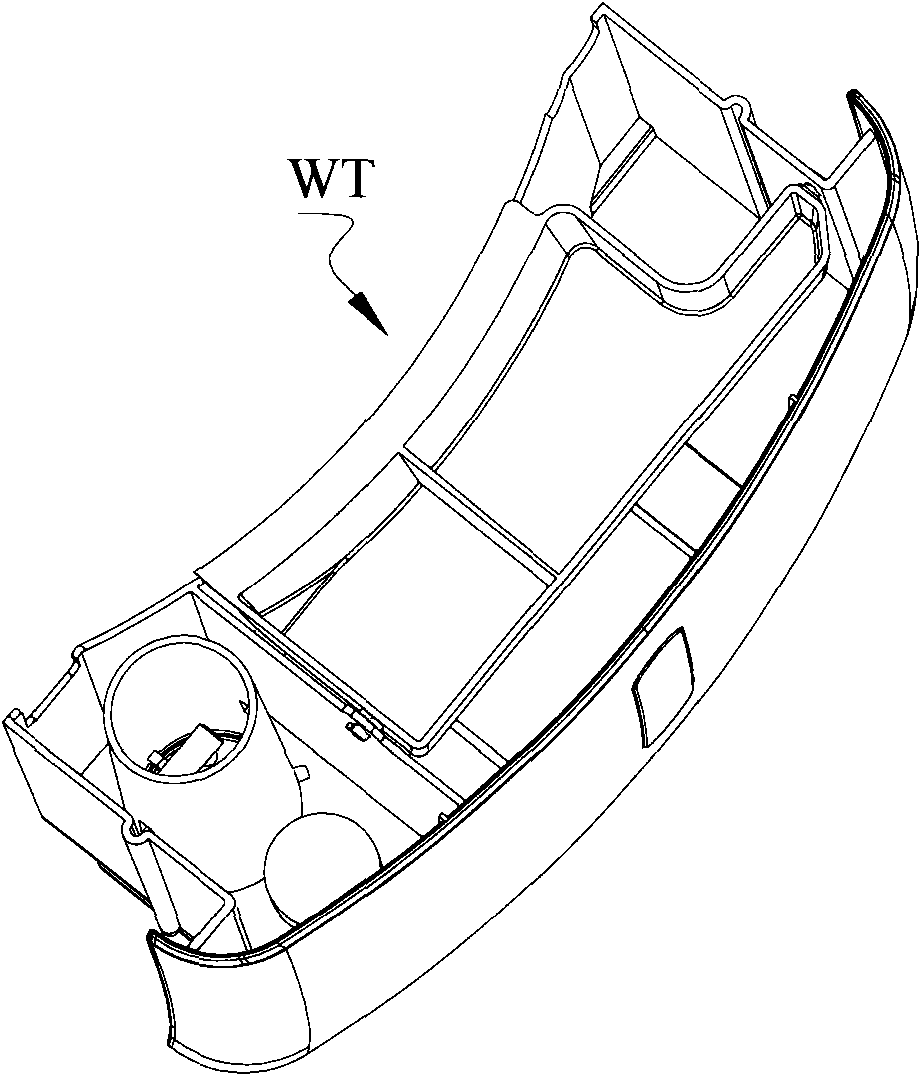

[0043] see Figure 3-Figure 6 , the water tank WT in the described embodiment mainly includes main components such as a water tank body 19, a dehumidification water float 9, a humidification water float 20, a sealing ring 21, a mist guide tube 6, and an ultrasonic atomizer 18, wherein the inside of the water tank body 19 has The position of ribs in the water tank is 22, and the water tank WT is divided into left and right two boxes:

[0044] Right casing is useful for dehumidification, and dehumidification water float 9 is housed above, touches water level switch 2 alarms by it when dehumidification water is full.

[0045] The left and righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com