Coke particle baking startup method for pre-baked anode aluminum electrolytic cell and structure thereof

A technology for firing start-up and aluminum electrolytic cells, which is applied in the field of coke particle roasting start-up method and structure of pre-baked anode aluminum electrolytic cells, which can solve the problems of affecting the working life of electrolytic cells, easy to produce early leaks, and lining damage, etc., and achieve shortening Effects of abnormal period, small deformation, and life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

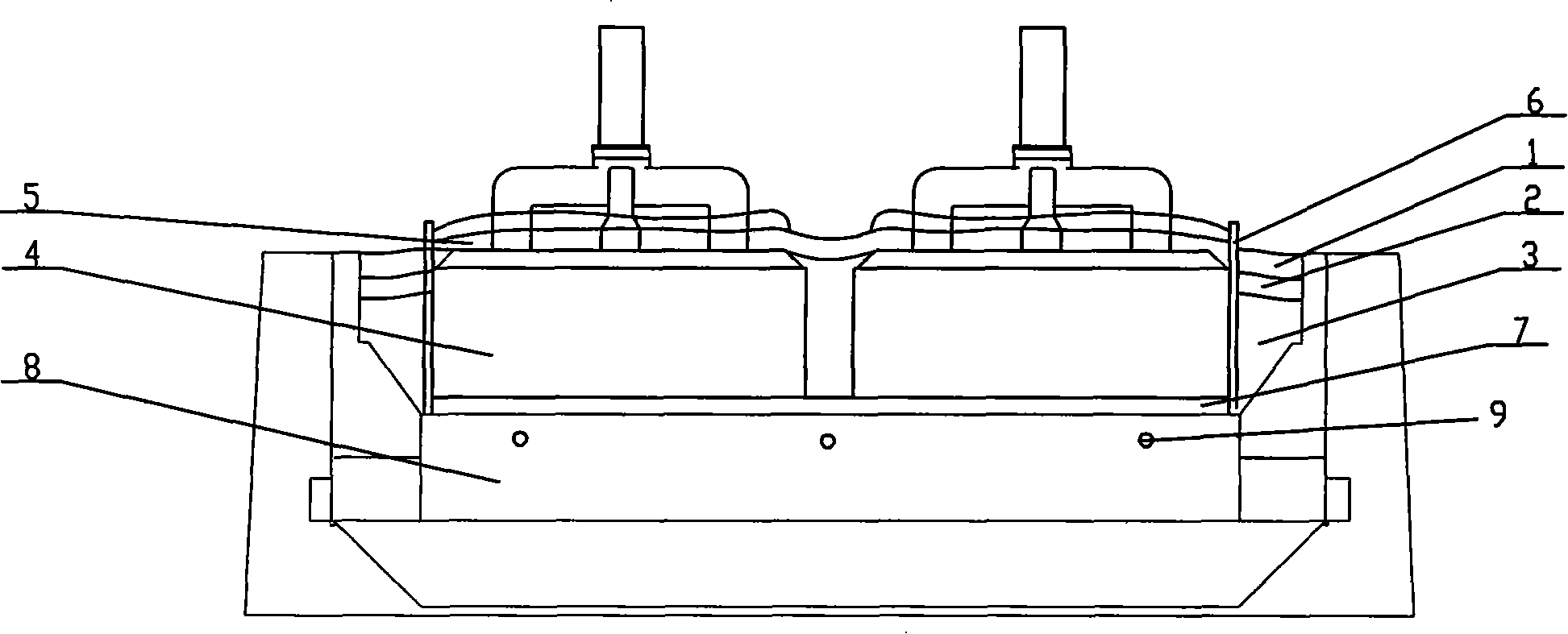

[0038] The present invention will be further described below in conjunction with accompanying drawing.

[0039] A method for starting the roasting of coke grains in a prebaked anode aluminum electrolytic cell, comprising the following steps: a step of installing a thermocouple, a step of laying coke grains, a step of charging a furnace, and a step of roasting control;

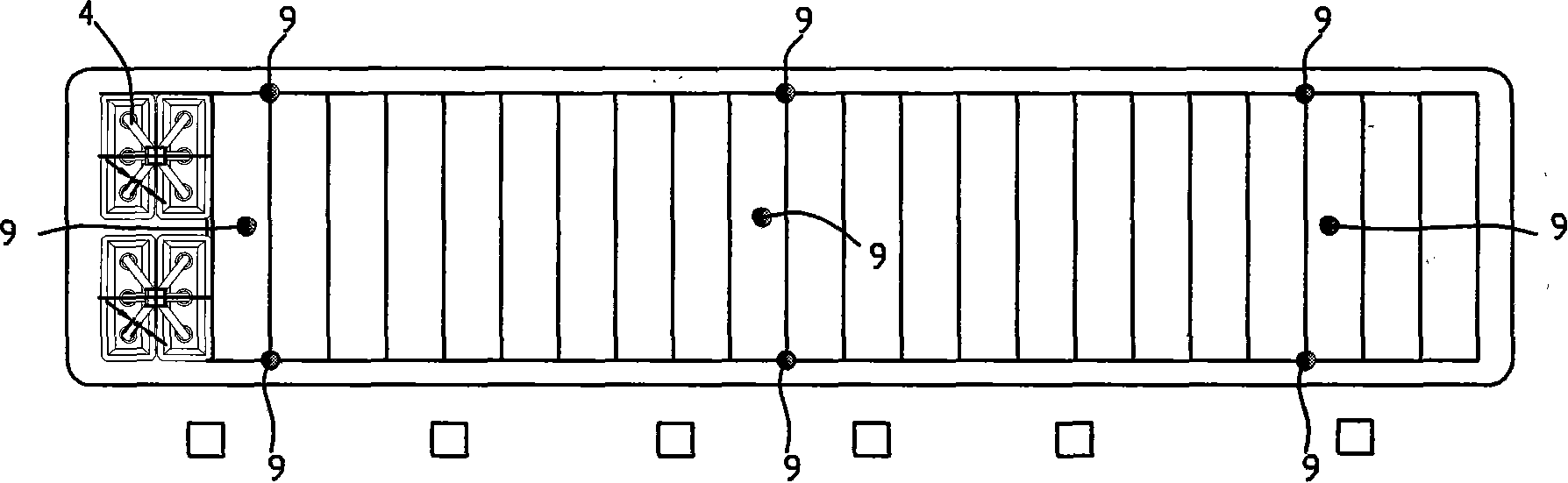

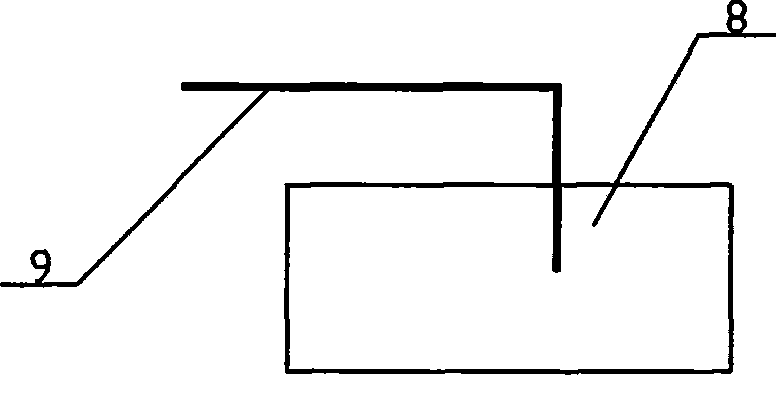

[0040] The step of thermocouple installation is to install the thermocouple on the cathode carbon block first, and the thermocouple is placed in the pre-drilled hole on the cathode carbon block, such as image 3 A hole with a diameter of 4 to 12 mm is drilled on the inner lining of the cathode carbon block shown, and the thermocouple is inserted into the cathode carbon block to a depth of 15 to 20 mm. figure 2 The shown thermocouples are arranged at three positions on both sides and the middle of the length direction of the cathode carbon block, and each position is provided with three thermocouples in the wid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com