Real solid wood reinforced composite solid wood floor and manufacturing method thereof

A solid wood floor, real technology, applied in the direction of manufacturing tools, impregnated wood, wood impregnation, etc., can solve the problem of low wear resistance of UV paint surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

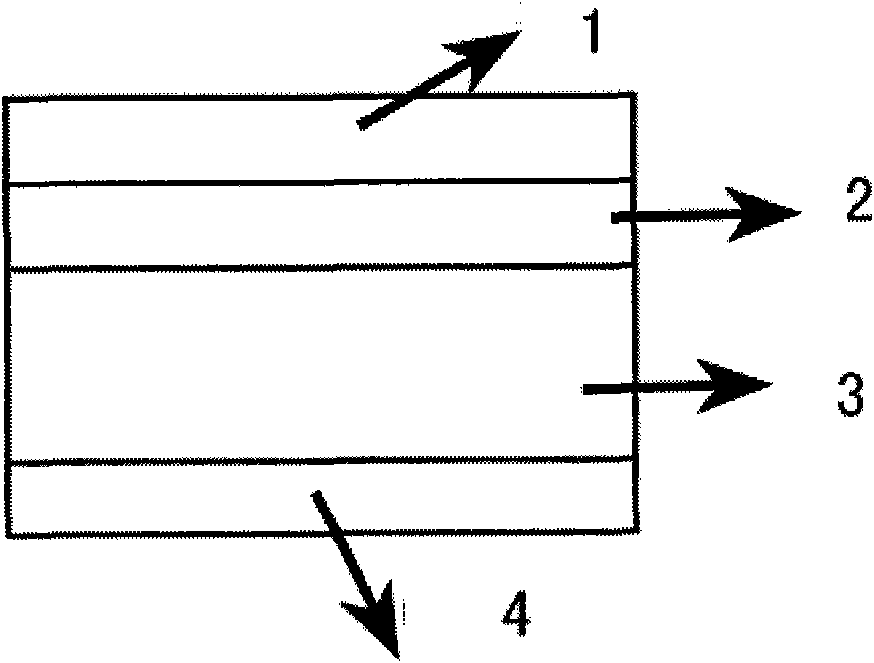

[0019] Referring to FIG. 1 , a real wood reinforced composite solid wood floor includes a wear-resistant layer 1 , a floor surface layer 2 , a substrate layer 3 and a balance layer 4 .

[0020] Wear-resistant layer 1: It is an aluminum oxide film, and the wear-resistant surface of aluminum oxide reaches (about 10 grams to about 100 grams) and the size of each sheet is about (2.48 meters × 1.26 meters). It can also be painted on the wear-resistant surface of aluminum oxide after dipping.

[0021] Floor surface layer 2: a solid wood layer with a thickness of about 0.06 mm to 5 mm, or parquet veneer, or spliced veneer (commonly known as: technical veneer), or a combination of veneer and printed wood grain paper, or veneer produced by other processes.

[0022] Substrate layer 3: The thickness is about 3 mm to 68 mm, including melamine wood fiber substrate, or single-layer solid wood substrate, or a substrate that is mixed and laminated with solid wood substrate and wood fiber su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com