Complex revolving body contour measuring method and device capable of eliminating part positioning error

A positioning error and contour measurement technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of inability to eliminate the inclination error of the central axis and the theoretical axis, low work efficiency, long adjustment time, etc., and achieve easy programming Automatic execution, time-saving installation, and easy control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

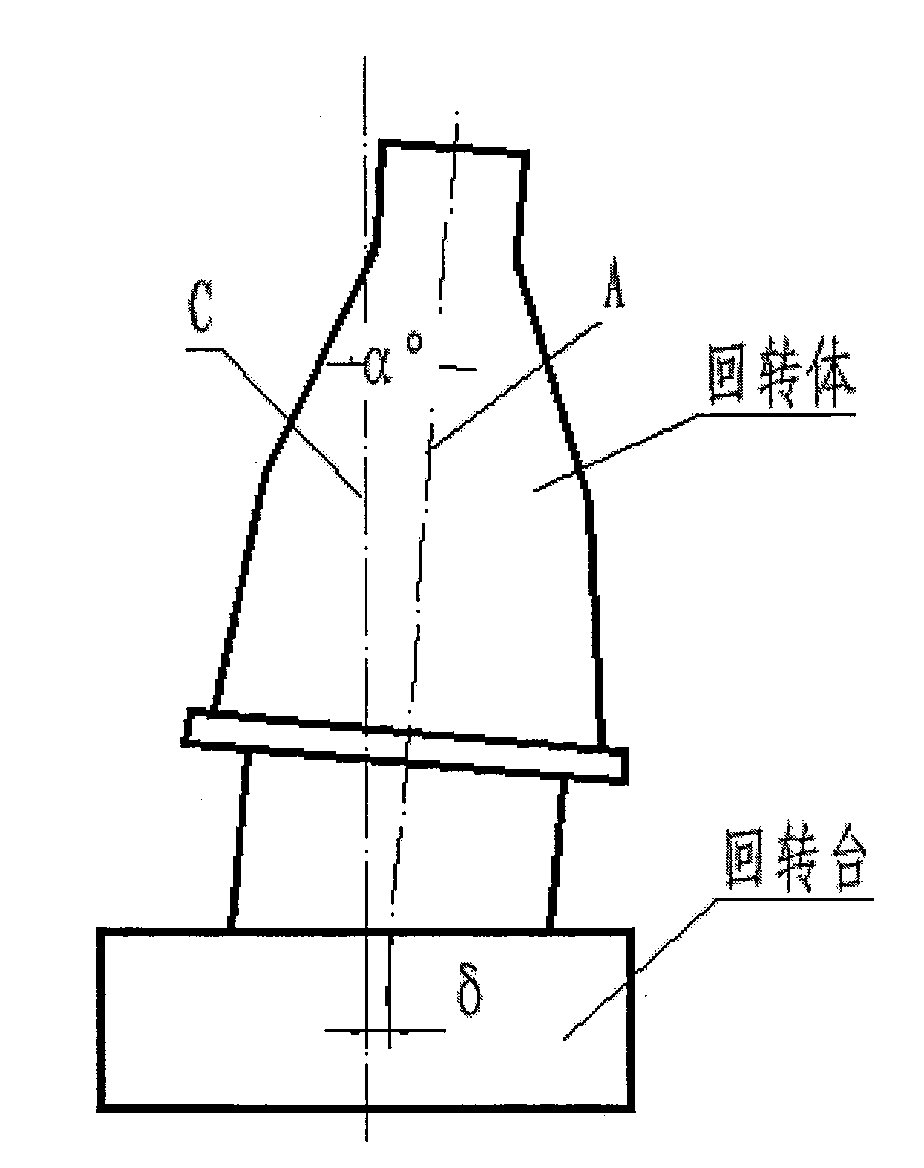

[0032] The method and device for measuring the profile of a rotating body that can eliminate part positioning errors are described in detail as follows in combination with the embodiments and accompanying drawings:

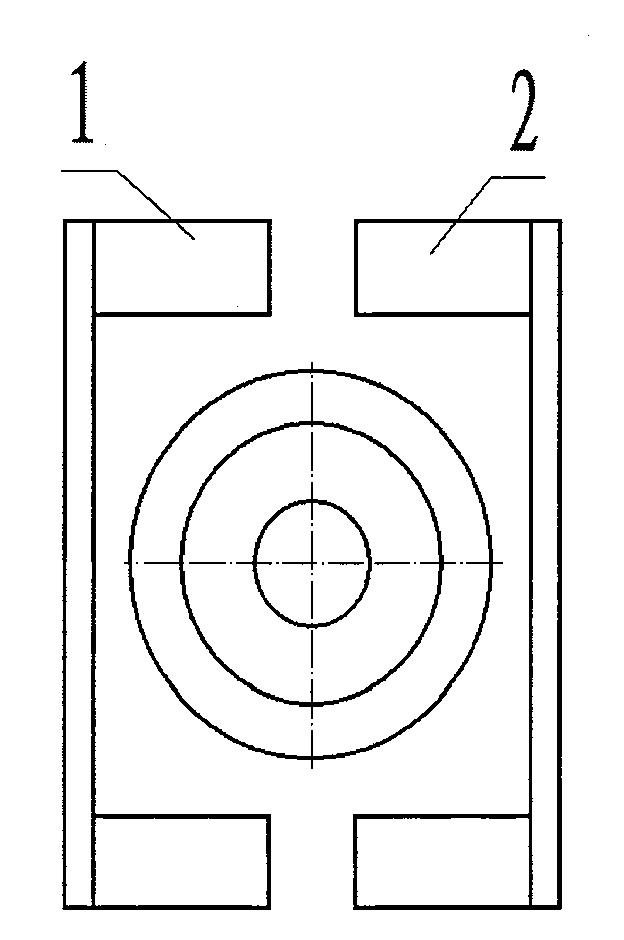

[0033] see Figure 5 , the tested part 3 is placed on the rotary table, the rotary table 4 is installed on the instrument base 5 and connected with the instrument main shaft 9, the instrument main shaft 9 and the shaft sleeve 10 constitute a precision rotary shaft system; the first measuring head 1 and the second measuring head 2 are installed on the same height of the vertical guide rail system composed of the guide rail floating frame 8 and the vertical guide rail 6, and the first measuring head 1 and the second measuring head 2 are arranged radially on both sides of the measured object 3 Symmetrical distribution, can be arranged vertically or horizontally. Before the measurement, first calibrate the distance between the measuring heads, and make the two measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com