Casing device of metallized film capacitor assembling machine

A technology of metallized film and sleeve device, applied in film/thick film capacitors, capacitors, capacitor manufacturing and other directions, can solve the problems of affecting the quality of capacitors, different lengths of catheters, low efficiency, etc. The effect of high degree and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

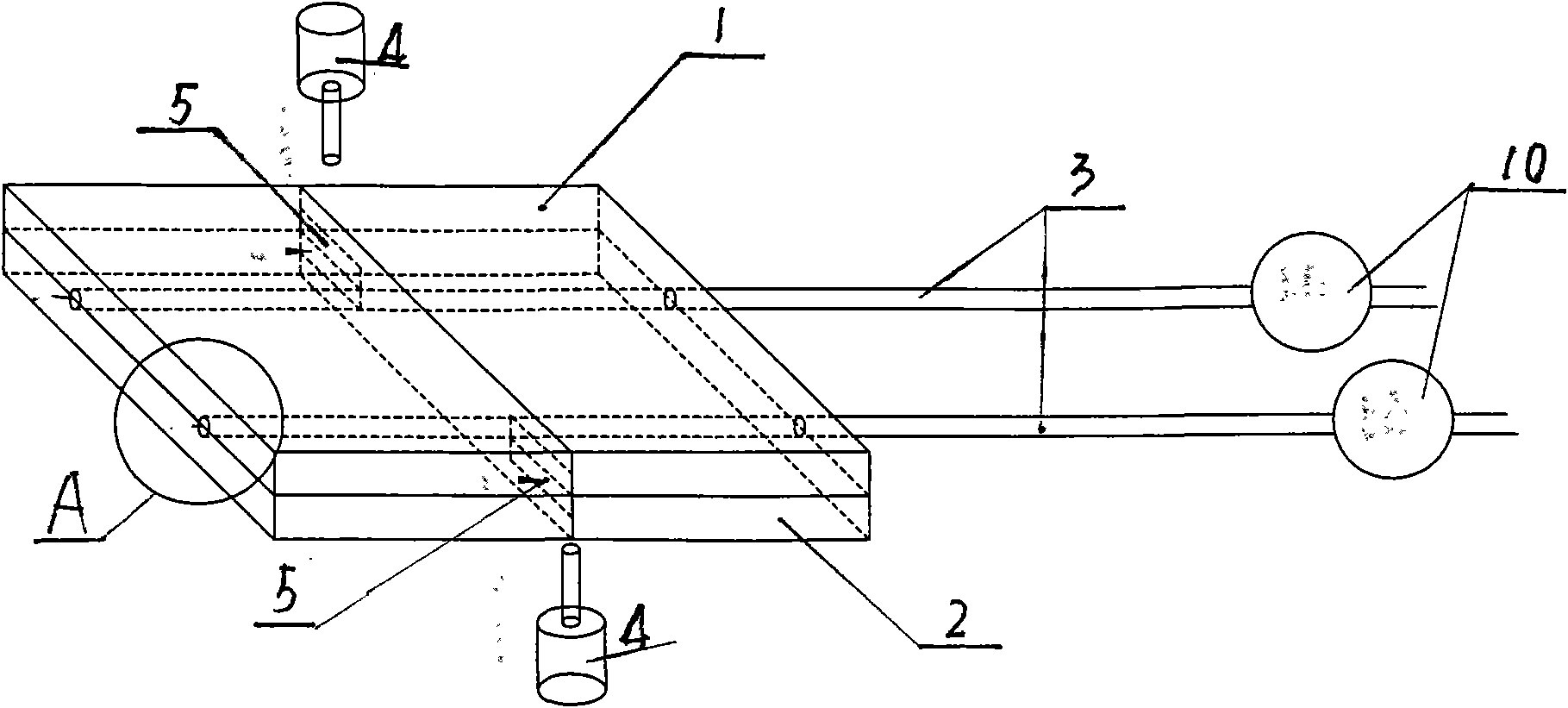

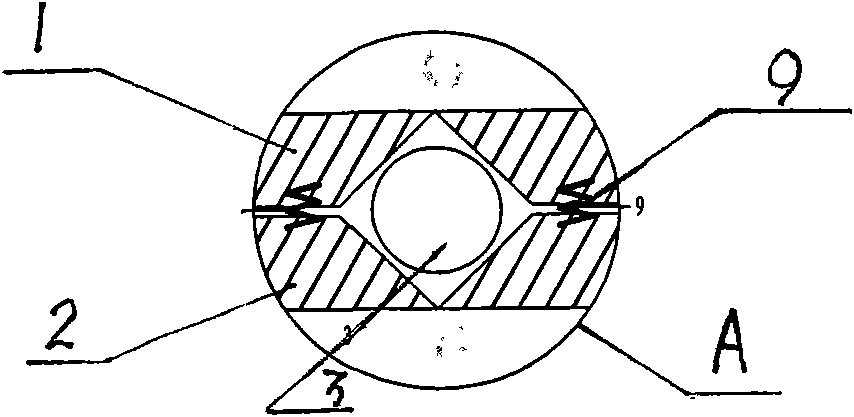

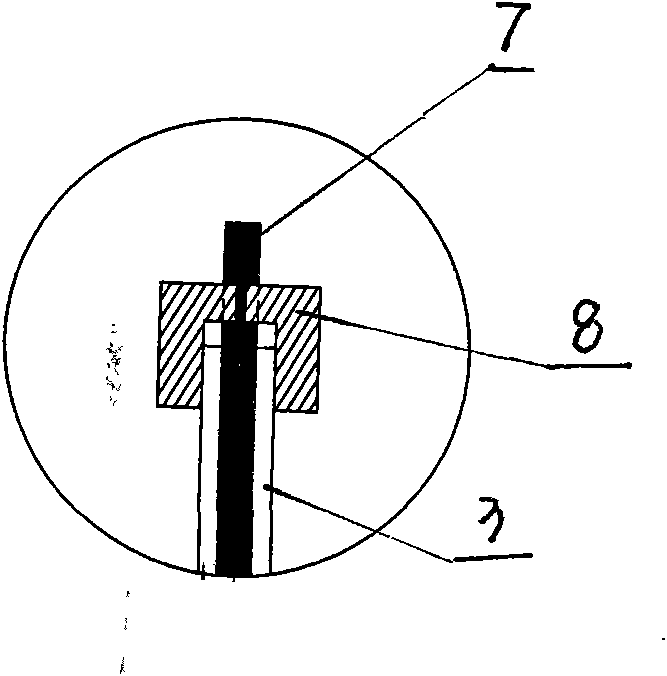

[0010] exist figure 1 Among them, there is an upper splint 1 and a lower splint 2, and there are V-shaped grooves on the opposite surfaces of the upper and lower splints 1 and 2, and a compression spring 9 and a blade 5 are installed, and the upper splint 1 and the lower splint 2 are respectively fixed with Cylinder 4, the piston movement of cylinder 4 can compress the upper and lower splints 1 and 2, and the inner diameter of the inner cavity formed by the V-shaped grooves of the upper and lower splints is smaller than the outer diameter of the casing when they are pressed, which is an interference fit; the upper and lower splints When the V-shaped grooves of the splints 1 and 2 are loosened, the inner diameter of the cavity formed is larger than the outer diameter of the casing 3, which is a clearance fit; the upper and lower splints 1 and 2 pressed by the cylinder 4 drive the catheter to the element CP through the V-shaped grooves. The wire 7 moves, a part of the length of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com