Automatic blank feeding device of full-automatic plastic drawing-blowing machine

A stretch-blow machine, fully automatic technology, applied in the field of plastic machinery, can solve problems such as complex structure of motion mechanism and control device, troublesome processing, installation and maintenance, etc., and achieve the effects of high work efficiency, time saving and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

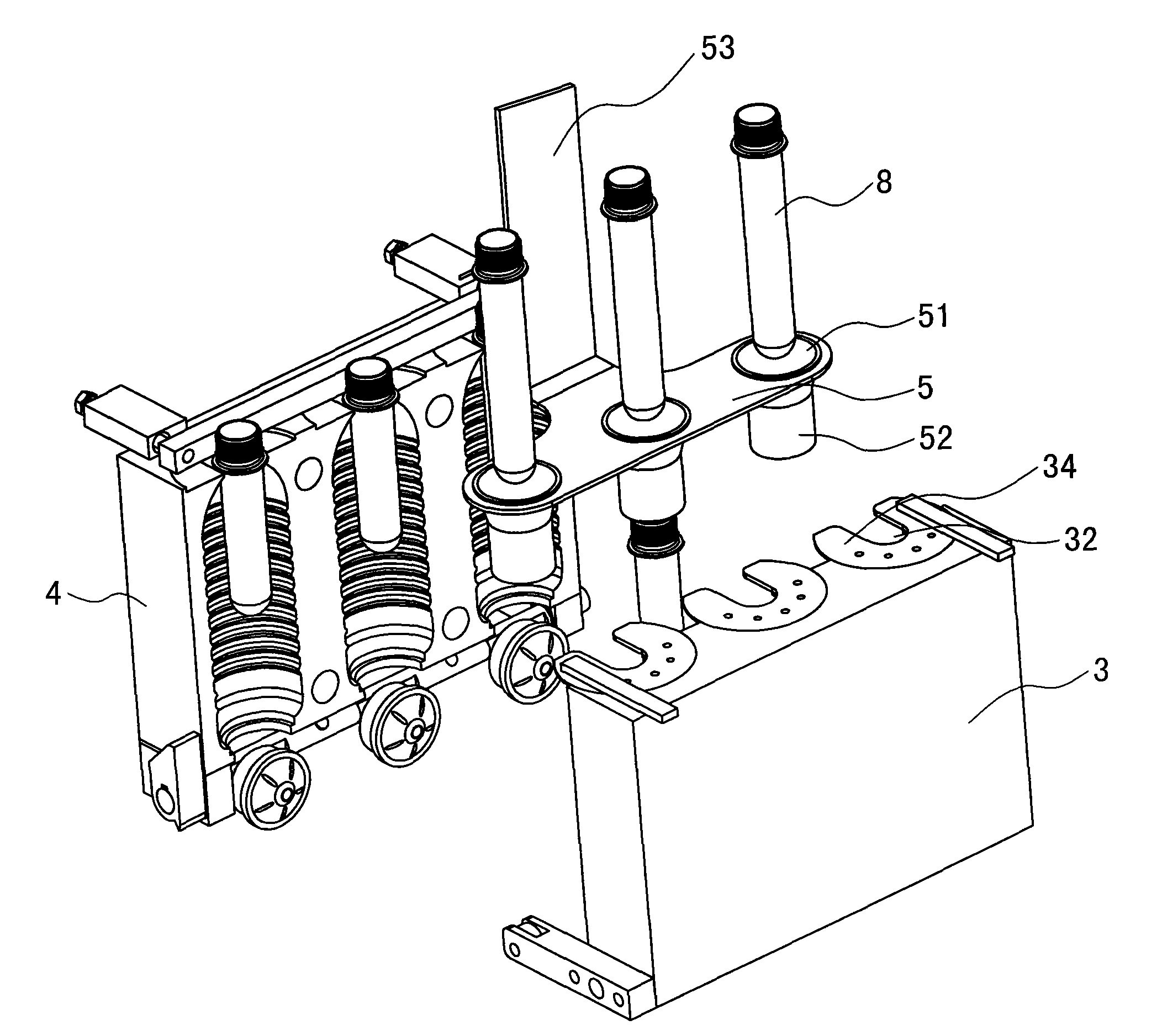

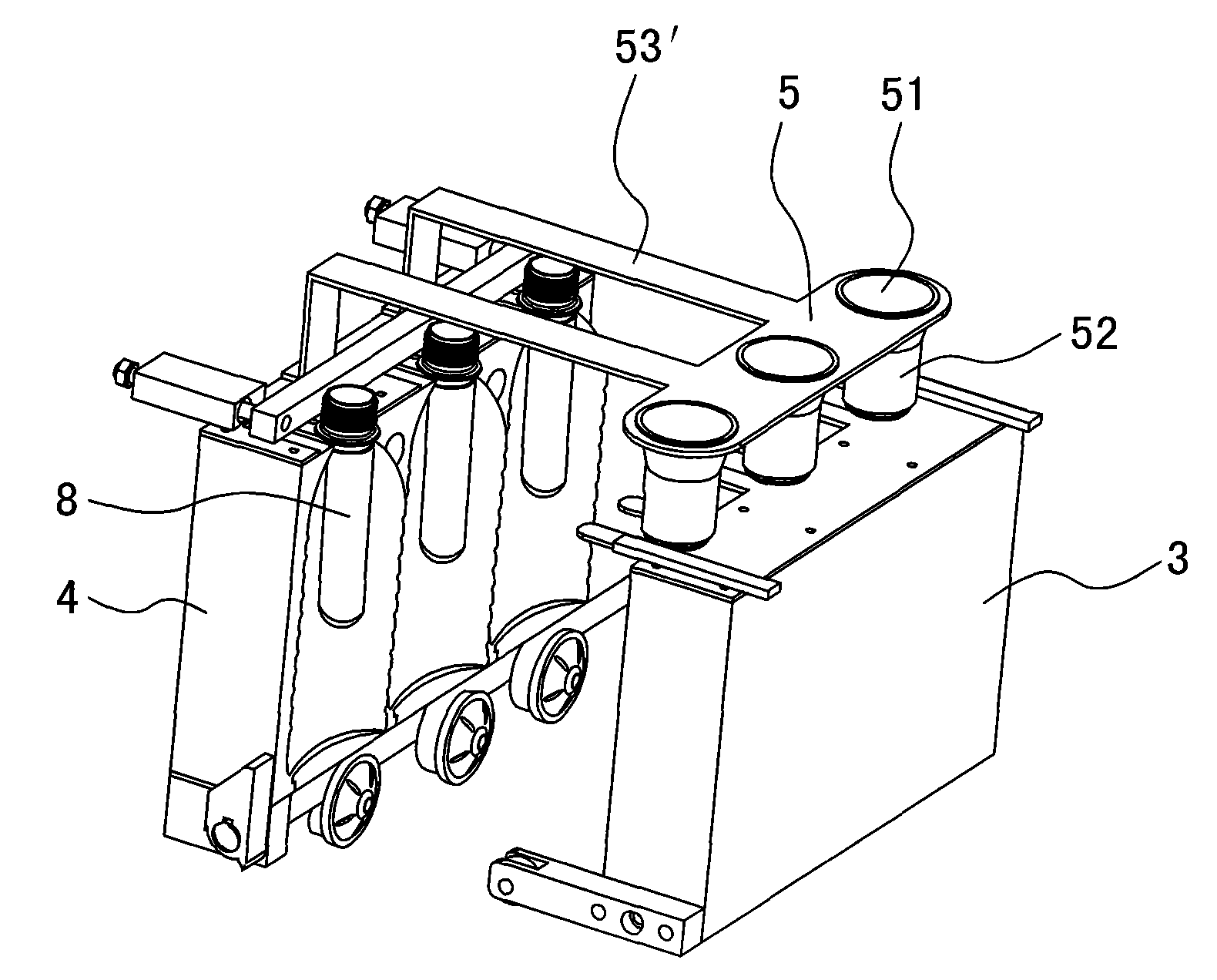

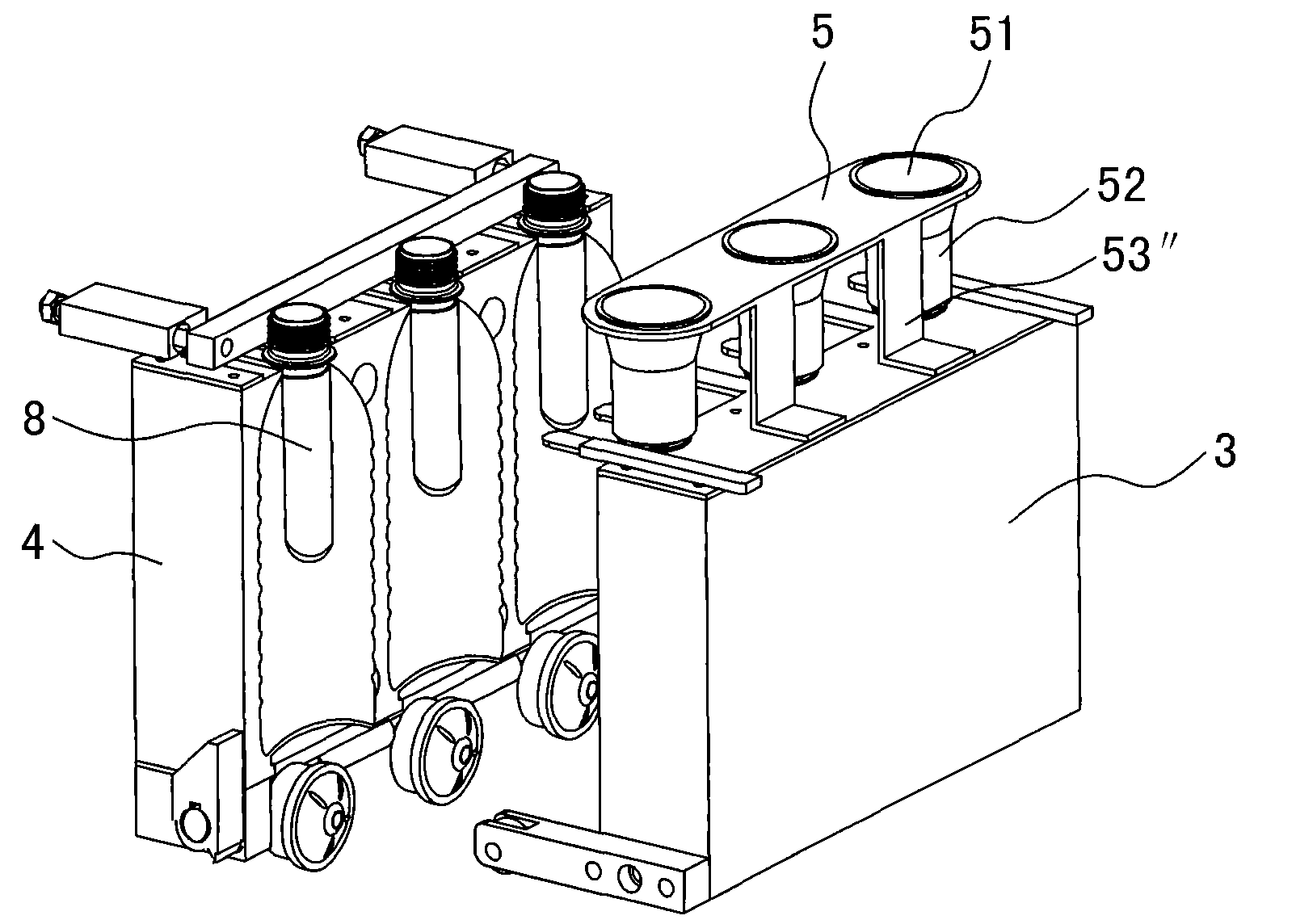

[0010] The invention relates to an automatic blanking device for a fully automatic plastic stretch blowing machine, such as Figure 1-Figure 3 As shown, it includes a frame, a template installed on the frame and a mold opening and closing mechanism, and a heating device and a bottle blank conveying mechanism. A fixed mold 4 and a movable mold 3 are installed on the template, and it is characterized in that the mold is equipped with an upper Blank device, the described upper blank device includes the supporting plate 5 that is installed on the frame or the mould, and the plastic bottle blank guiding cylinder 52 is installed in the supporting plate, and the center of the guiding cylinder and the center of the mold are on a straight line, and the movable mold 3 die mouth Connect base fork 34 is installed on 32, connect base fork and plastic bottle base 8 contact. During work, the heated preform is driven to the top of the guide cylinder 52 by the preform conveying mechanism (the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com