Heading machine provided with cantilever type front canopy supporting protection device

A technology of a support device and a forward probe beam, which is applied in the field of roadheaders with a cantilever type forward probe beam support device, can solve the problems of long implementation time, low safety factor, and high labor intensity of the temporary support device, and achieves shortened time. Effects of temporary support time, reduced labor intensity, and high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

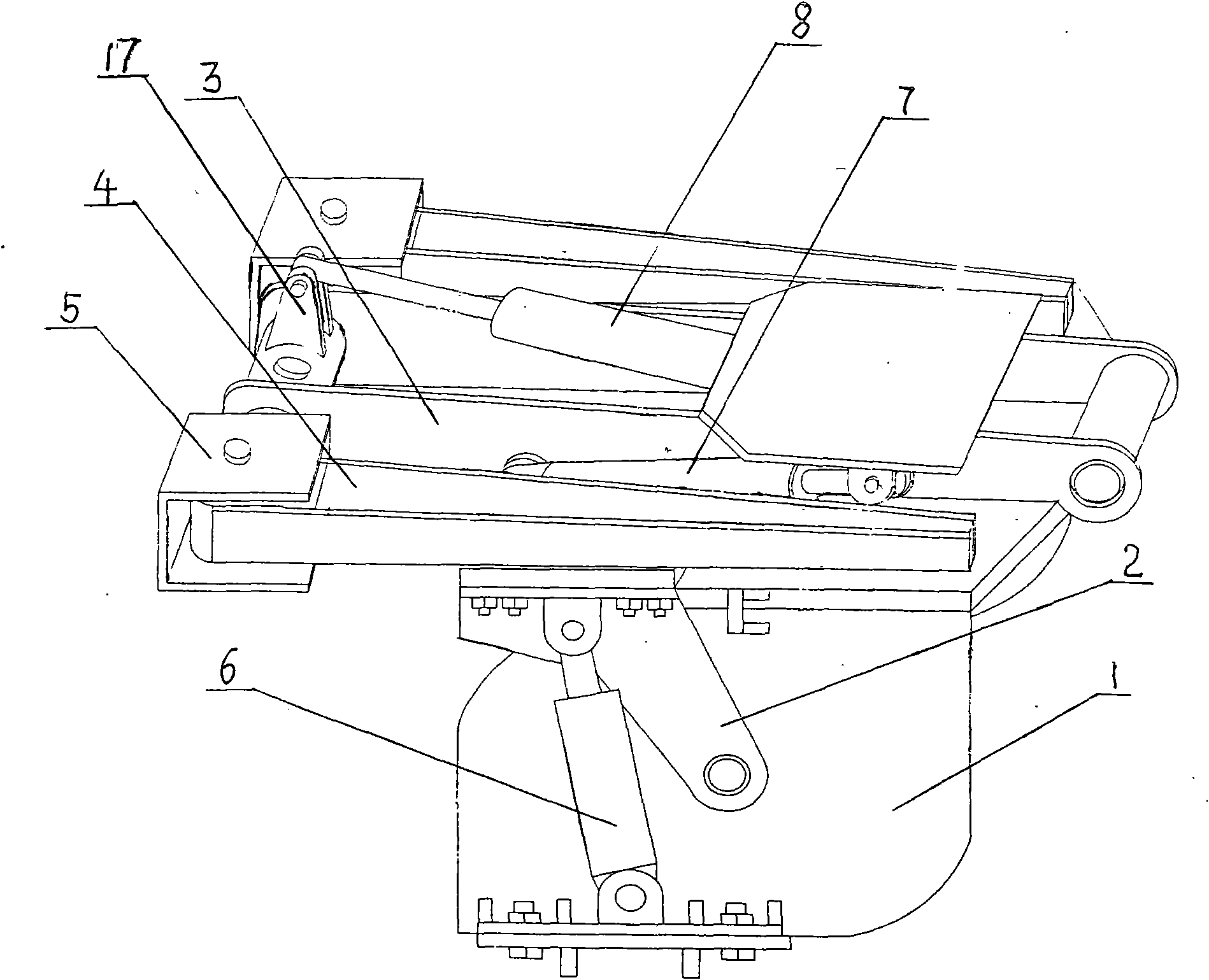

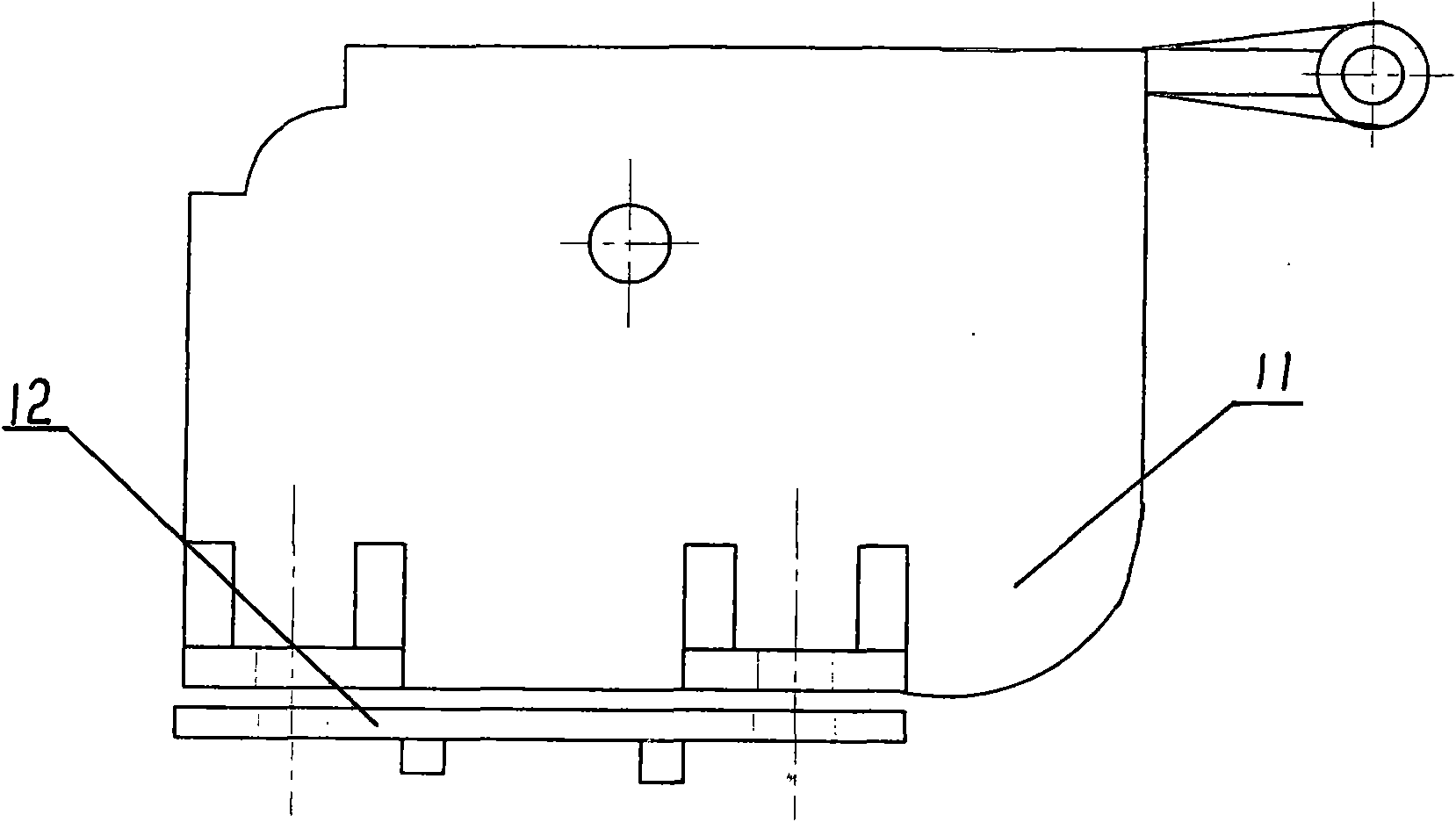

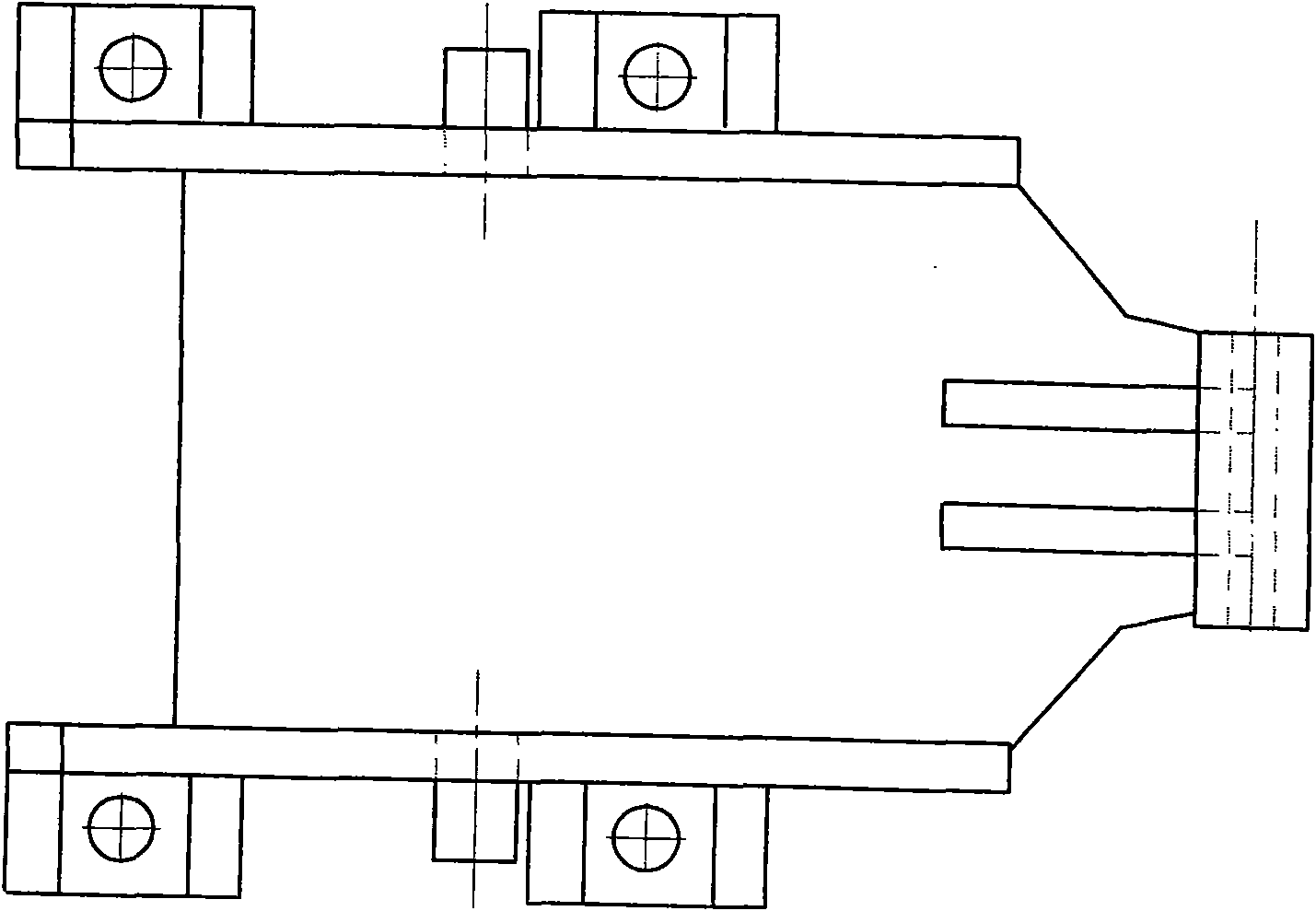

[0021] A roadheader with a cantilever-type front beam support device, including a front cantilever and a deceleration device located on the front cantilever. The frame 2 is composed of a support plate and two support legs fixed below the support plate. The two support legs of the telescopic frame 2 are hinged to both sides of the probe base 1. The front end of the upper surface of the probe base 1 is hinged with a rotating beam 3. The other end of the beam 3 is pierced with a rotating shaft 10 perpendicular to it, and both ends of the rotating shaft 10 are fixed with a joist base 5, a groove is opened on the joist base 5 and a joist 4 is hinged in the groove, and the beam base 1 is two A telescopic frame jack 6 is hinged between the side bottom and the supporting legs of the telescopic frame 2, and a rotary beam jack 7 respectively positioned at both sides of the rotary beam 3 is hinged between the support plate of the telescopic frame 2 and the rotating beam 3. A joist jack 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com