Pneumatic tire

A technology for pneumatic tires and treads, applied to tire parts, tires, wheels, etc., can solve problems such as insufficient countermeasures, and achieve the effect of preventing sharp decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

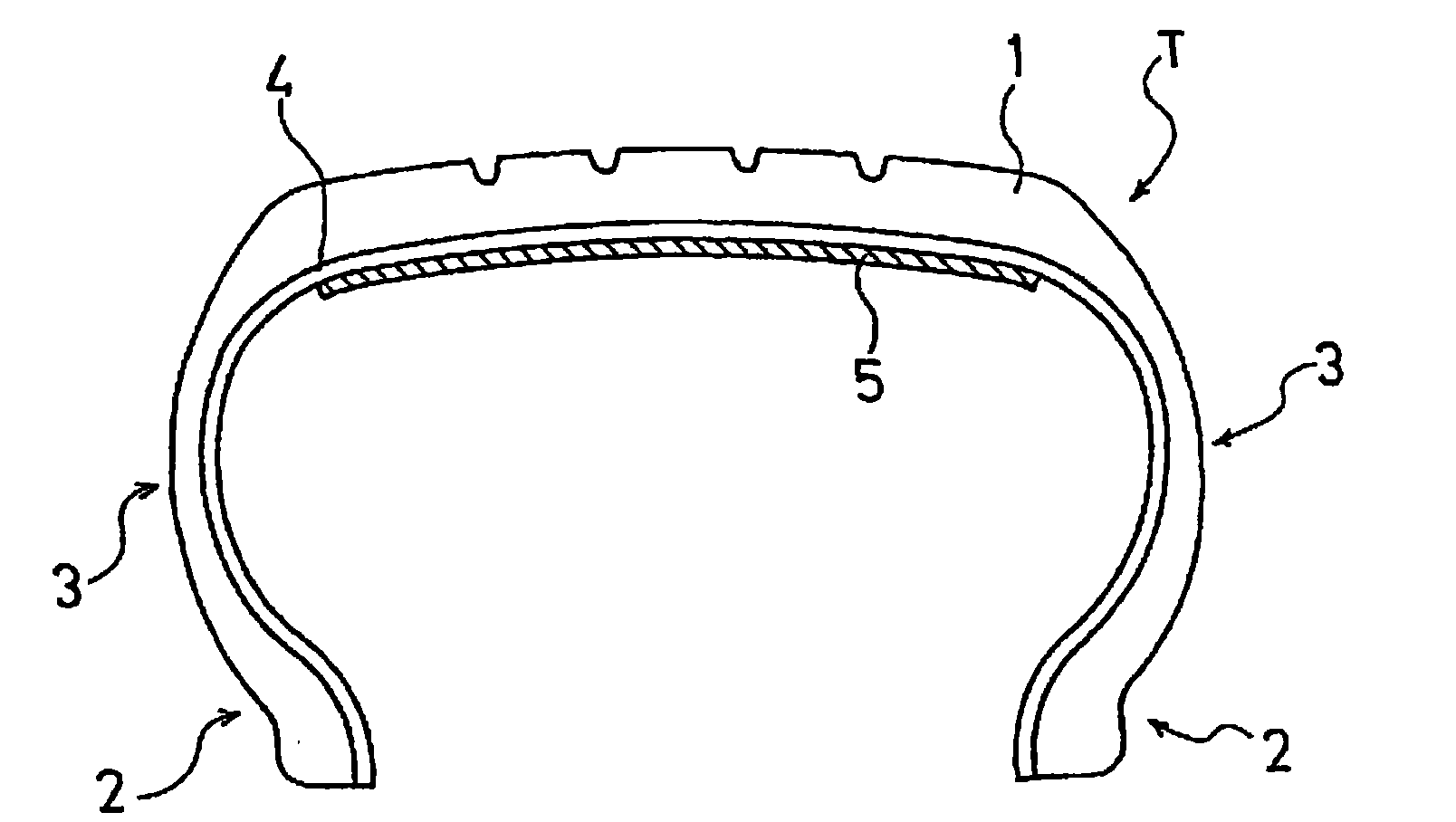

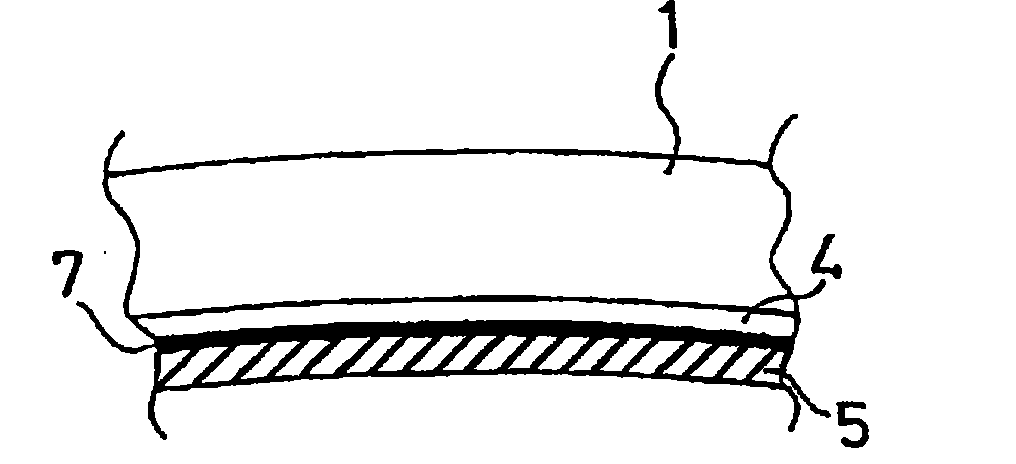

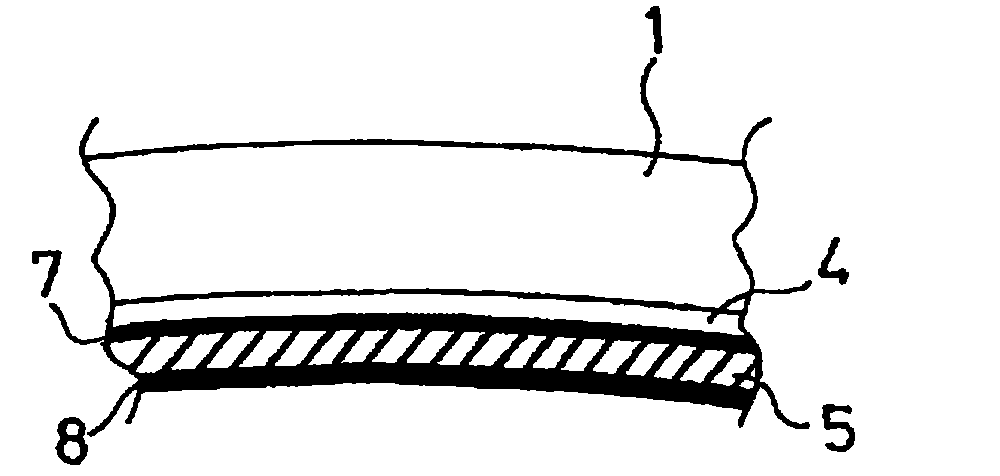

[0044] Set tire size to 205 / 65R15 and tire construction to figure 1 With the structures shown, a conventional tire (corresponding to Example 1 in JP-A-2003-183623 ) and a tire of the present invention using an adhesive sealant as the puncture prevention layer were manufactured. In addition, in each tire, the thickness of the puncture prevention layer was set to 5 mm, and as the gel sheet of the tire of the present invention, a gel sheet mainly composed of ethylene-styrene copolymer (penetration: 60 , Oscar C-type hardness: 15, compression permanent strain rate 8%).

[0045] After assembling each tire on the rim, fill it with an air pressure of 210kPa, and run it continuously at a speed of 90km / h for 8 hours through an indoor roller testing machine, and then investigate the left and right ends of the puncture prevention layer on the inner surface of the tire after running. Offset (movement) condition.

[0046] As a result, in the conventional tire, the width of the puncture p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com