Method for producing aluminum pot

A production method and aluminum pot technology, applied in metal processing equipment, stripping devices, manufacturing tools, etc., can solve the problems of high manufacturing energy consumption, waste of energy, and low yield, and achieve flexible and convenient use, improve production efficiency, and reduce The effect of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

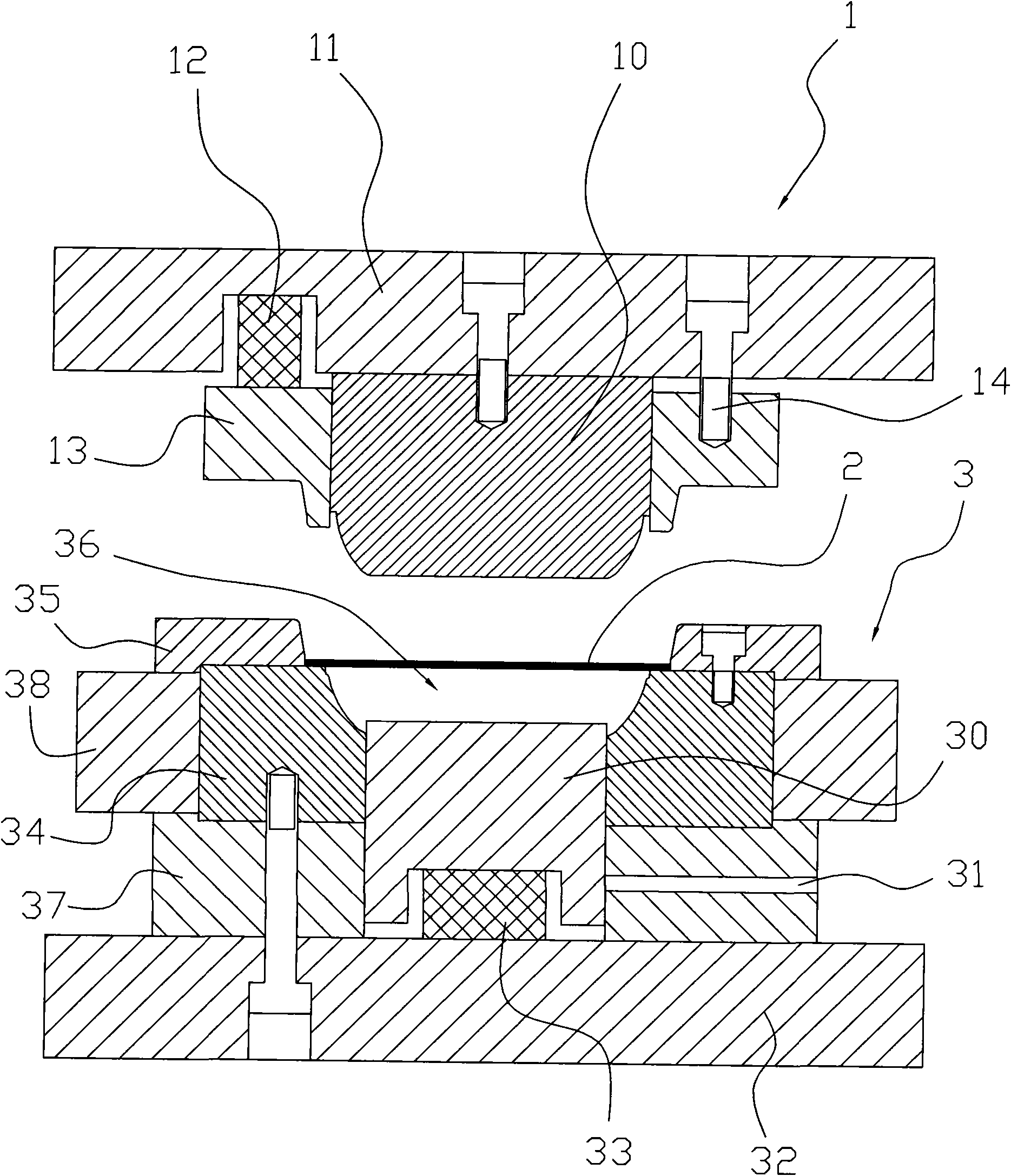

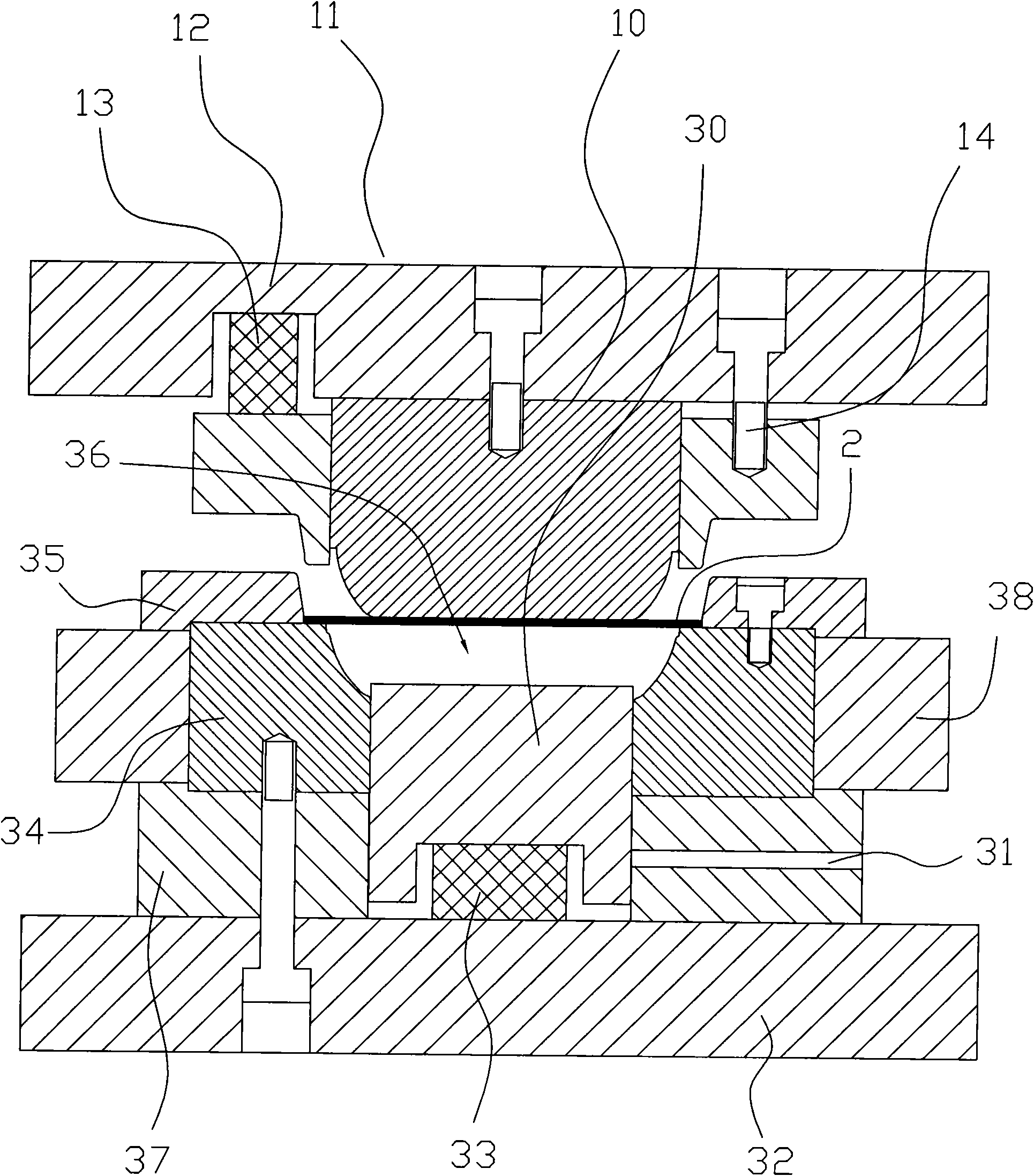

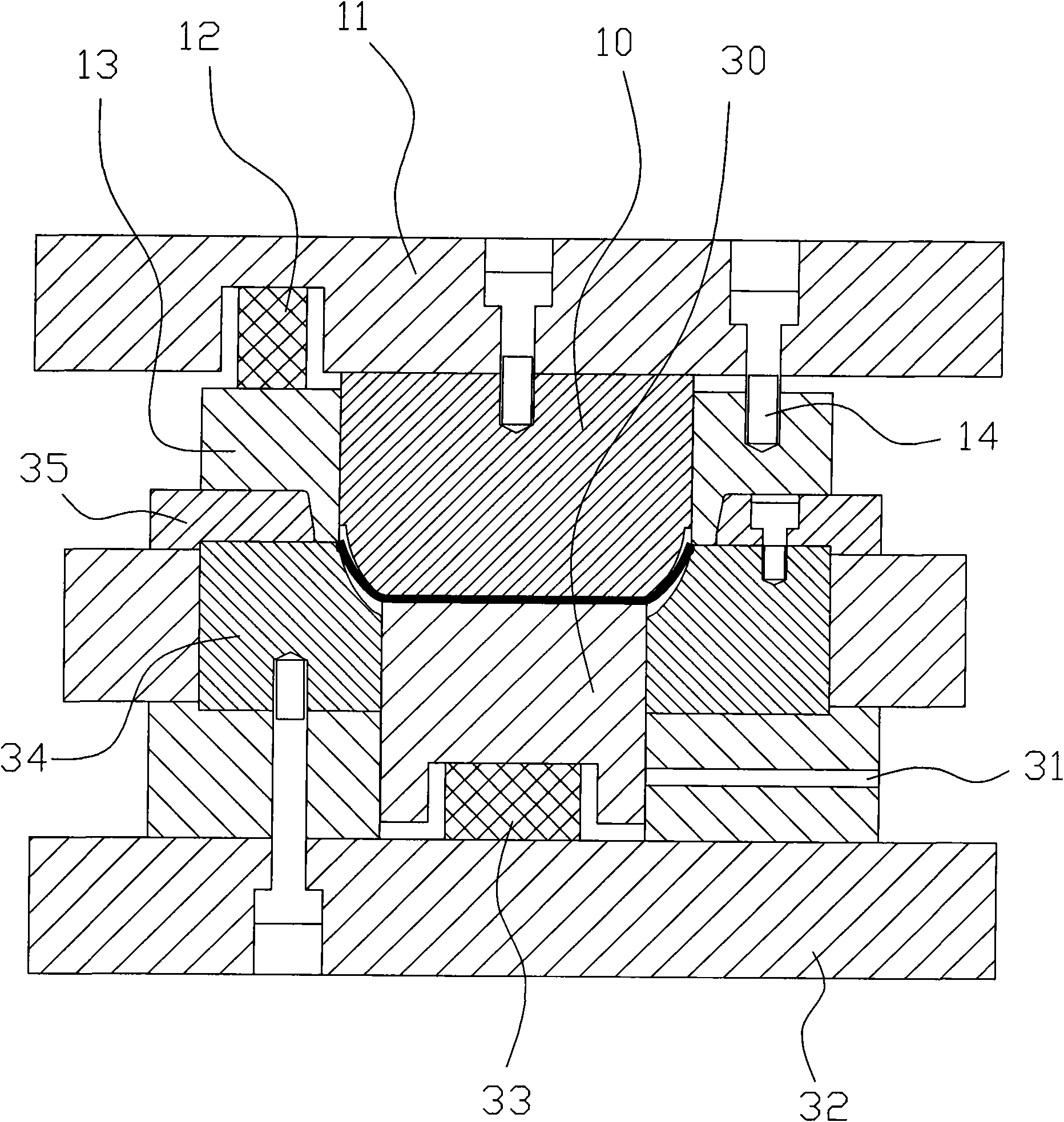

[0021] Such as Figure 1 to Figure 7 As shown, the production method of the aluminum pan of the present embodiment comprises the following steps successively:

[0022] Material selection, take an aluminum sheet 2 with a thickness of 2 to 7 mm, and cut it into an aluminum sheet 2 of the required size for later use;

[0023] Stretch, open the upper mold 1 and the lower mold 3, place the spare aluminum sheet in the limit ring 35 on the periphery of the opening of the die 34 in the lower mold 3, then open the upper mold 1, and press the upper mold 1 , when the punch 10 in the upper die 1 contacts the aluminum sheet 2, continue to press down to stretch the aluminum sheet 2, and when the punch 10 is pressed down, the aluminum sheet 2 and the pusher that can move up and down at the bottom of the die 34 When the block 30 contacts, at least 95% of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com