High-precision Z-axis carrier platform of picosecond laser process equipment

A processing equipment, picosecond laser technology, used in laser welding equipment, metal processing equipment, welding equipment and other directions, can solve the problem of not meeting the lifting accuracy requirements of picosecond laser fine processing equipment, achieve excellent functions, low manufacturing costs, Design novel effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

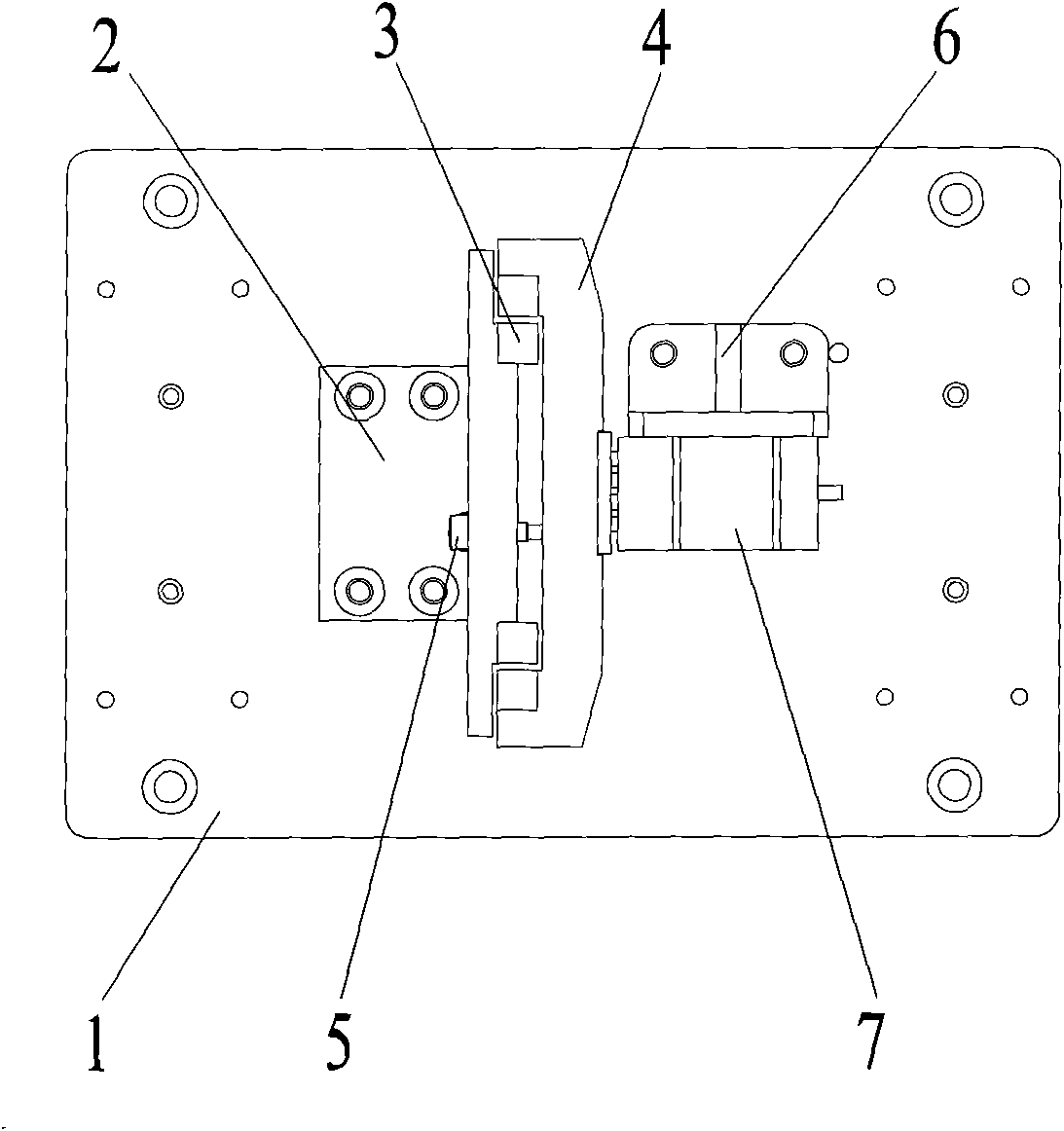

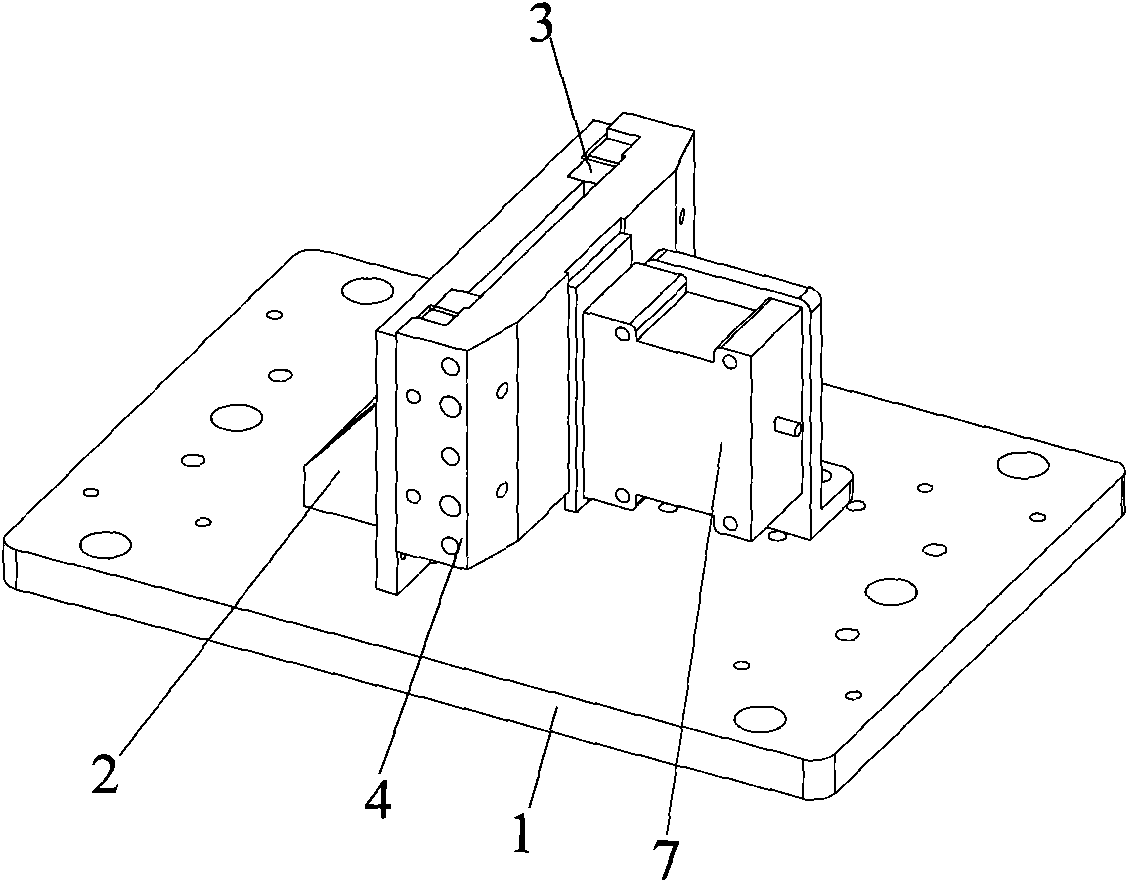

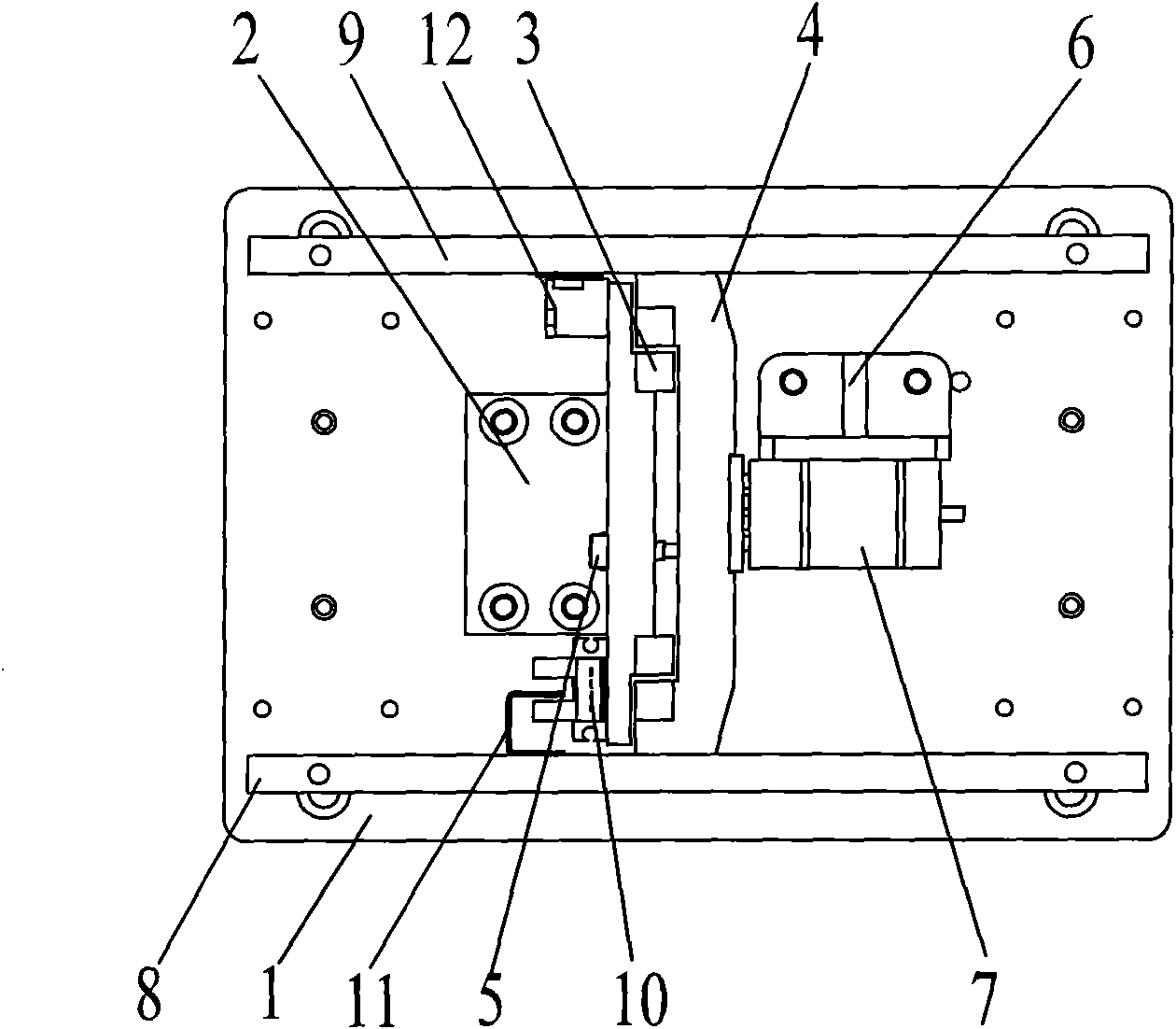

[0024] High-precision Z-axis loading platform for picosecond laser processing equipment, such as Figure 1a , Figure 1b , the Z platform bottom plate 1 is the basic component, the Z fixed plate 2 is fixed on the Z platform bottom plate 1, the Z fixed plate 2 has an L-shaped structure, including a horizontal plane and a vertical plane, and the horizontal plane of the Z fixed plate 2 is fixed to the Z platform bottom plate 1 Connect, install vertical guide rail 3 on the vertical surface of Z fixed plate 2, install a lifting plate 4 that can move up and down along guide rail 3 on the guide rail 3, be used to control the piezoelectric ceramic motor 7 that lift plate 4 moves up and down through motor installation The plate 6 is fixed on the bottom plate 1 of the Z platform. The motor mounting plate 6 has an L-shaped structure, including a horizontal plane and a vertical plane. The piezoelectric ceramic motor 7 has a ceramic sheet attached to the lifting plate 4. When the piezoelec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com