Storage device for binding wire of a cording machine

A technology of accumulating device and strapping device, applied in the field of accumulating device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

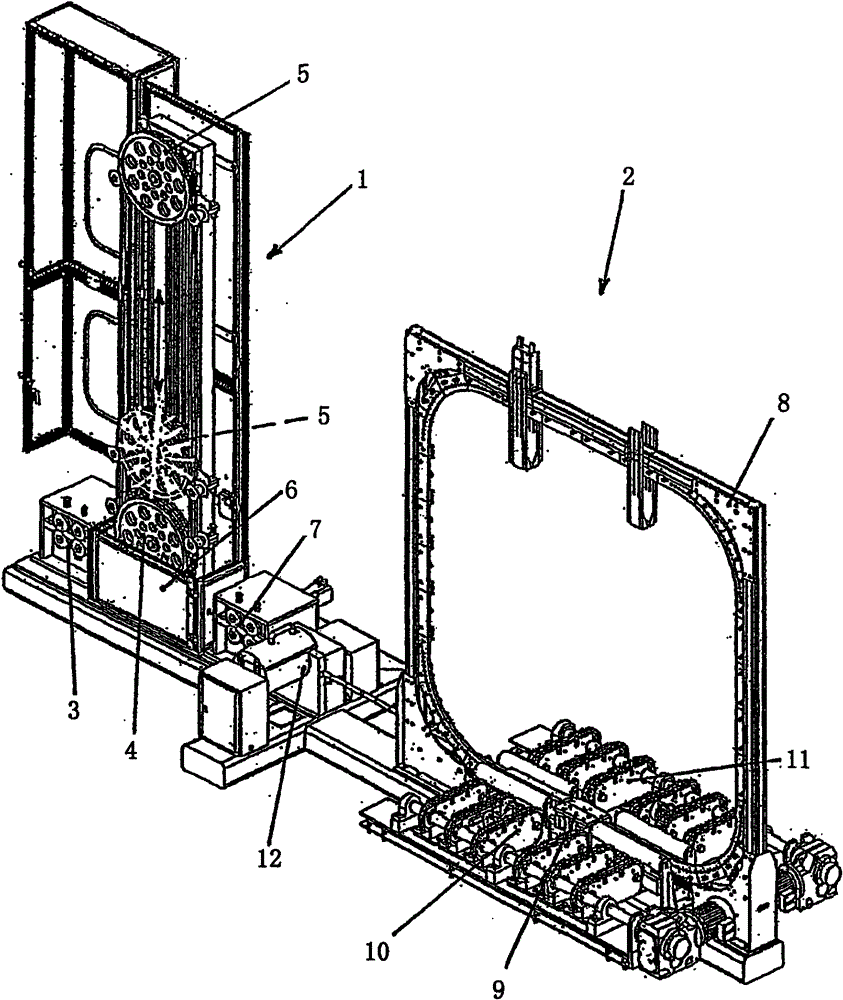

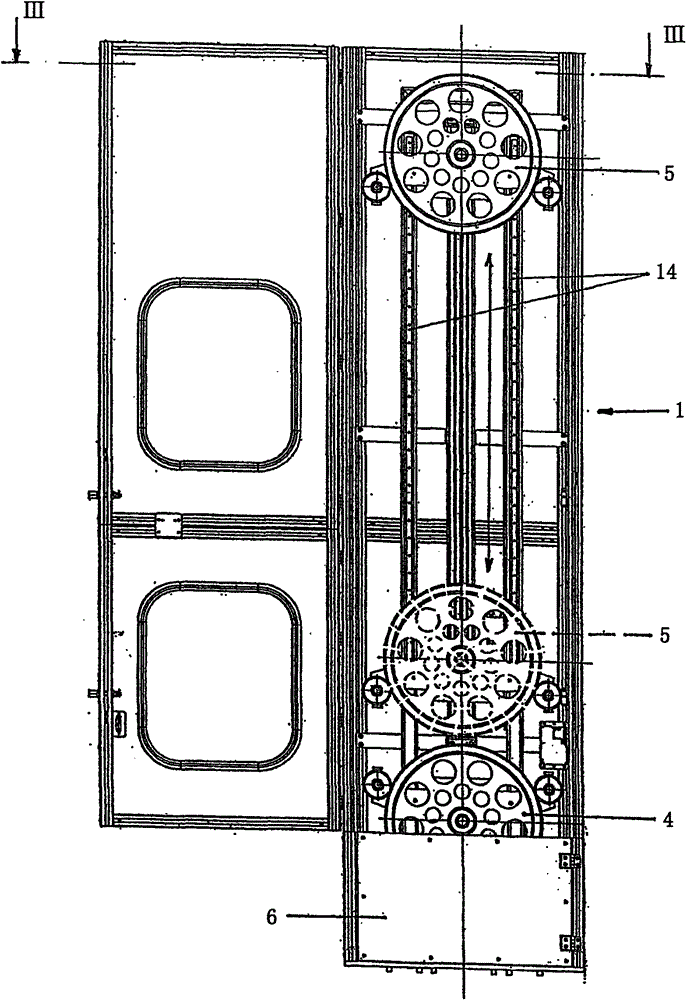

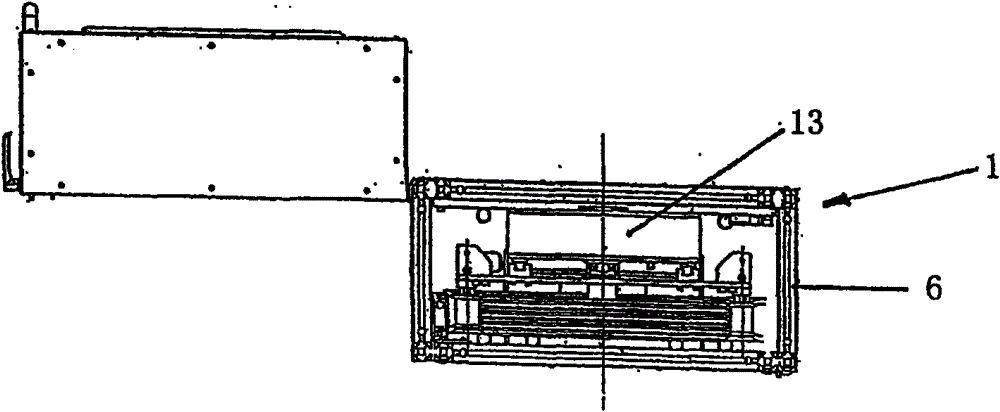

[0043] figure 1 A binding machine for binding pulp bales with galvanized steel wires is shown, which mainly includes an accumulating device 1 and a binding device 2 . The binding wires for binding the pulp bales are supplied to the left side from a drum, tower or similar device not shown here, by being extracted from the rollers with the first drive 3 to the Figure 1-3 The accumulation device of the first embodiment shown in . The binding wire, not shown in the figure, is then wound several times (three times in this embodiment) around the two roller sets 4 , 5 , after which the second drive 7 feeds the binding wire to the binding frame 8 . The roller sets 4, 5 each comprise circular discs arranged coaxially close to each other, which can pivot independently of each other and which have grooves in their circumferential surfaces to guide the binding wire.

[0044]In the binding frame 8, the binding wire is wound once in an anti-clockwise direction at an angle of slightly mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com