Aluminum alloy rod peeling and scrap breaking device

An aluminum alloy rod and adjusting device technology, which is applied to metal processing equipment, metal processing mechanical parts, maintenance and safety accessories, etc., can solve the problems of high work intensity, high production cost, and high toughness of aluminum alloy rods, and achieves improved production. Efficiency and product quality, automated production, high chip stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

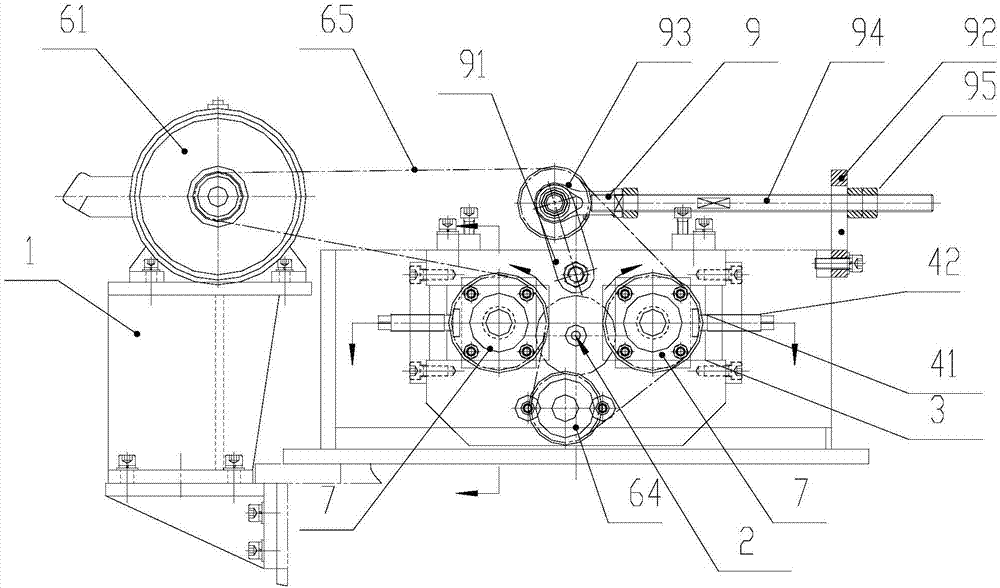

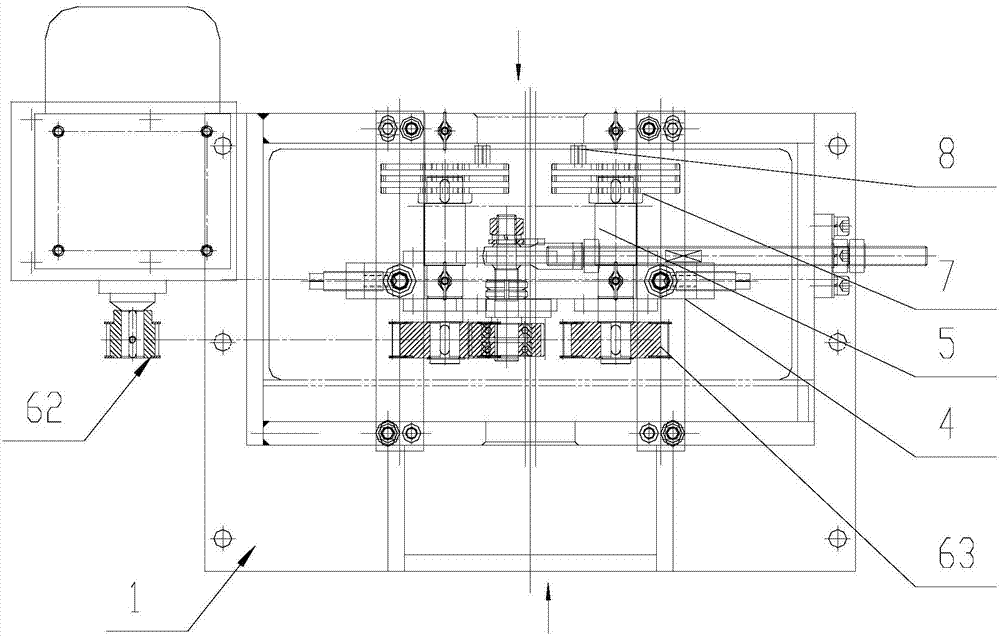

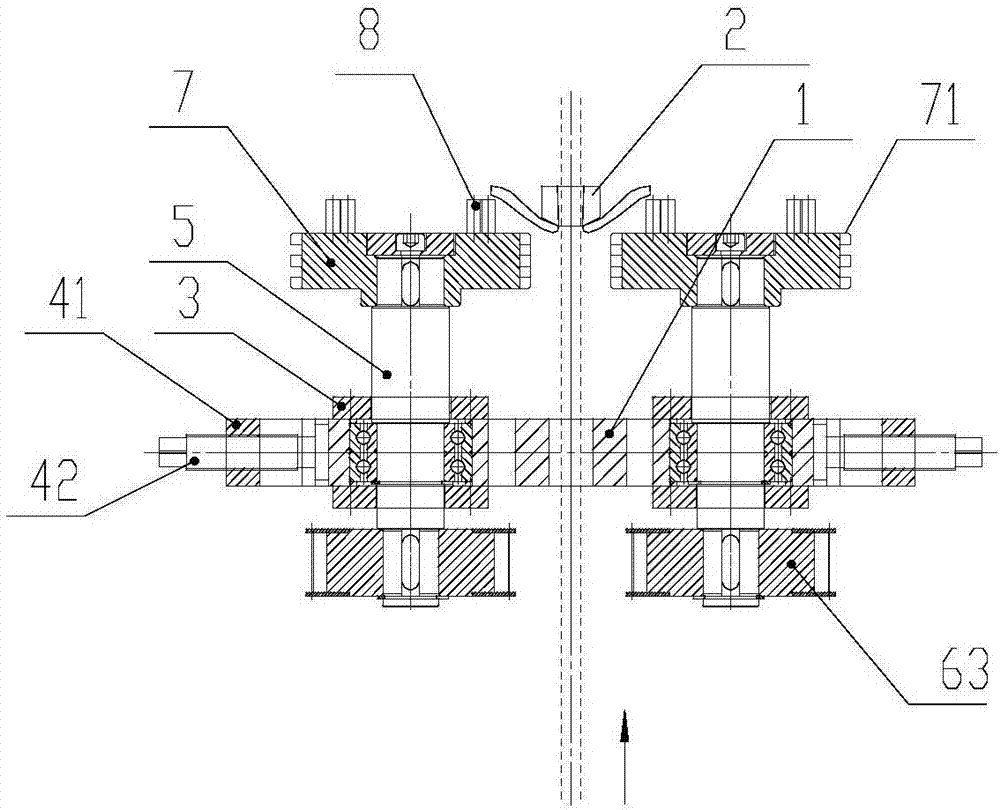

[0018] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0019] Such as Figure 1-3 As shown, a peeling and chipping device for an aluminum alloy rod includes a frame 1, on which a peeling die 2 is arranged, and on the frame 1, a sliding seat 3 is respectively arranged on both sides of the peeling die 2. The two sliding seats 3 are located on the same straight line, and the frame 1 is provided with an adjusting device 4 for adjusting the position of the sliding seats 3 . The adjusting device 4 includes a fixing plate 41 arranged on the frame 1 , an adjusting screw 42 is pierced through the fixing plate 41 , and the end of the adjusting screw 42 is connected with the sliding seat 3 .

[0020] The sliding seat 3 is provided with a rotating shaft 5 arranged parallel to the direction of sending rods, and the frame 1 is provided with a power mechanism 6 for driving the two rotating shafts 5 to rotate in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com