Single-motor two-parallel boring bar boring device with widely adjustable center distance

A single-power, large-scale technology, applied in the direction of boring bar, boring/drilling, boring machine/drilling machine parts, etc., can solve the problems of unfavorable mass production, many processing steps, and low efficiency, so as to improve production efficiency and reduce The effect of production cost and simplification of processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

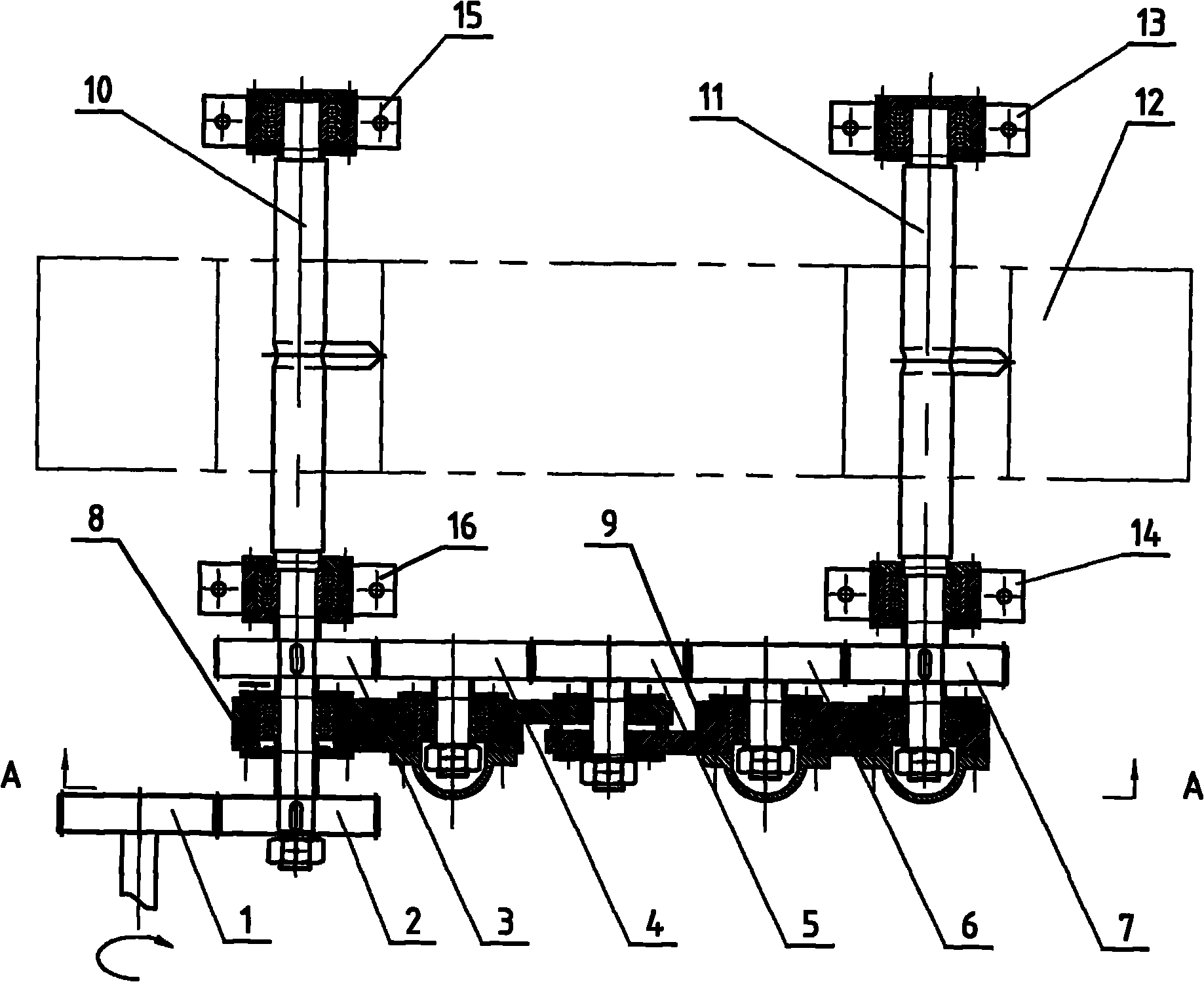

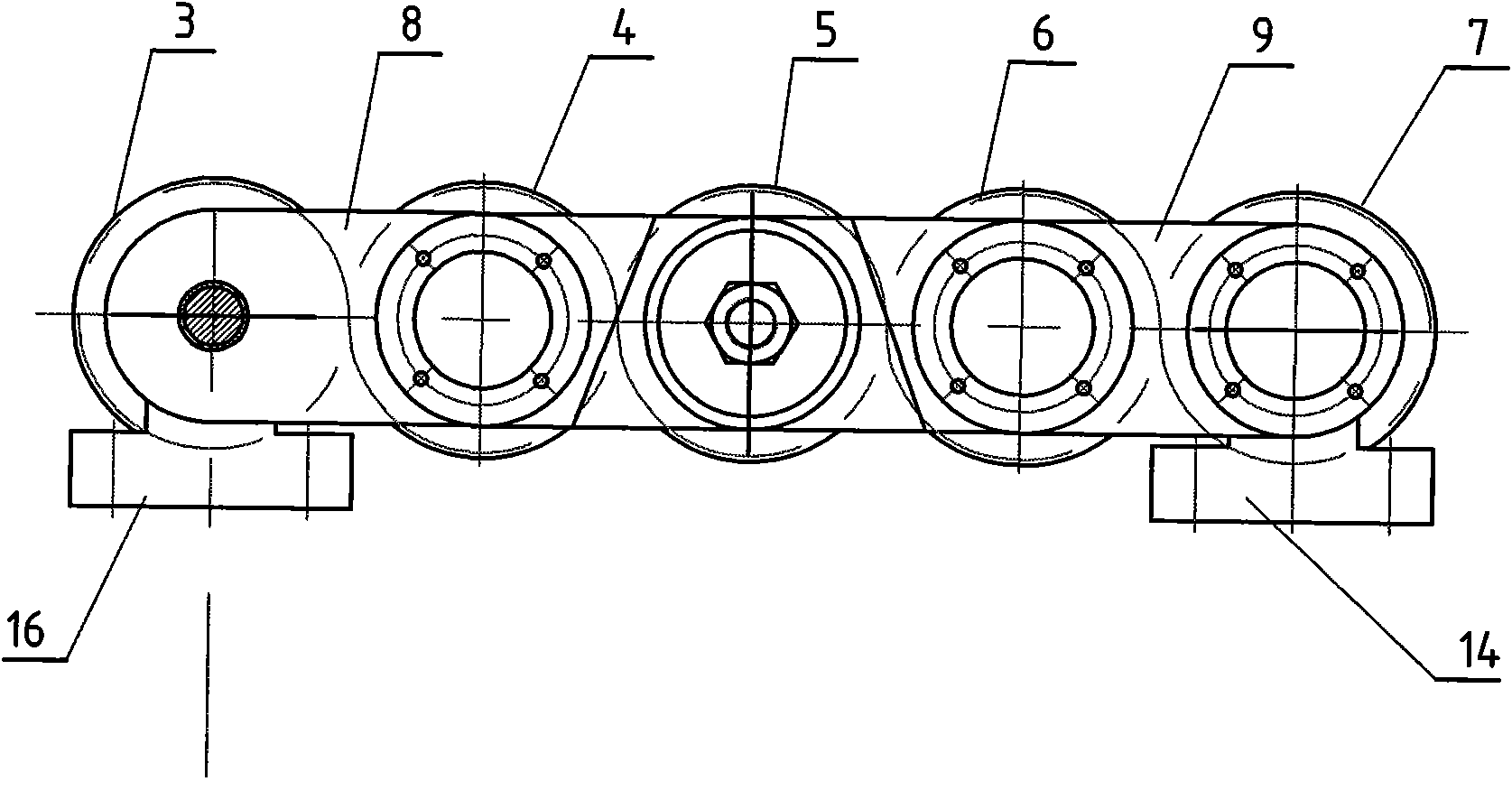

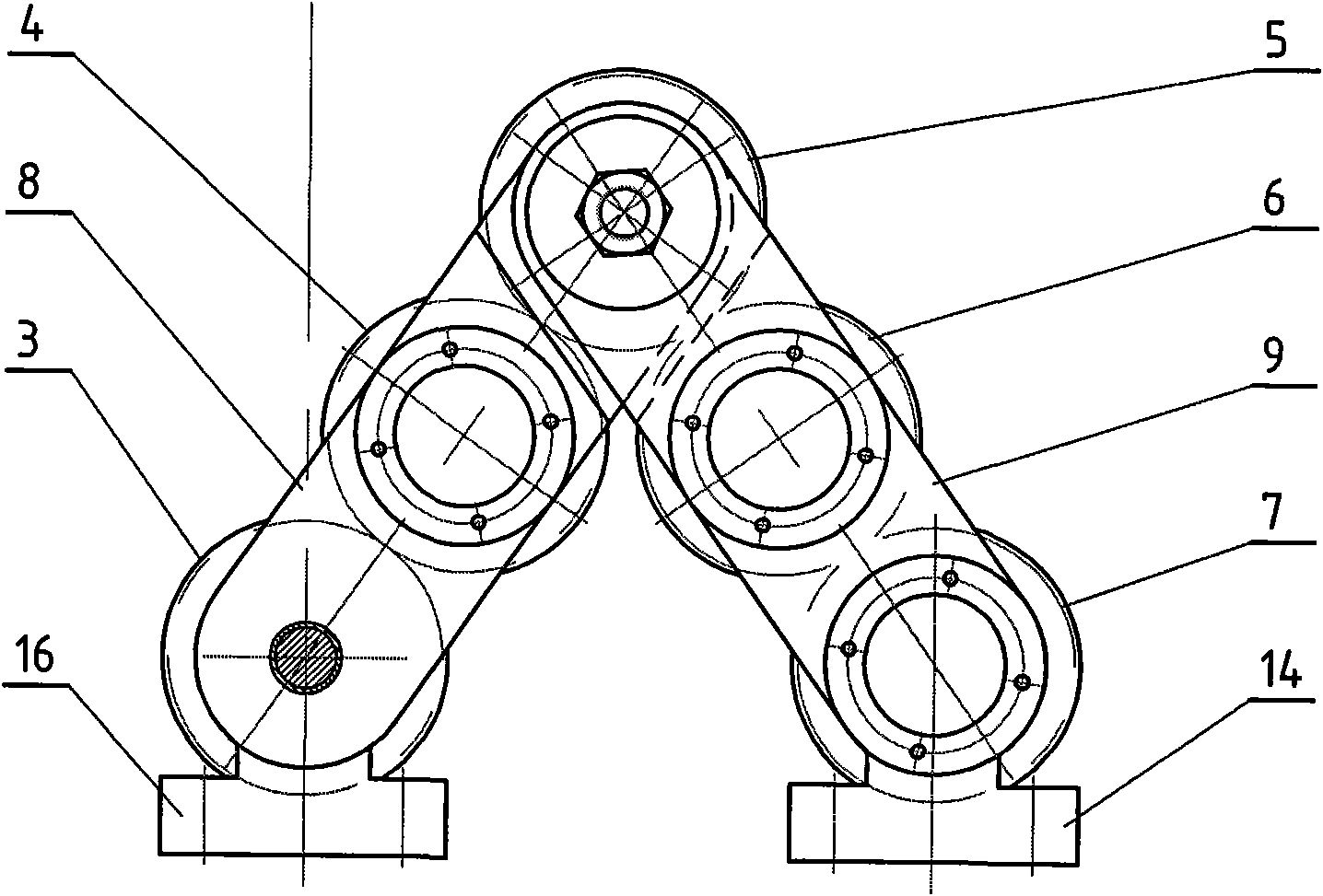

[0014] Example Figure 1-3 Shown: a single-power boring device with two parallel boring bars whose center distance can be greatly adjusted, including a positioning boring bar 10 and a translation boring bar 11; the positioning boring bar 10 is supported on the first rolling bearing seat fastened to the boring machine table 15 and the second rolling bearing housing 16, the translation boring bar 11 is supported on the third rolling bearing housing 13 and the fourth rolling bearing housing 14 capable of translating along the boring machine workbench, ensuring that the translation boring bar 11 is always parallel to the positioning boring bar 10 during translation. On the outer side of the second rolling bearing housing 16 of the positioning boring bar 10, the first boring bar gear 3 is installed with a key connection. On 10, between the transmission gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com