Multicomponent fiber carding machine

A carding machine and multi-component technology, applied in the field of carding machines, can solve the problems of no substantial improvement, large space occupation of equipment, low production efficiency, etc., and achieve good stripping effect, high production efficiency, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

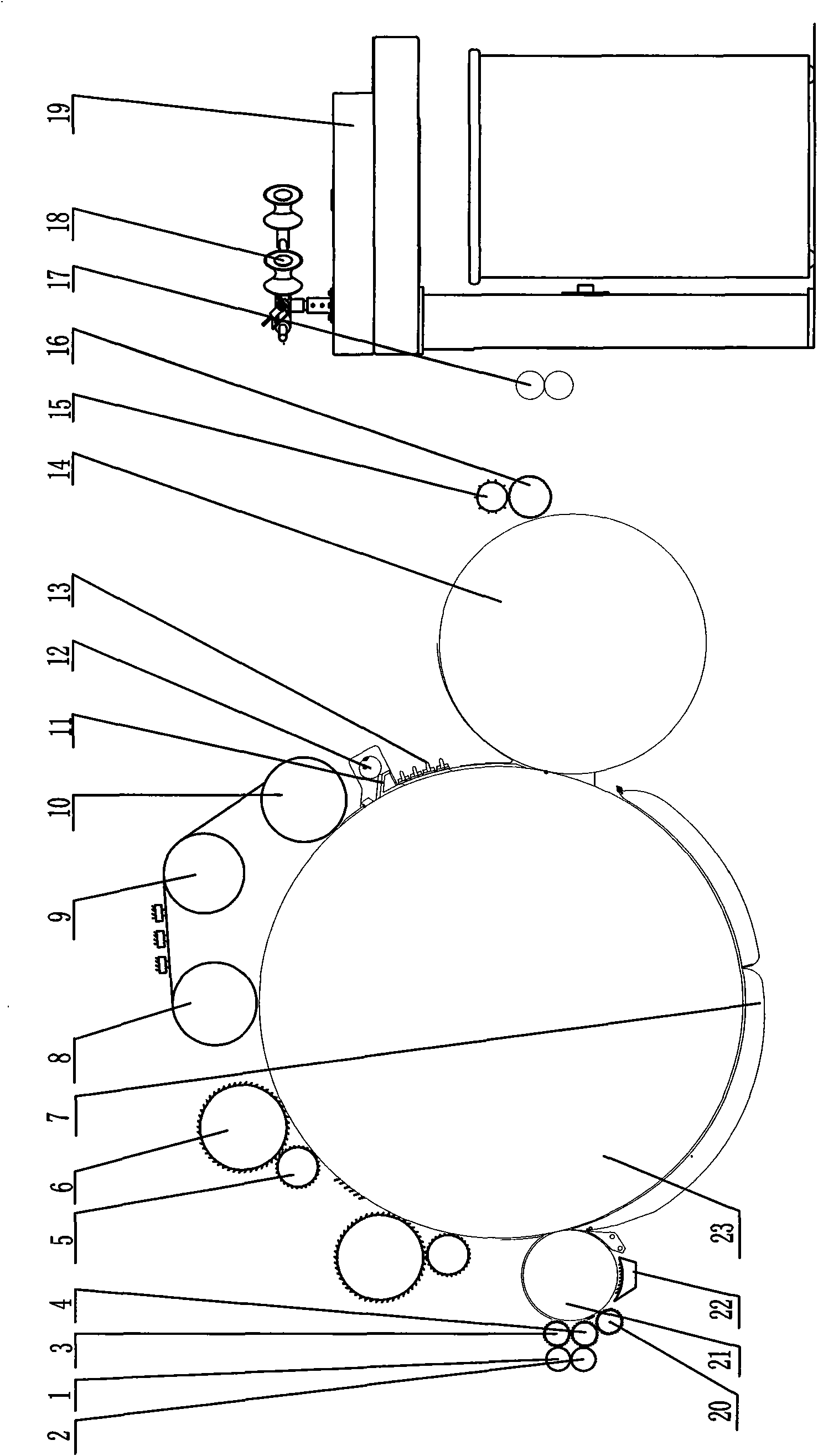

[0014] Referring to the accompanying drawings, a multi-component fiber carding machine includes a feeding mechanism, a carding mechanism, a stripping mechanism and a coiling mechanism. The technical content not mentioned in the present invention can adopt the corresponding or corresponding technical method in the prior art, and the innovation content of the present invention will be mainly explained below.

[0015] The above-mentioned feeding mechanism includes a pair of rear groove rollers, which are composed of an upper rear groove roller 1 and a lower rear groove roller 2, and a pair of front feeding rollers are arranged in front of the rear groove rollers. The front feed roller is made up of the upper front feed roller 3 and the lower front feed roller 4, and a bristle roller 21 is arranged in front of the front feed roller, and the bristle roller 21 is at the rear bottom of the cylinder 23 and the cylinder 23 connection, the brittle roller 21 adopts a comb needle structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com