Large-span concrete slope masonry machine

A concrete and long-span technology, applied in construction, infrastructure engineering, etc., can solve the problems of difficulty in disassembly, affecting the position of feeding and distributing materials, and high cost, so as to achieve continuous and compact feeding and distributing process, and accurate control of the distributing position Smooth, reduce the effect of conveying distance

Active Publication Date: 2011-01-05

河北省水利工程局集团有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the above equipment has problems such as high cost, heavy weight, difficulty in disassembly and assembly across buildings, high cost of use, and large operation and maintenance costs.

At present, the upper and lower unloading vehicles of masonry machines are driven separately, and the upper and lower unloading vehicles are respectively driven by sprockets. Two sets of transmission mechanisms and chain tracks are required. The structure is complex and the manufacturing cost is high. During the forming process, the position of the upper and lower unloading vehicles cannot be accurately controlled, which will affect the position of feeding and distributing materials, and affect the quality of the entire slope masonry

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

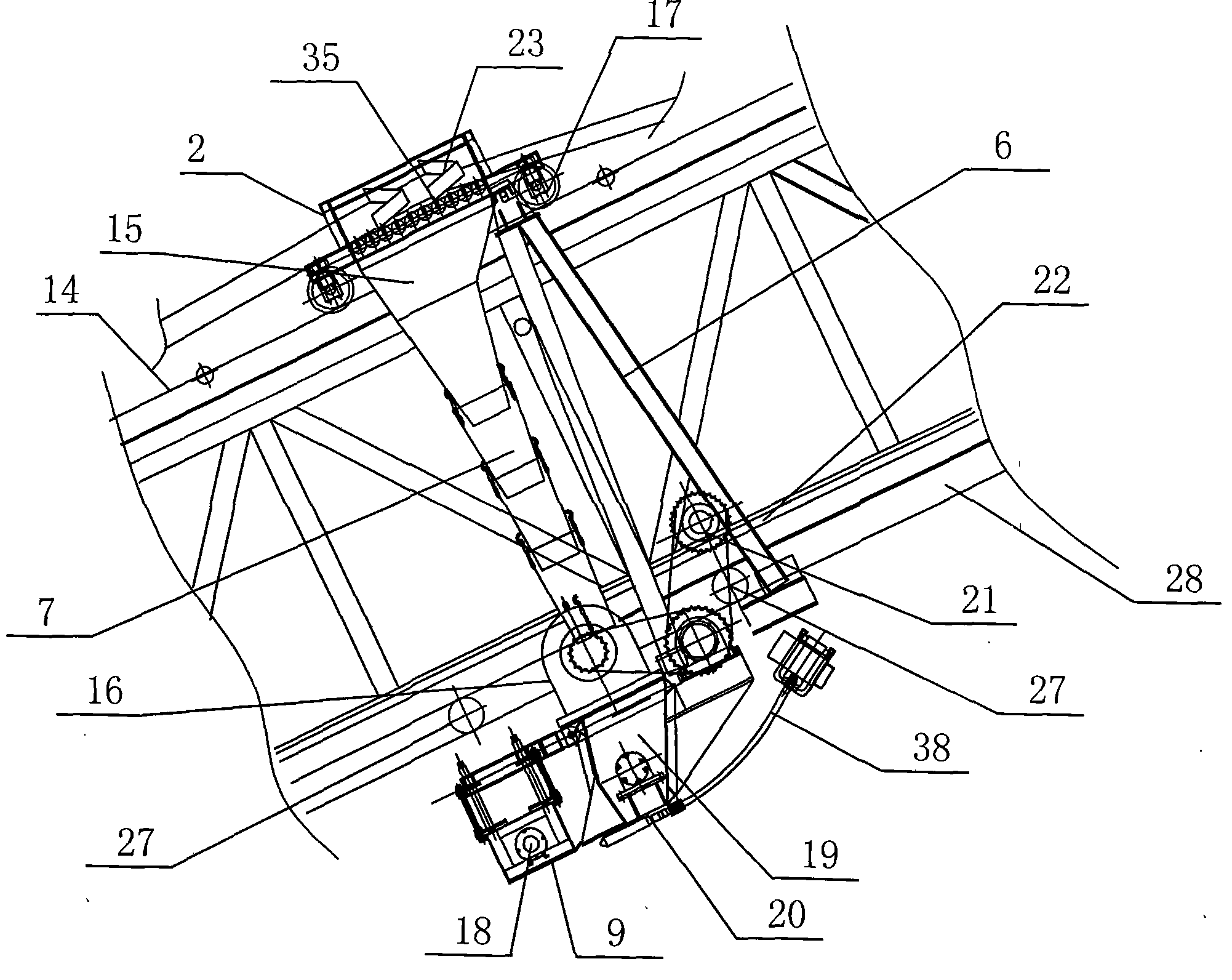

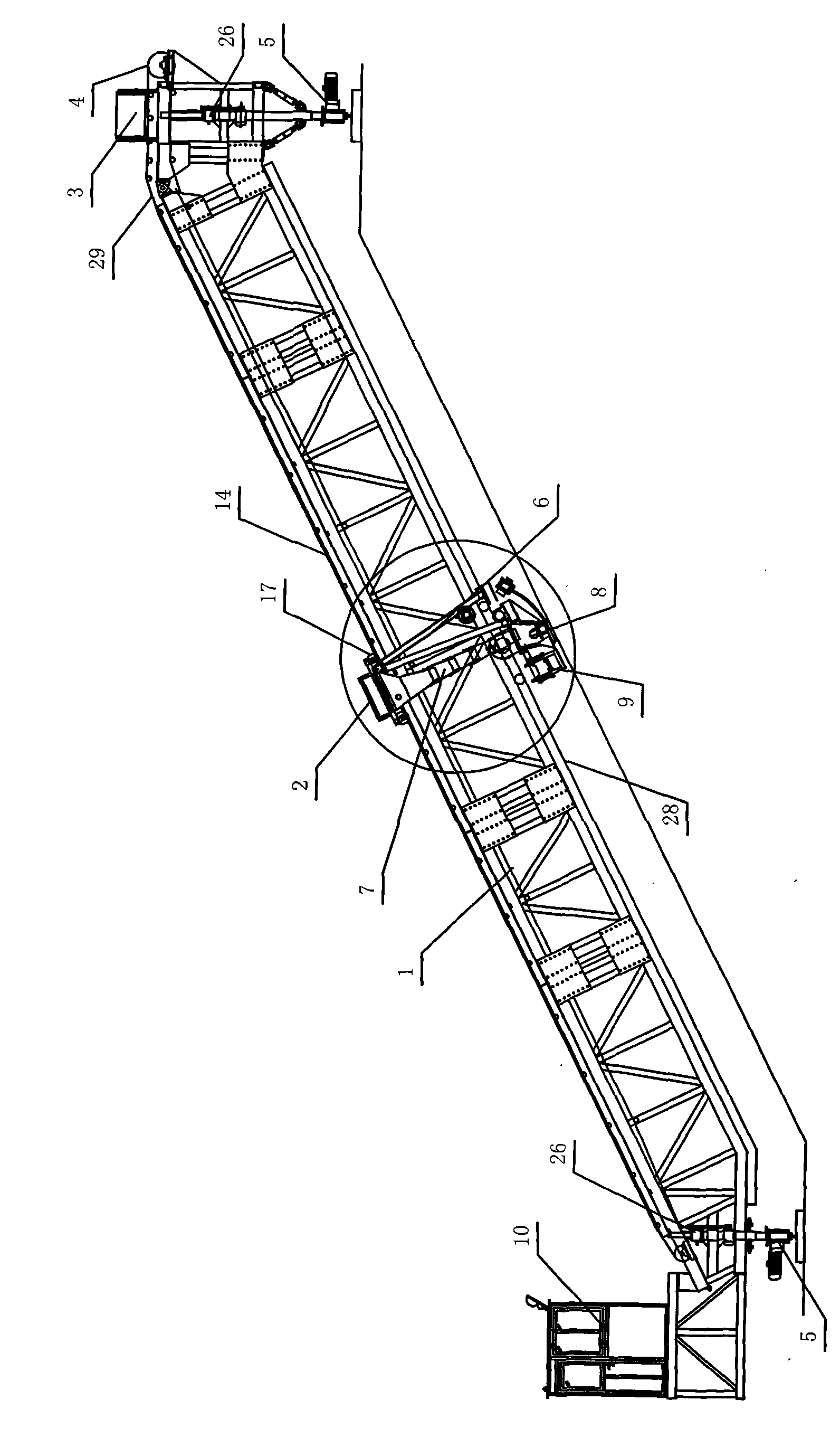

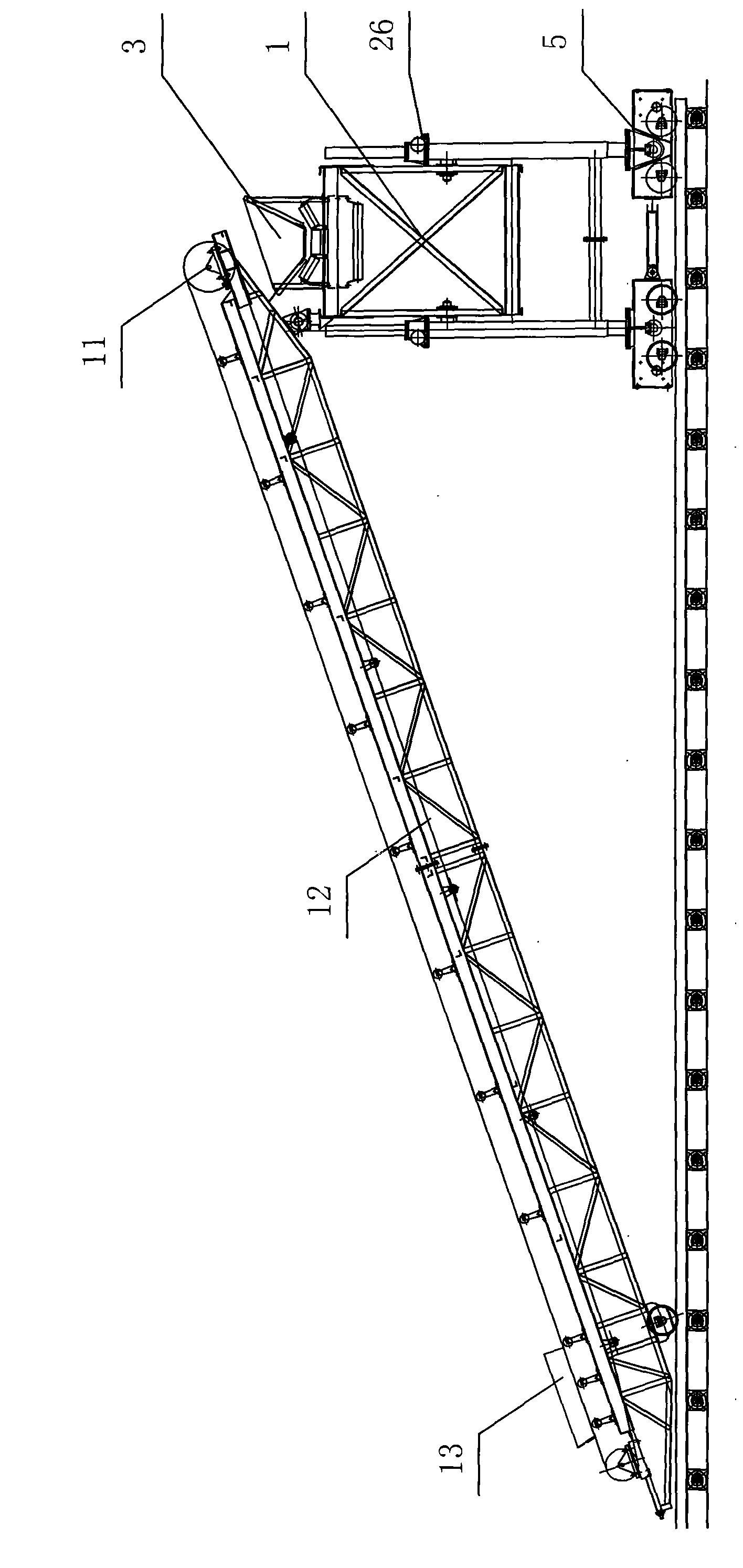

The invention relates to a large-span concrete slope masonry machine, comprising a main truss, a main material-receiving hopper, a main belt machine, an upper discharging vehicle and a lower discharging vehicle arranged on the main truss, material-conveying systems arranged on the upper discharging vehicle and the lower discharging vehicle and a forming system arranged on the lower discharging vehicle; the upper discharging vehicle is arranged on a track at the upper end of the main truss by an upper traveling wheel; the lower discharging vehicle is arranged on a track of the lower end of themain truss by a lower discharging wheel; a connecting shifting fork is arranged between the upper discharging vehicle and the lower discharging vehicle; a traveling motor is arranged on the lower discharging vehicle which is provided with a traveling transmission gear meshed with a rack track on the main truss; the lower traveling wheel is embedded into the track of the lower end so as to lead the traveling transmission gear of the lower discharging vehicle of a paver to operate thereon stably and reliably; and the large-span concrete slope masonry machine can accurately control the positionsof the upper discharging vehicle and the lower discharging vehicle in the processes of conveying materials, distributing materials and forming, thus leading the positions of conveying materials and distributing materials to be controlled precisely and guaranteeing the quality of the whole slope masonry.

Description

A large-span concrete slope masonry machine technical field The invention relates to a large-span concrete slope masonry machine. technical background In the world-renowned South-to-North Water Diversion Project started in my country, most of the channel cross-sections are open channel projects, and the surface is made of cast-in-place concrete. Whether it is the east line or the middle line, the amount of canal slope masonry is very large. In order to ensure the construction quality and construction period requirements of the concrete masonry on the slope, each construction unit can only use mechanized construction. At present, foreign channel lining equipment manufacturers mainly include GOMACO in the United States, Massenza in Italy, G&Z in the United States, Racho Hasson in the United States and Wirtgen in Germany. The company; only the canal lining equipment developed by Shandong Water Diversion Engineering Technology Research Center during the construction of the E...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E02D15/00

Inventor 赵良恒吕连英任建录王文田王乃超吕贵敏王志彬张立振李彦平

Owner 河北省水利工程局集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com