Locomotive car wheel fault detecting device based on phased array probe

A phased array probe and defect detection technology, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, can solve the problems of strict probe layout requirements, small structural differences, and long surface distances, achieving a small number of probes and convenient online The effect of detection and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

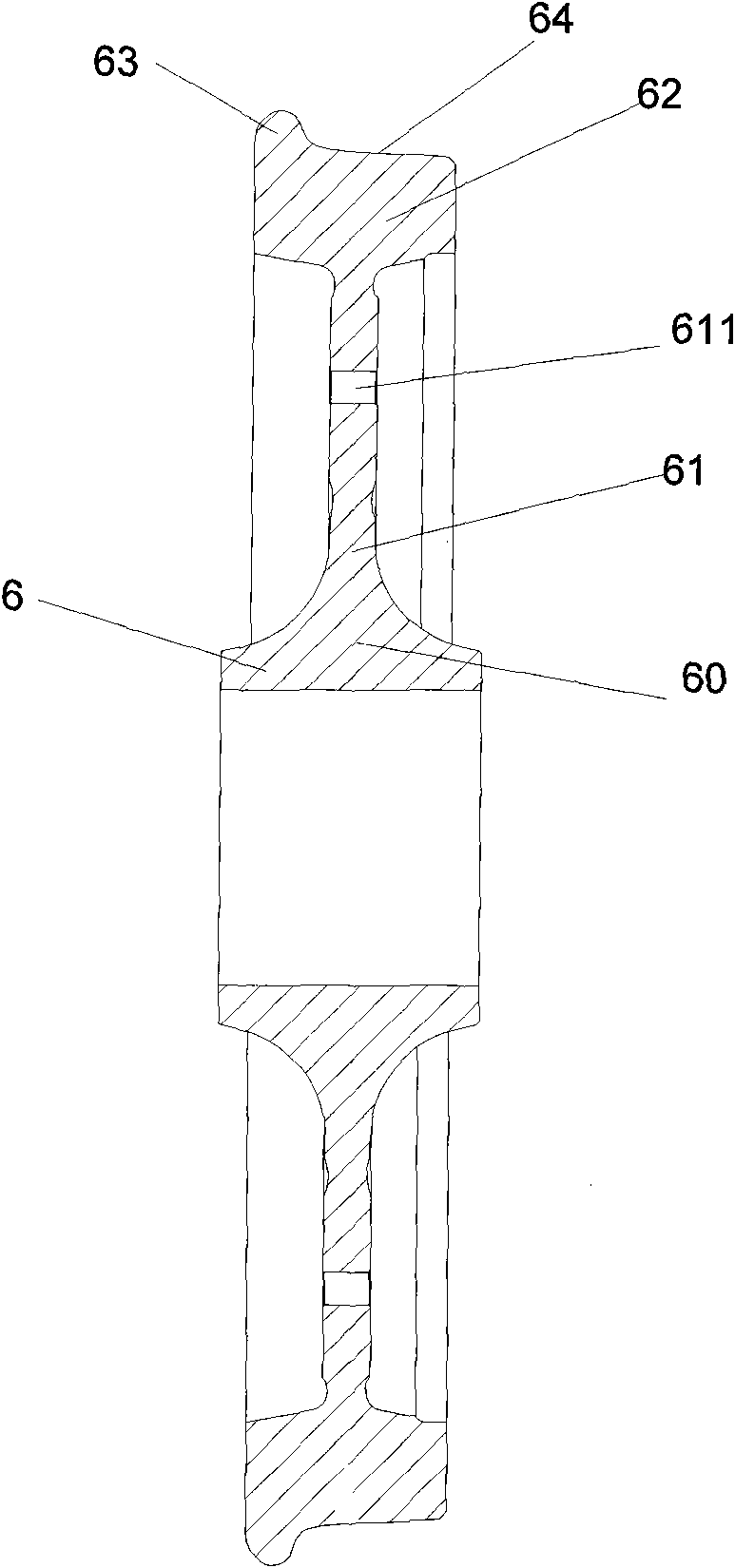

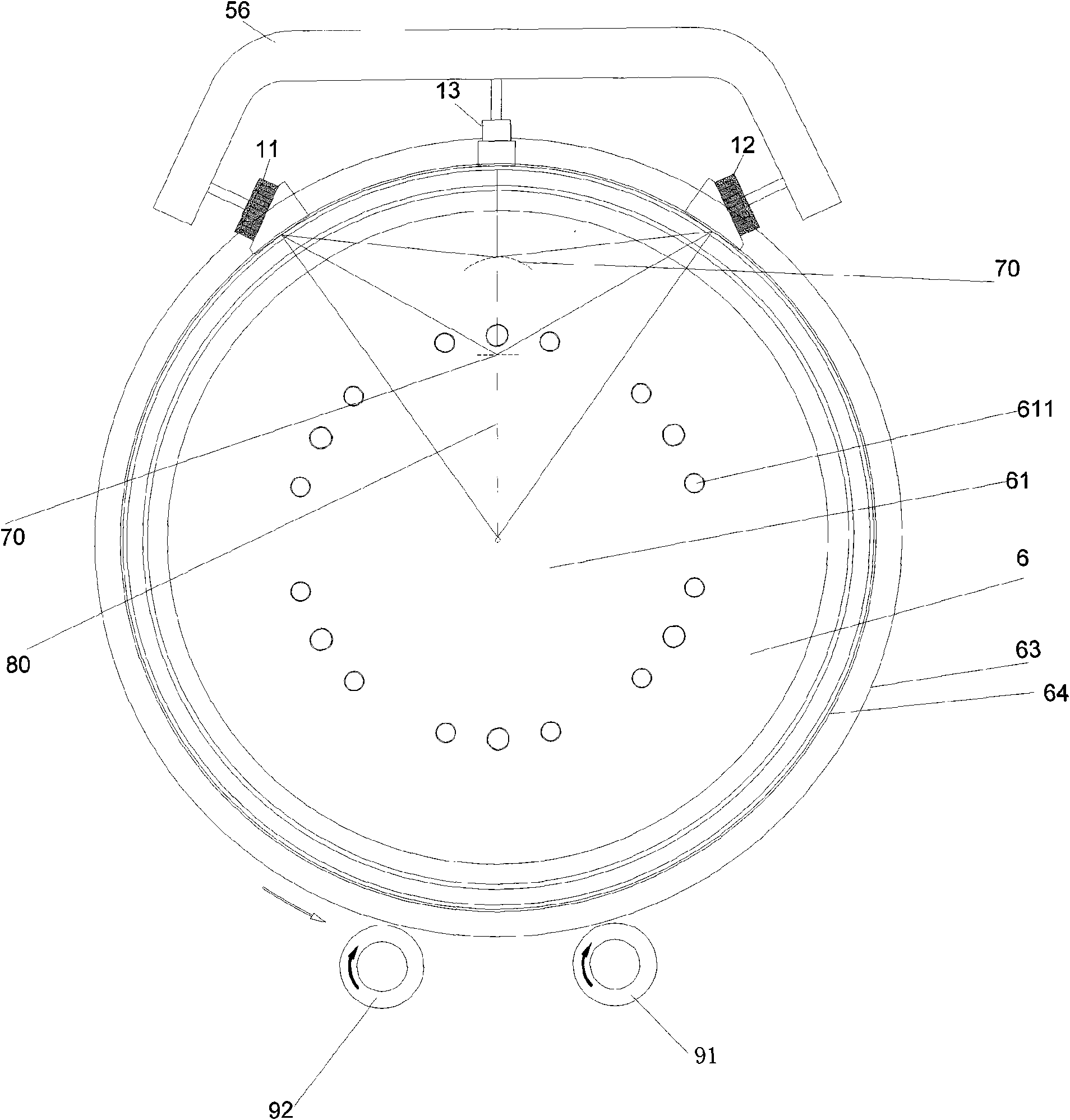

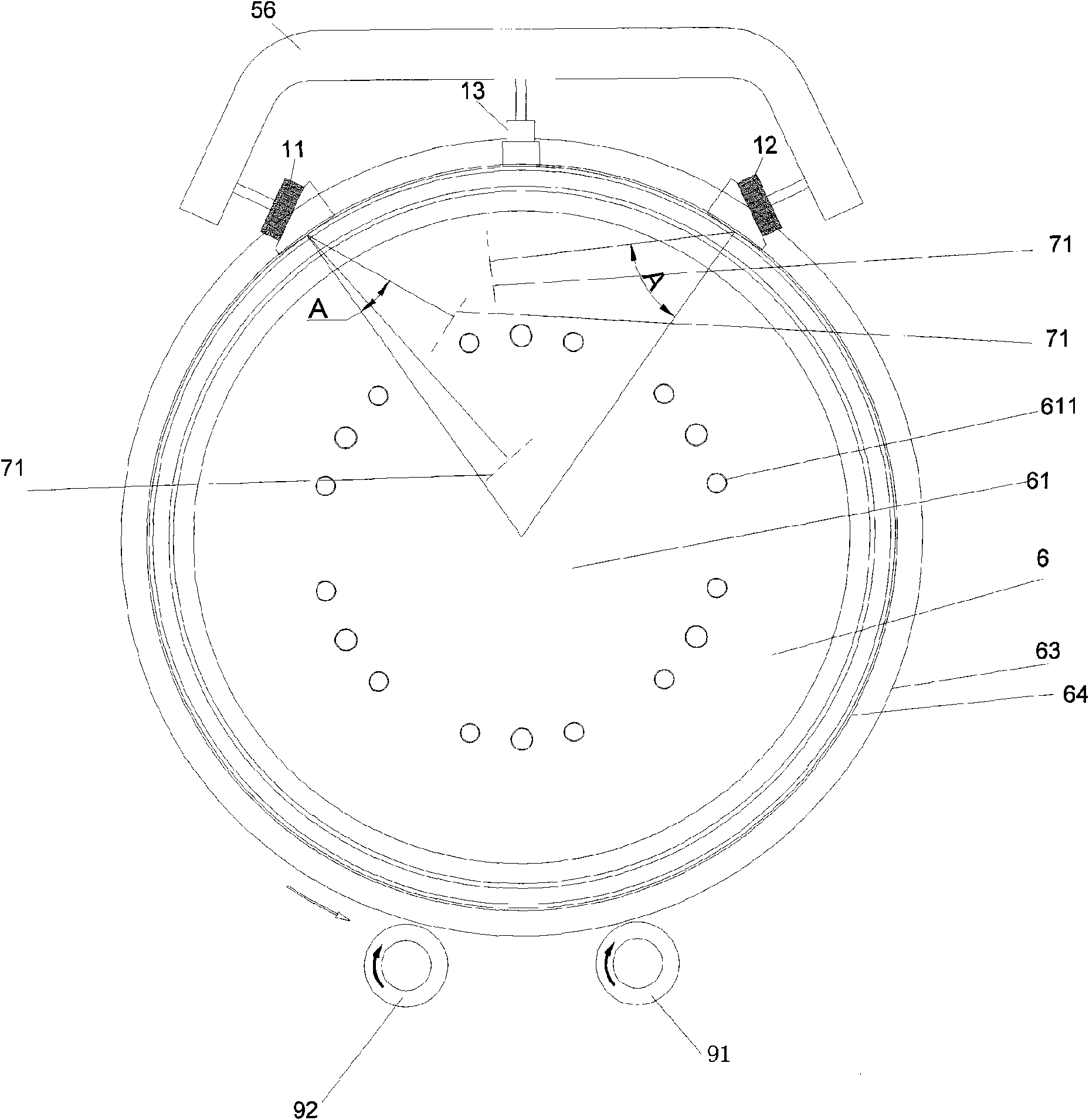

[0035] figure 2 , 3 , 4 show that a specific embodiment of the present invention is: a vehicle wheel defect detection device based on a phased array probe, the equipment is connected with an ultrasonic phased array probe on the probe bracket 56 connected to the control mechanism, The phased array probe is placed on the tread 64 of the two wheels 6 of the wheel set, and the lower part of the wheel tread 64 is placed on the top wheel 91 and the runner 92 of the top runner device; the ultrasonic phased array probe is connected with the data processing and control computer ;

[0036] The phased array probe has two left and right probes 11, 12. The left probe 11 and the right probe 12 are respectively located on the left and right sides of the vertical diameter of the wheel 6. The arc length between the two on the wheel rolling circle 69 is 220 ~ 600mm; and the left probe 11 and the right probe 12 are located on the side of the tread 64 away from the rim 63, and the axial distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com