Positive pole material for lithium ion battery, positive pole for lithium ion battery and lithium ion battery

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, secondary batteries, active material electrodes, etc., can solve problems such as poor high-temperature cycle performance, achieve long high-temperature cycle life, reduce production costs, and improve high-temperature performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022]The preparation method of the positive electrode material of the lithium ion battery provided by the invention is simple, just by uniformly mixing various components forming the positive electrode material.

[0023] According to the positive electrode of the lithium ion battery provided by the present invention, the current collector can be various current collectors commonly used in this field, for example, it can be aluminum foil, copper foil or punched steel strip. In a specific embodiment of the present invention, aluminum foil is used as the positive electrode conductive substrate.

[0024] The positive electrode of the lithium ion battery can be prepared by first mixing and stirring the solvent, the conductive agent and the binder to form a slurry, then adding the positive electrode active material, the binder and the conductive agent to the slurry, and then stirring, drawing the slurry, Manufactured by drying, rolling and cutting. The type and amount of the solve...

Embodiment 1

[0033] This embodiment is used to illustrate the lithium ion battery positive electrode material, lithium ion battery positive electrode and lithium ion battery provided by the present invention and their preparation methods.

[0034] (1) Preparation of positive electrode

[0035] 8.8 kg of N-methylpyrrolidone (NMP), 1 kg of acetylene black and 0.2 kg of polyvinylidene fluoride (PVDF) powder were mixed and stirred for 5 minutes to prepare acetylene black slurry.

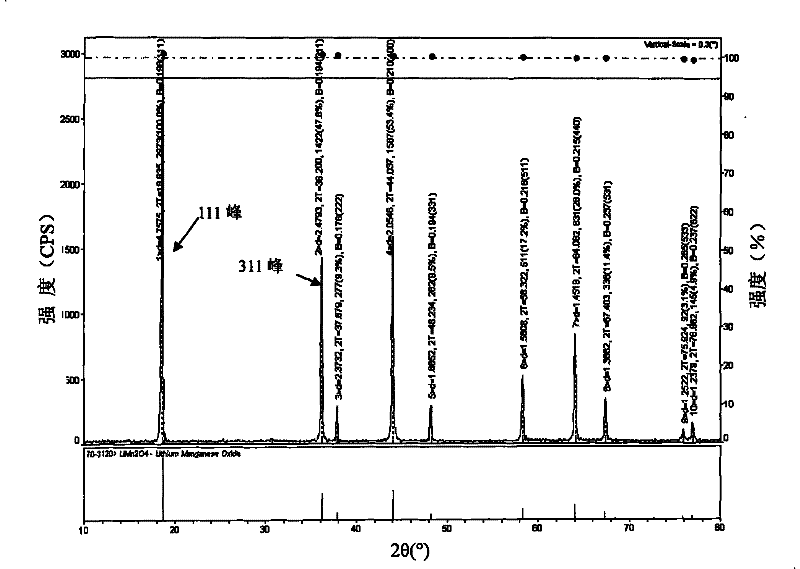

[0036] Take 2 kilograms of the above-mentioned prepared acetylene black slurry, add 3 kilograms of N-methylpyrrolidone (NMP), 9.5 kilograms of lithium cobaltate (produced by Hunan Ruixiang Company, particle diameter 8 μm), 0.5 kilograms of 311 peak relative intensity is 47.8% Lithium manganese oxide (produced by Hunan Ruixiang Company, the particle diameter is 11 μm, the XRD figure is as follows figure 1 As shown, wherein 2θ is 36.1 ° peak is 311 peak, 2θ is 18.6 ° peak is 111 peak), 0.3 kilograms of polyvinylidene ...

Embodiment 2

[0043] This embodiment is used to illustrate the lithium ion battery positive electrode material, lithium ion battery positive electrode and lithium ion battery provided by the present invention and their preparation methods.

[0044] 9.45 kg of N-methylpyrrolidone (NMP), 0.05 kg of carbon nanotubes and 0.5 kg of polytetrafluoroethylene powder were mixed and stirred for 5 minutes to prepare a carbon nanotube slurry.

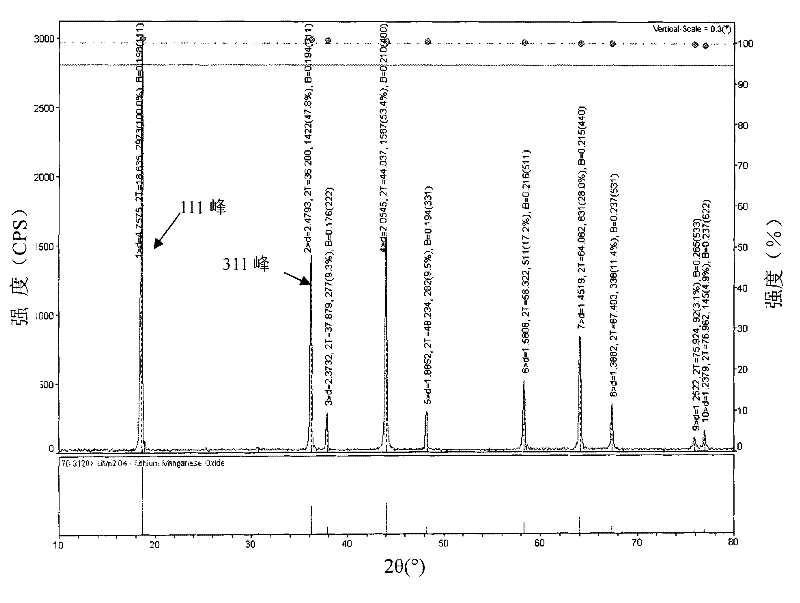

[0045] Take 2 kg of the carbon nanotube slurry prepared above, add 3 kg of N-methylpyrrolidone (NMP), 9 kg of lithium cobaltate (produced by Hunan Ruixiang Company, particle diameter 14 μm), 1 kg of 311 peak relative intensity of 58.0% Lithium manganate (produced by Toda Industry, particle diameter is 19 μm, 2θ is 35.8 ° peak is 311 peak in XRD spectrogram, 2θ is 18.2 ° peak is 111 peak), 0.4 kilogram of polytetrafluoroethylene, stirring After 20 minutes, the lithium ion battery positive electrode material of the present invention is obtained. Next, prepare the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com