Method for processing end heads of bundled linear spring steel wires

A technology of spring steel wire and processing method, applied in rigid containers, containers with multiple items, closing, etc., can solve problems such as operator or equipment injury, and achieve the effect of low comprehensive cost and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

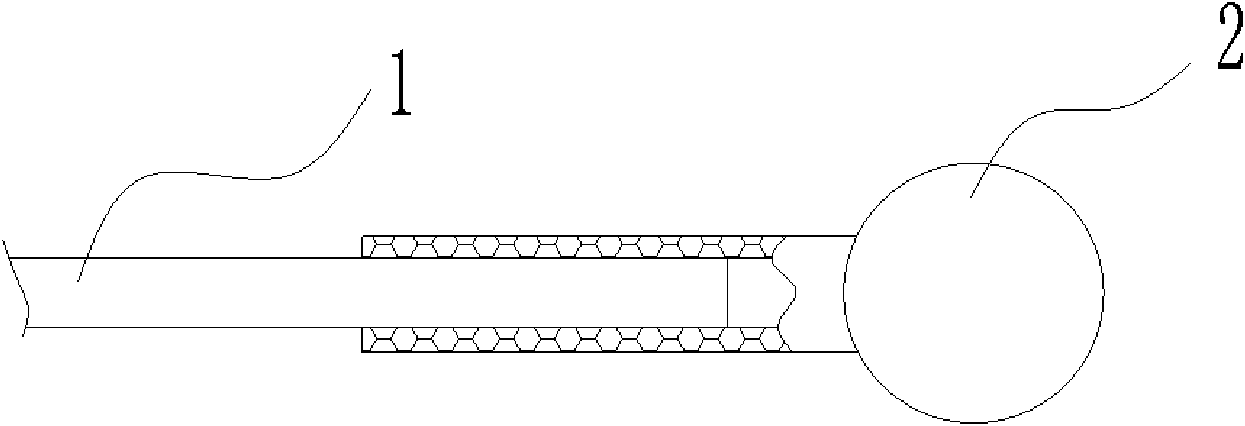

[0023] Embodiment one: if figure 2 As shown, we insert the spherical sleeve 2 at the beginning end and the end end of each bundle of linear spring steel wire 1, and the spherical sleeve 2 is provided with a cylindrical body, which is hollow in the axial direction, and the hollow size is the same as the cross-sectional size of the linear spring steel wire 1. Similarly, the end of the linear spring steel wire 1 is inserted into the cylindrical body of the spherical sleeve 2 with an interference fit, the spherical sleeve 2 is put on at the end of each bundle of linear spring steel wire, and the spherical sleeve 2 is removed when making the spring , and recycled.

Embodiment 2

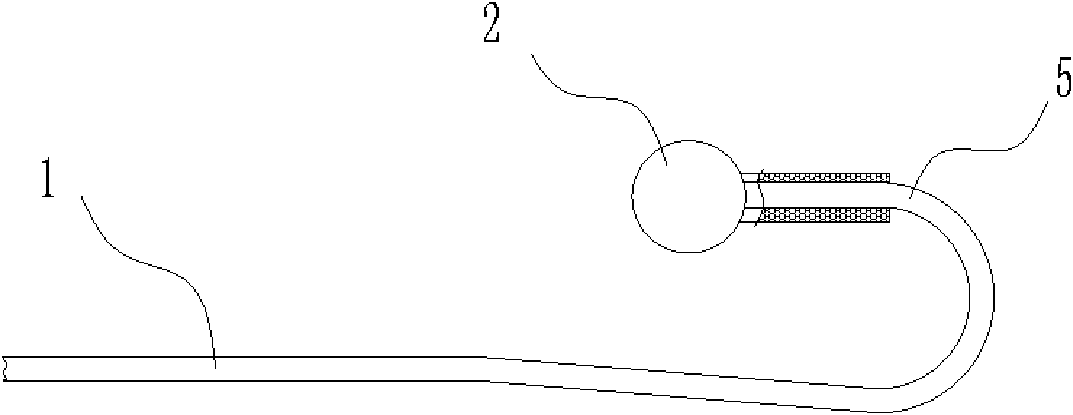

[0024] Embodiment two: see image 3 , in order to provide the linear spring steel wire 1 that draws bundles to have a fixed point of bundling, the starting end of spring steel wire 1 is bent into crotch 5 with the end end, puts spherical cover 2 again.

Embodiment 3

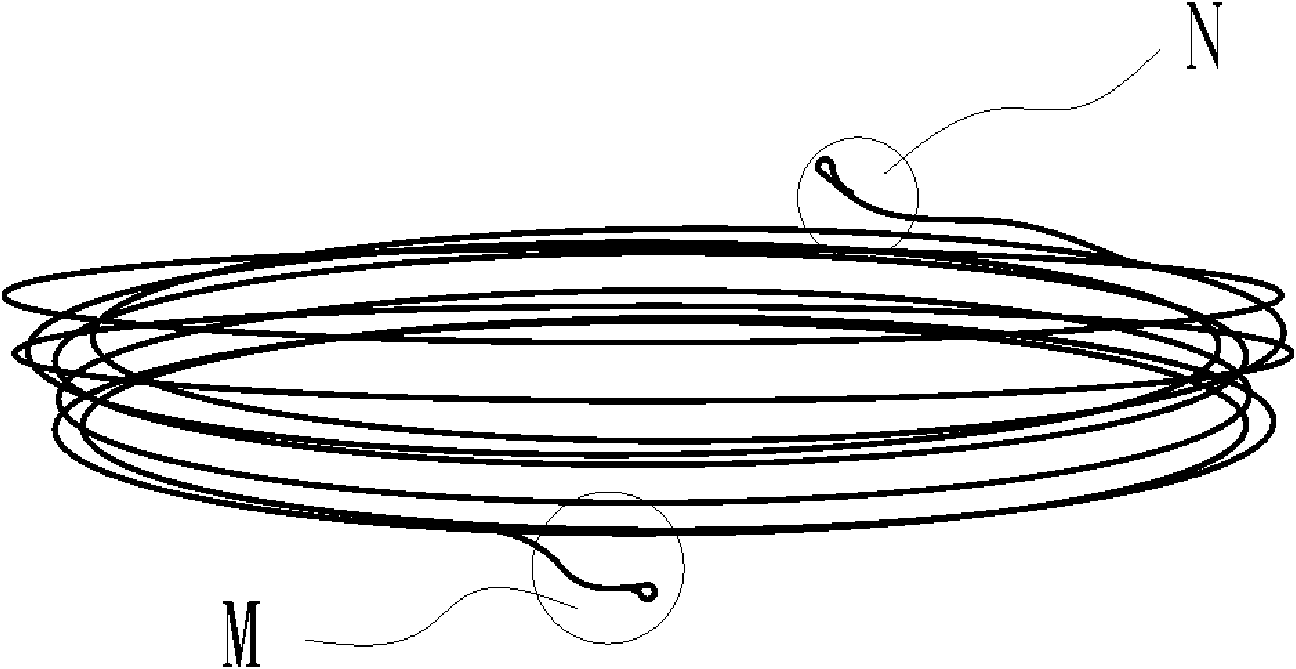

[0025] Embodiment three: as Figure 4 As shown, the end of the linear spring steel wire 1 is directly bent into an earring 11, and the earring 11 is oval, and the end of the linear spring steel wire 1 is bent back to be close to the linear spring steel wire 1 of its own straight line. , also can first put soft plastic cover on the end of the linear spring 1 that is not bent, and then bend and shape, so as to achieve safety effect equally.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap