Variable frequency speed regulating system of high-frequency vibrating motor

A technology of frequency conversion speed regulation and high frequency vibration, applied in the direction of controlling multiple AC motors, etc., can solve the problems of reducing the service life of the system, cluttered lines, and easily damaged inverters, to ensure safe operation, improve wiring efficiency, and reduce complexity. degree of effect

Active Publication Date: 2010-02-10

WOLONG ELECTRIC GRP CO LTD +1

View PDF0 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

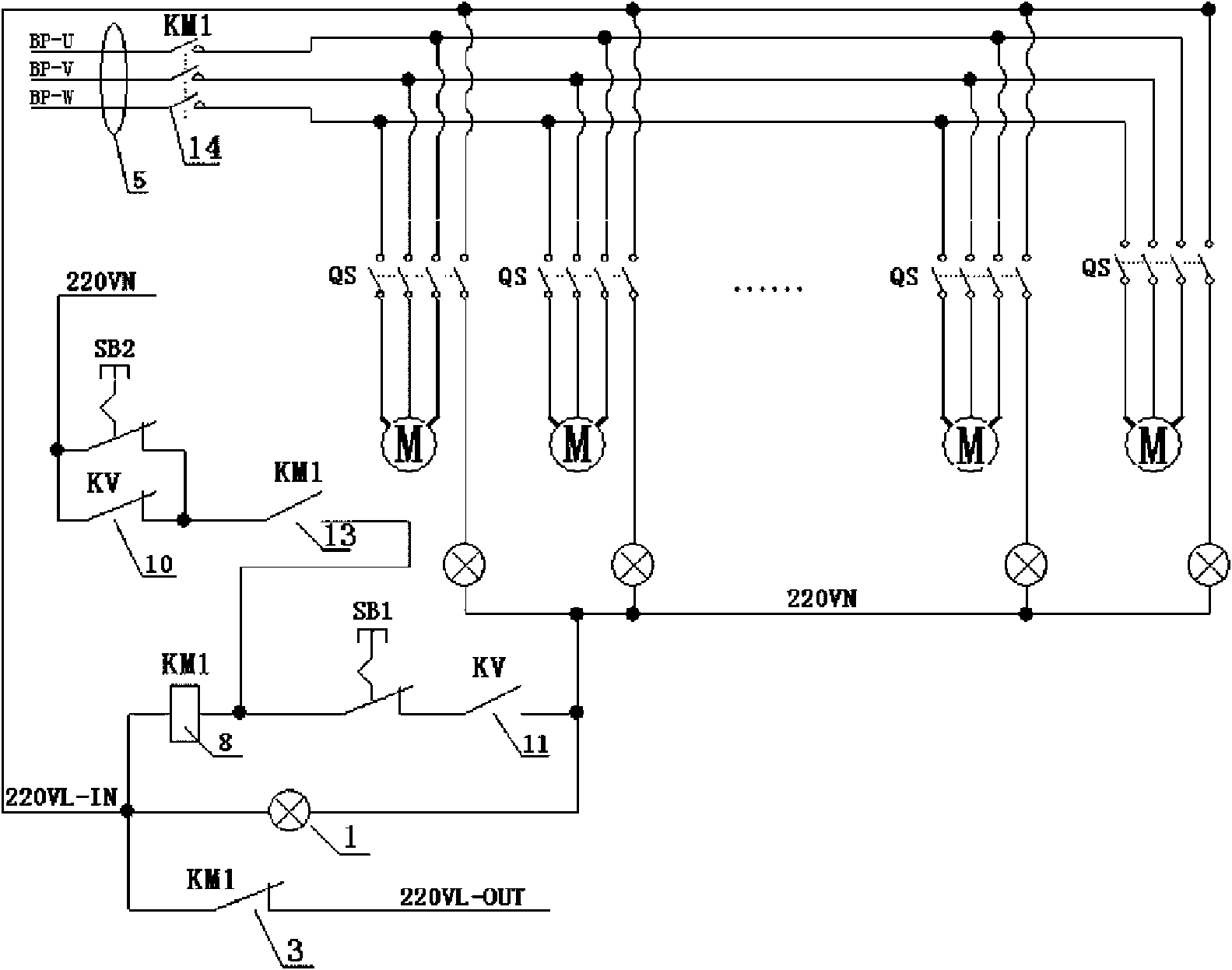

In order to prolong the service life of the components when the system is working, it is required to do the following: 1. The motor adopts soft start to protect the motor and the frequency converter, first start the branch control cabinet, and then start the frequency converter; 2. When stopping, first turn off the frequency converter Output and then close the branch control cabinet to prevent arcing between the contacts of the AC contactor; 3. The branch control cabinet is interlocked during operation, that is, only one branch control cabinet is allowed in a branch control cabinet connected to an inverter When the control cabinet is powered on, other branch control cabinets must be powered off. If the user starts two branch control cabinets at the same time, especially the second branch control cabinet, it will easily cause damage to the inverter.

The current system cannot meet the requirements of the first and second points, resulting in the inverter being easily damaged, and the phenomenon of arcing of the AC contactor, which increases the maintenance cost of the system and reduces the service life of the system

For the third requirement, the AC contactor and the auxiliary contact of the AC contactor are often interlocked at present, or the start / stop buttons of other branch circuit control cabinets are connected in series to the start / stop button of the branch circuit control cabinet. The wiring is very complicated, which brings trouble to the wiring, and is prone to failure, which is not easy to repair

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

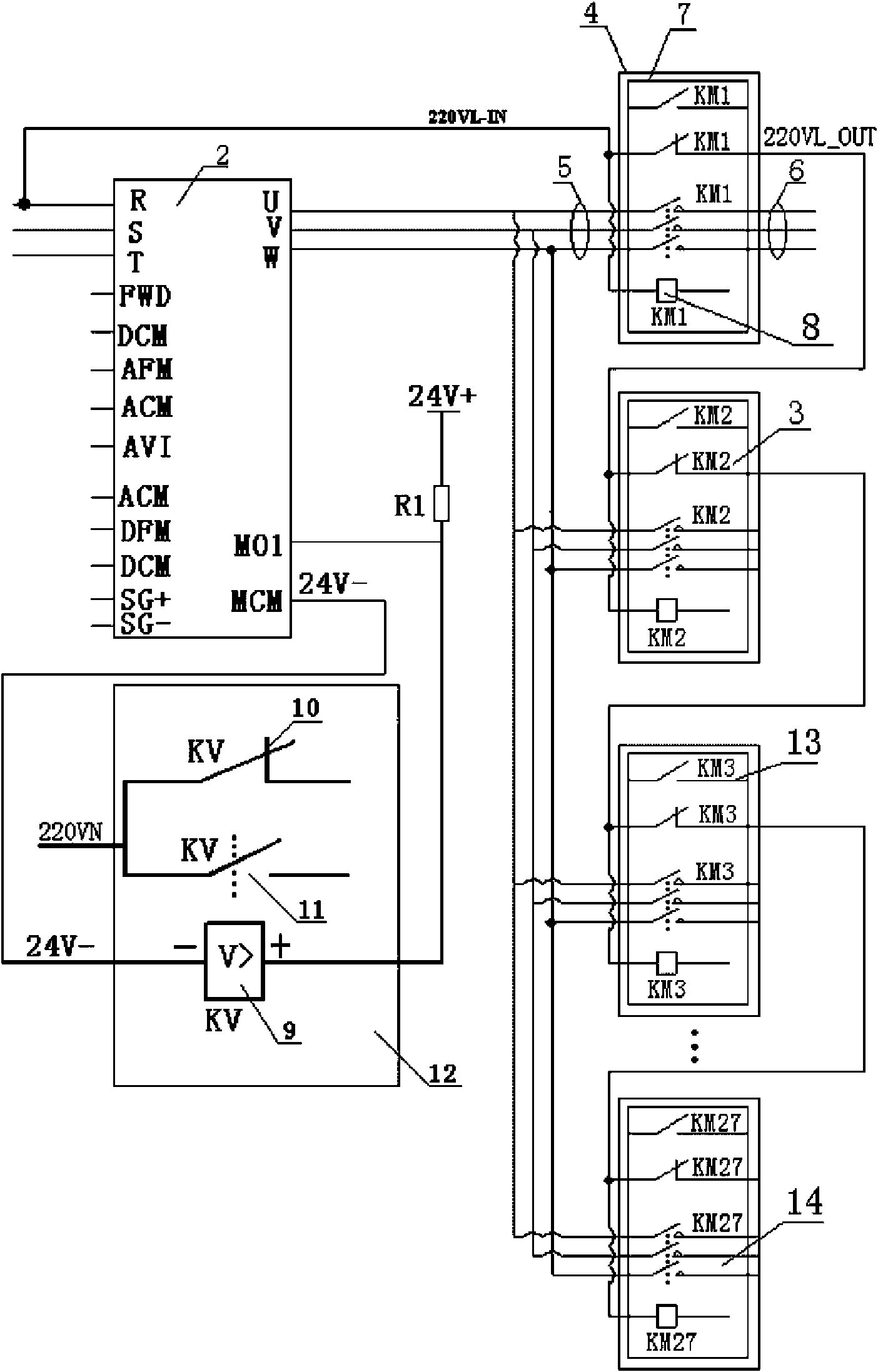

[0025] Embodiment two, such as image 3 As shown, the difference from the first embodiment is that the coil of the relay 12 is energized when the frequency converter 2 is working. Therefore, it is necessary to set the normally open contact 11 of the corresponding relay 12 in the stop circuit, and set the normally closed contact 10 of the relay 12 in the start circuit.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

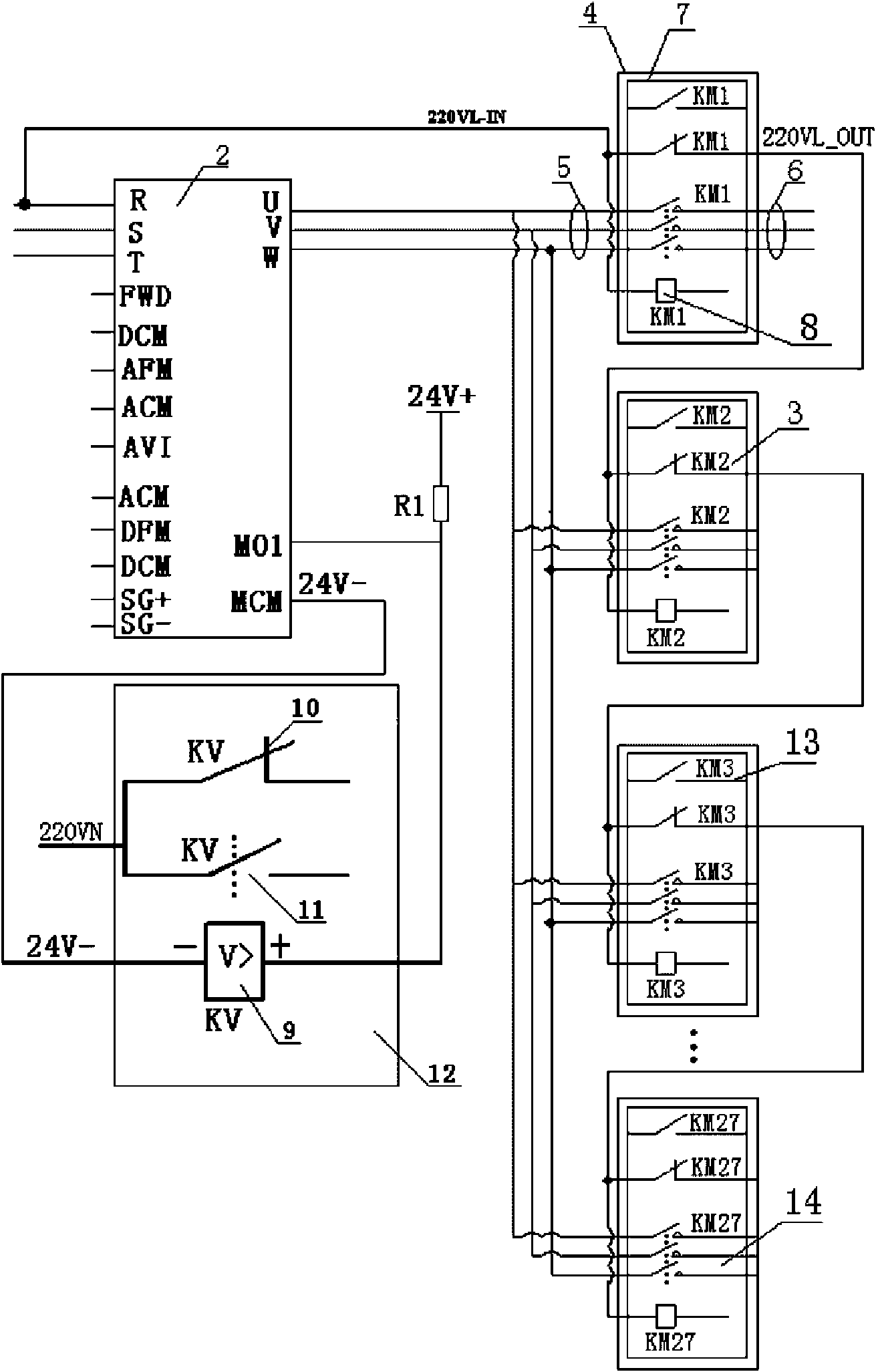

A variable frequency speed regulating system of a high-frequency vibrating motor is disclosed, relating to construction tool. The motor in present system is incapable of achieving soft start and is liable to, while cessation, damage a frequency converter and arc in an AC contactor due to failing to forbid a branch control cabinet being closed on condition that the frequency converter is in operation, thus bringing potential safety jeopardy while raising the maintenance cost of system, and the interlock circuit is so complex as to be disadvantageous to inspection. A control circuit of the variable frequency speed control system comprises a detection circuit and a protection circuit, wherein, the detection circuit is provided with a signal detection end connected with a signal output end ofthe frequency converter, the detection circuit comprises a relay, the coil of which is serially connected in the detection circuit as well as a normally open contact and a normally closed contact of which are arranged in the protection circuit. The variable frequency speed control system of the high-frequency vibrating motor achieves the purpose of protecting the frequency converter and the AC contactor, prevents arc phenomenon of the AC contactor, enhances production safety while prolonging the service life of product, and has simple interlock circuit, which facilitates the inspection.

Description

【Technical field】 [0001] The invention relates to construction tools, in particular to a frequency conversion speed regulation system of a high-frequency vibration motor, which belongs to the field of manufacturing railway track infrastructure equipment. 【Background technique】 [0002] High-frequency vibration motor frequency converter speed control system is mainly used in the construction of concrete prefabricated components of high-speed railways, expressways, highway bridges, and engineering buildings. A set of high-frequency vibration motor frequency converter speed regulation system includes a frequency converter, a plurality of parallel branch circuit control cabinets connected to the frequency converter, and multiple parallel connection motors connected to the branch circuit control cabinet. Each branch circuit control cabinet controls all the motors on a concrete precast mold to run or stop at the same time, and each concrete precast mold has 8 to 9 motors. In orde...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H02P5/74

Inventor 付贵霖孙鑫陈平周军

Owner WOLONG ELECTRIC GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com