Coaxial separator

A separator, coaxial technology, applied in the field of separation, which can solve problems such as gas-solid or gas-liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

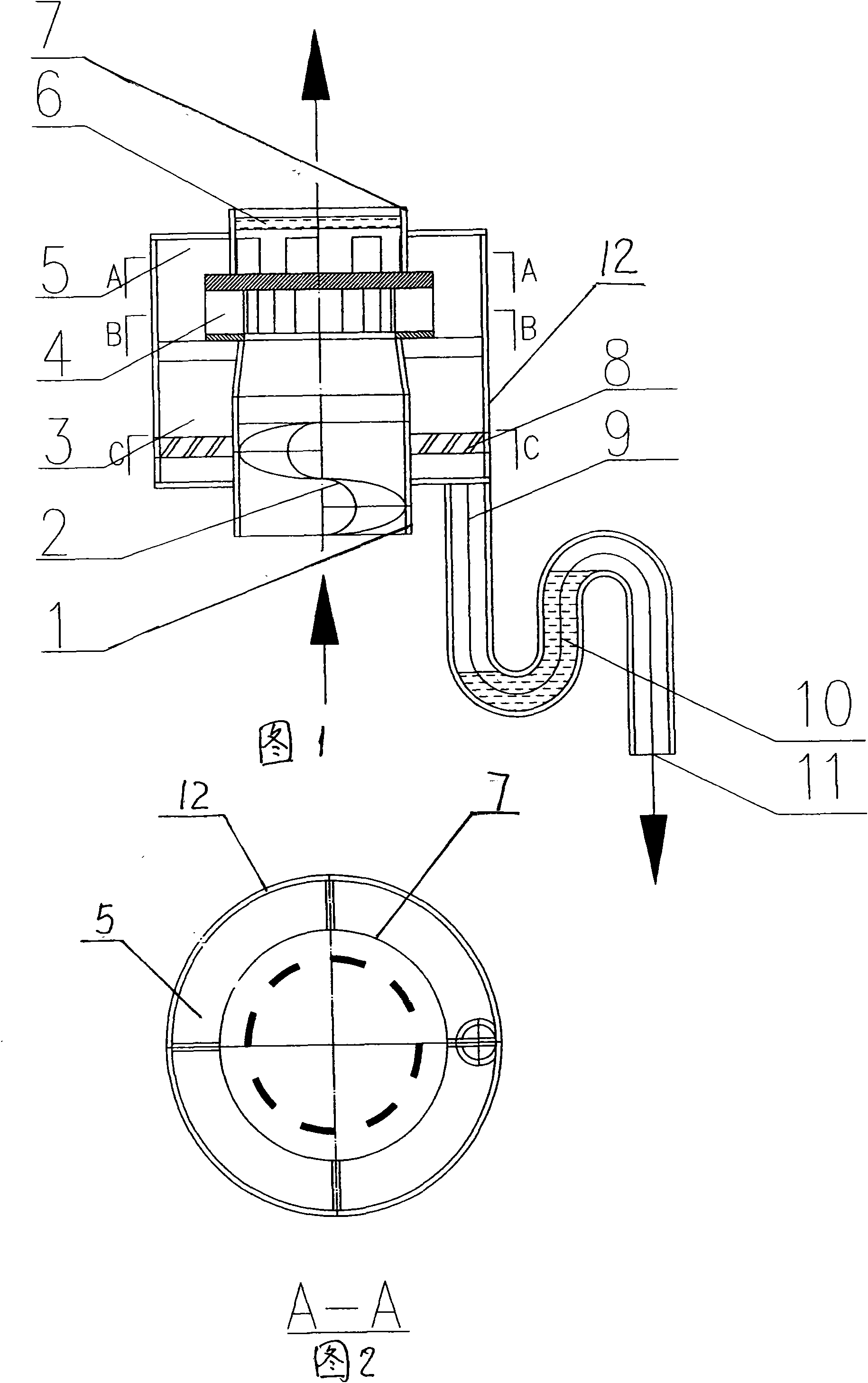

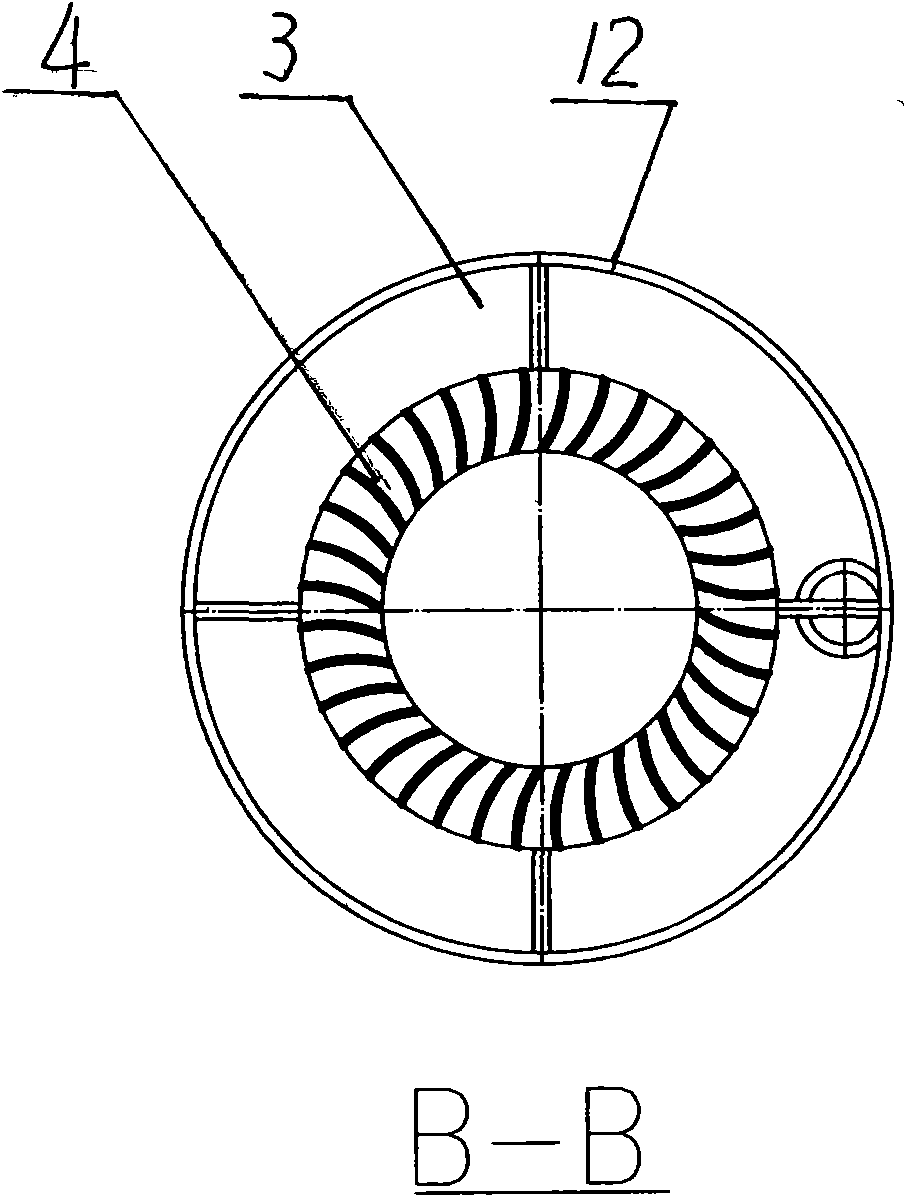

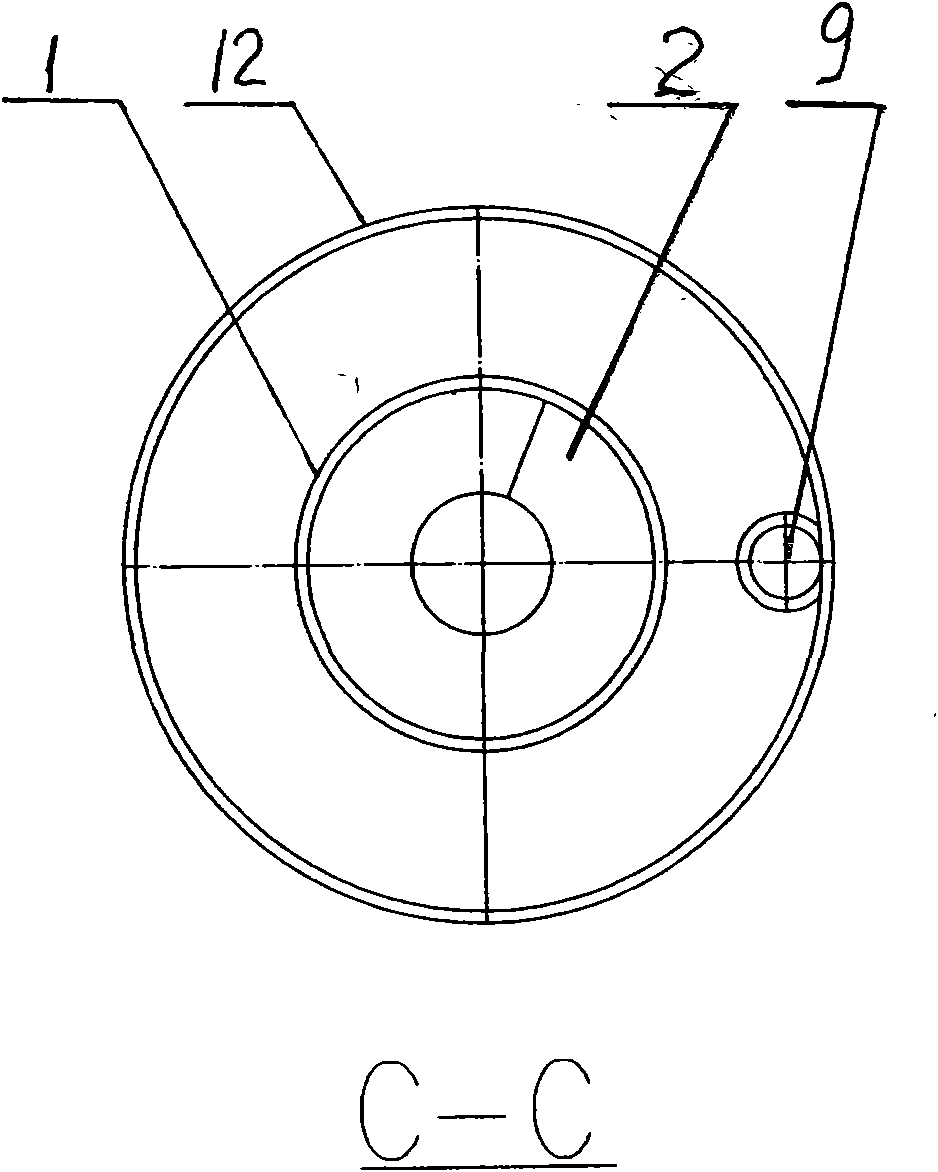

[0011] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0012] The swirl guide vane 2 is installed in the fluid inlet pipe 1, and the separator swirl area 4 is installed at the outlet of the fluid inlet pipe 1; between the fluid inlet pipe 1 and the separator shell 12, the liquid swirl guide vane 8 and the liquid outlet pipe are installed at the bottom. 9 and U-shaped liquid air seal pipe 10, the top is equipped with defoaming layer 6 and exhaust pipe 7.

[0013] When the fluid of the two media enters from the fluid inlet pipe 1 at the lower part of the equipment, it is pre-swirled through the swirl guide vane 2 to make the fluid rotate, and the swirling fluid enters the cyclone separator blade area 4 through the narrow annular slot High-speed centrifugal separation is carried out, and the liquid and gas are separated into the liquid separation zone 3, and then further separated by the liquid swirl gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com