Flexible roller contact molding rolling forming device

A roll forming, flexible roll technology, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of poor forming quality, low production efficiency, high labor intensity, etc., to reduce production costs and reduce forming force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

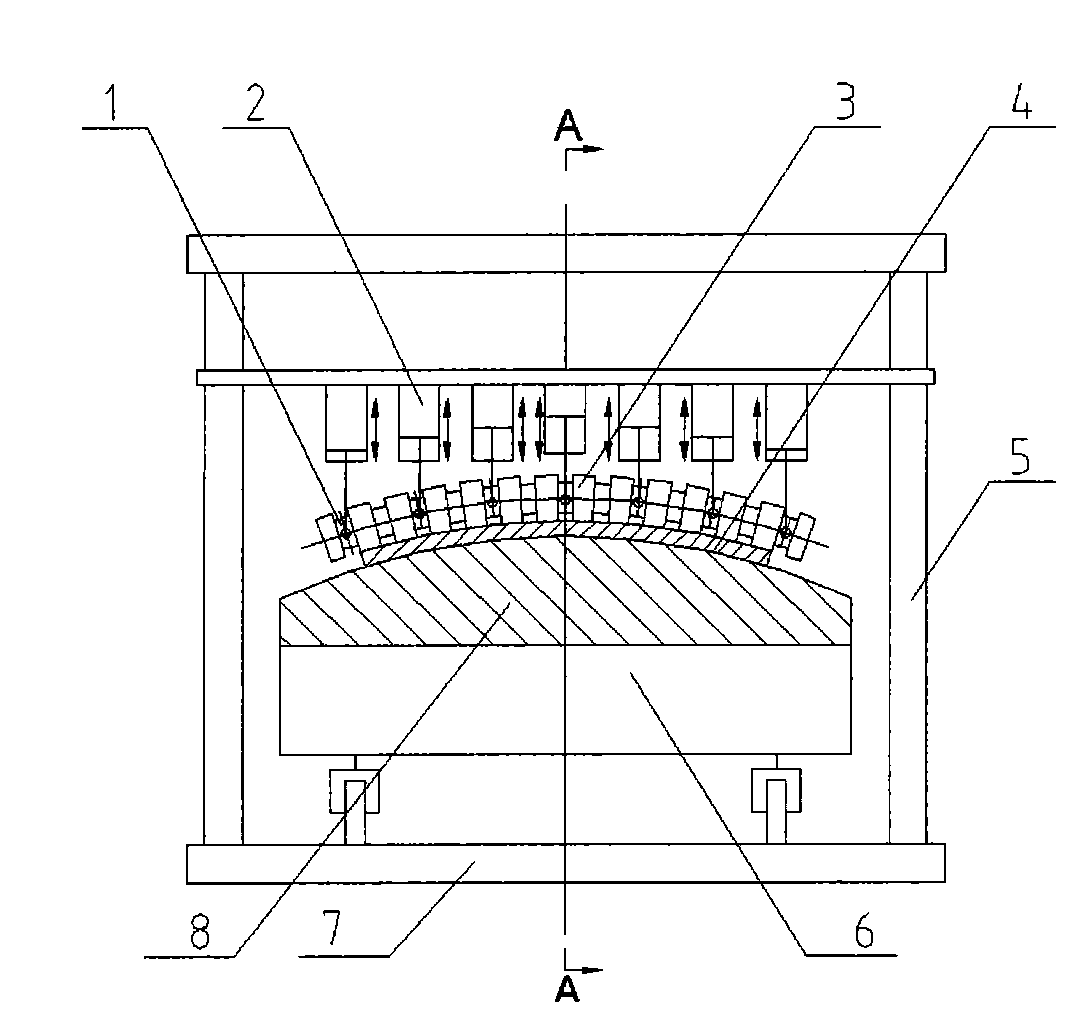

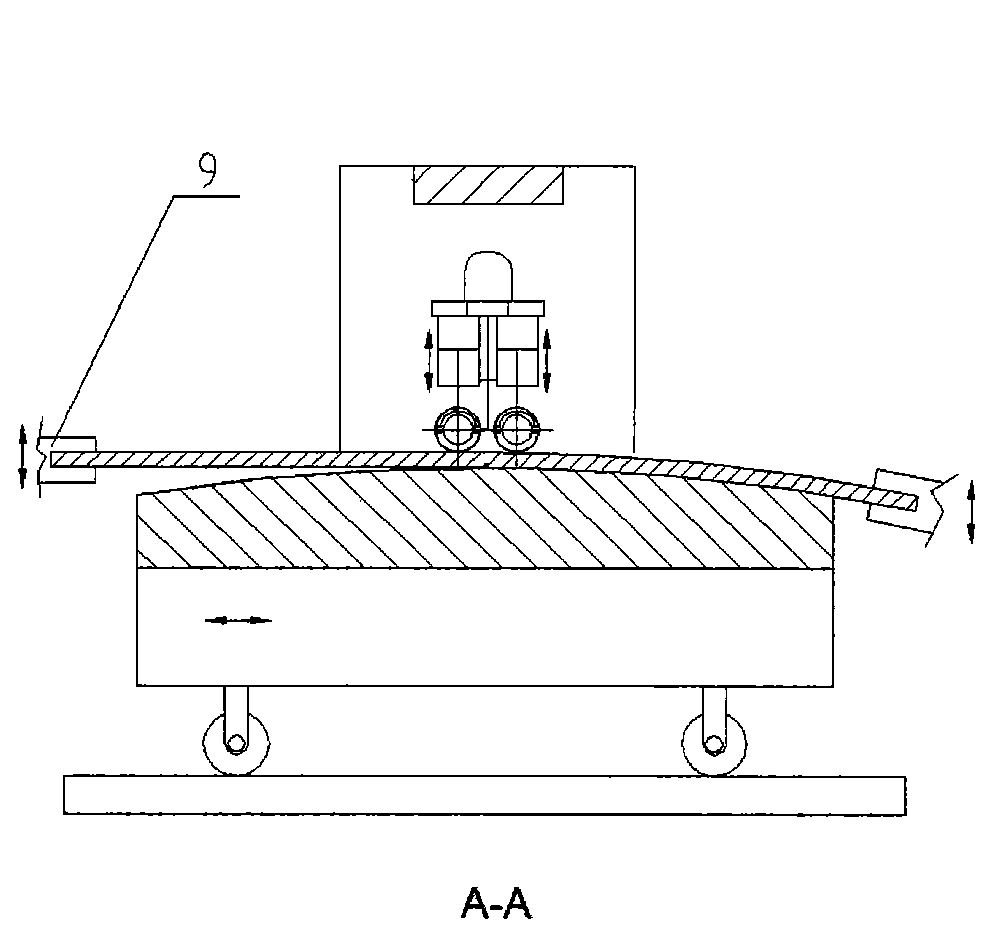

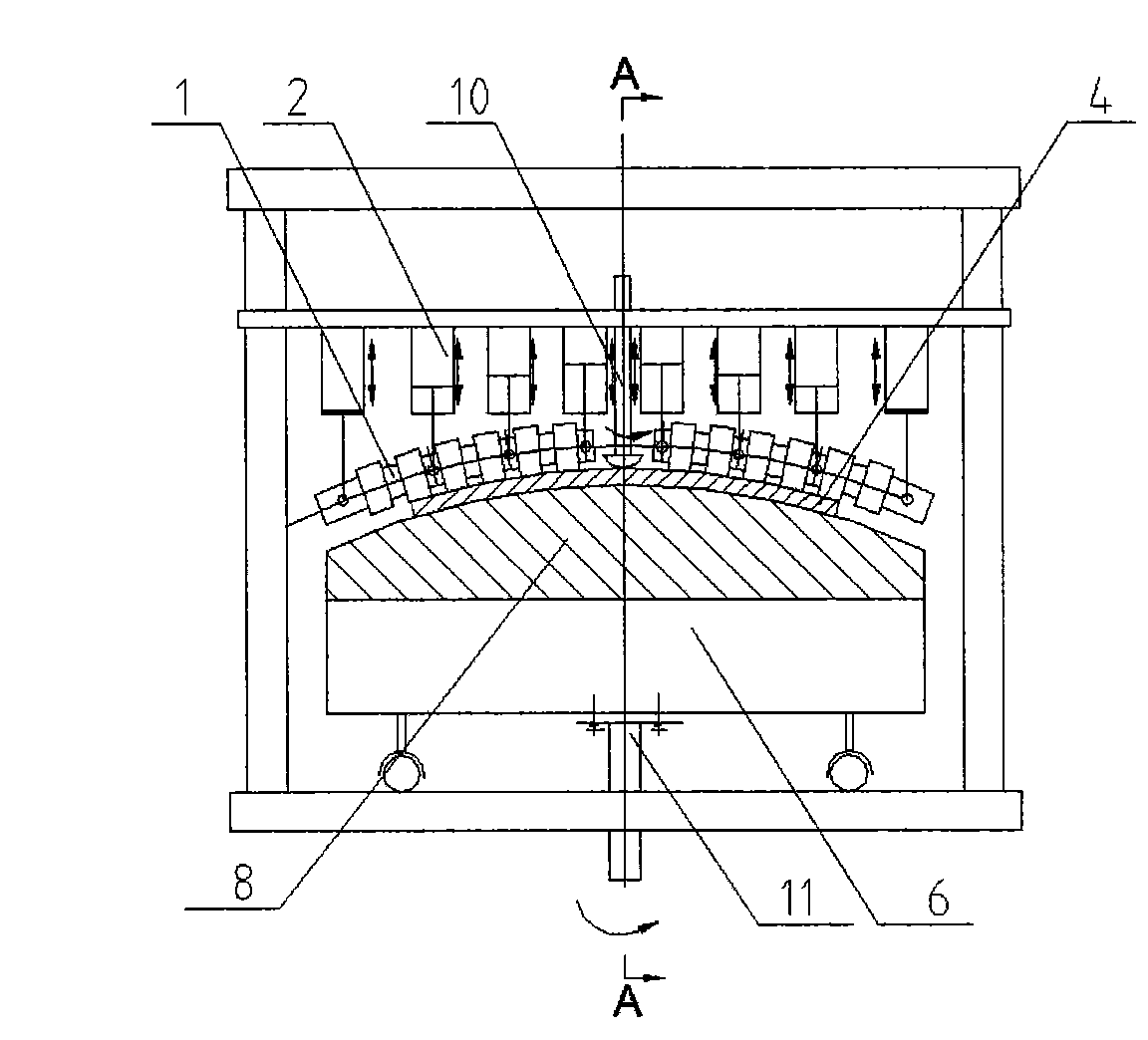

[0024] The specific content and working process of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0025] The flexible roller die-attaching and rolling forming device is composed of two sets of flexible working rollers, several flexible roller supporting mechanisms, brackets, bases and worktables. The flexible rollers are attached and rolled to the mold, or the rolling bearings and the mold are installed on it. Fitting and rolling, the axis of the flexible roll can passively bend with the mold surface on the table.

[0026] The flexible roller is composed of one or several kinds of elastic elements such as steel wire flexible shaft, steel wire rope, coil spring, polyurethane rubber, etc., and can also be composed of several rigid sub-rollers. Several support mechanisms are arranged on the flexible roller or the rigid sub-roll. When the flexible roller interacts with the mold surface of different he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com