Environmental friendly heat transfer printing ribbon for printing cloth mark by scroll machine and preparation method thereof

An environmentally friendly, banner machine technology, used in printing, ink ribbons, inking devices, etc., can solve the problems of easy falling off and insufficient firmness, and achieve the effect of improving efficiency, printing quality and printing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

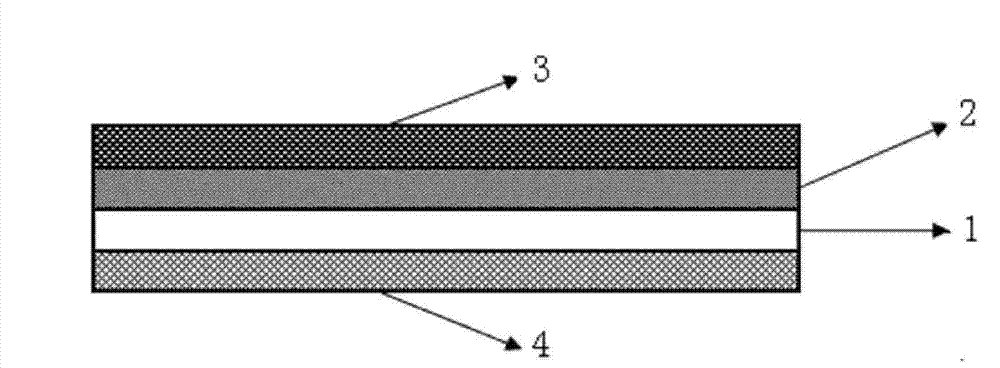

[0031] Such as figure 1 As shown, the environment-friendly thermal sublimation tape used for printing cloth labels on a banner machine according to the present invention consists of a tape base film 1, a peeling layer 2 coated on one side of the tape base film 1, and an ink layer 3 coated on the peeling layer 2. Composed of the heat-resistant back layer 4 coated on the other side surface of the tape base film 1, the total thickness of the sublimation tape is 6.7-35.5 microns.

[0032] The tape base film is 4-7 microns thick, the peeling layer is 0.5-5 microns thick, the ink layer is 2-23 microns thick, and the heat-resistant back layer is 0.2-0.5 microns thick. The total thickness of the thermal transfer sublimation tape in this embodiment is 10.7 microns. The base film 1 is 4.5 microns thick, the release layer 2 is 0.8 microns thick, the ink ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com