Tool for continuously cladding and processing small shaft workpieces by laser broadband

A broadband, cladding technology, applied in the direction of metal material coating process, coating, etc., can solve the problems of high processing cost, processing efficiency, low processing efficiency and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

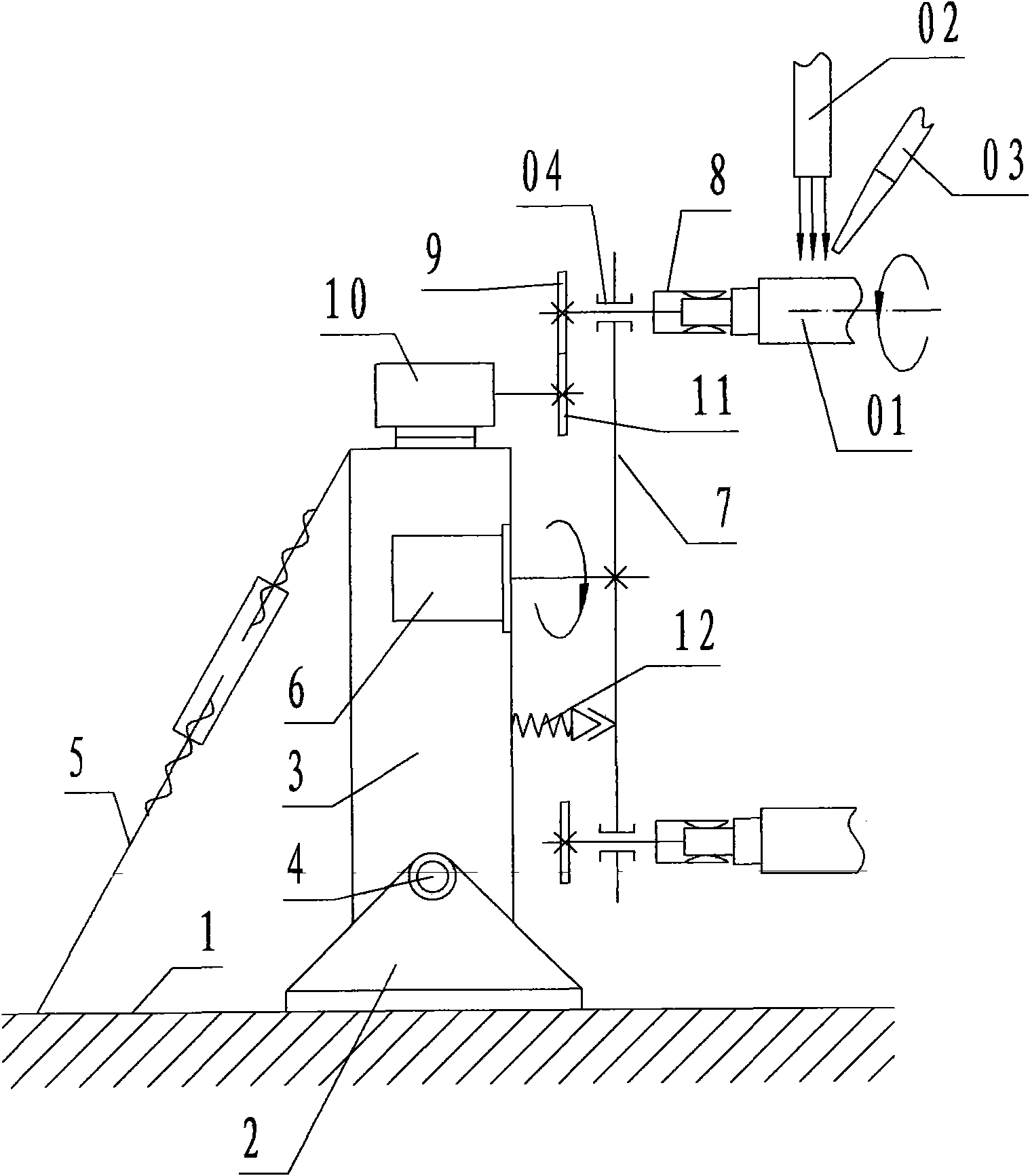

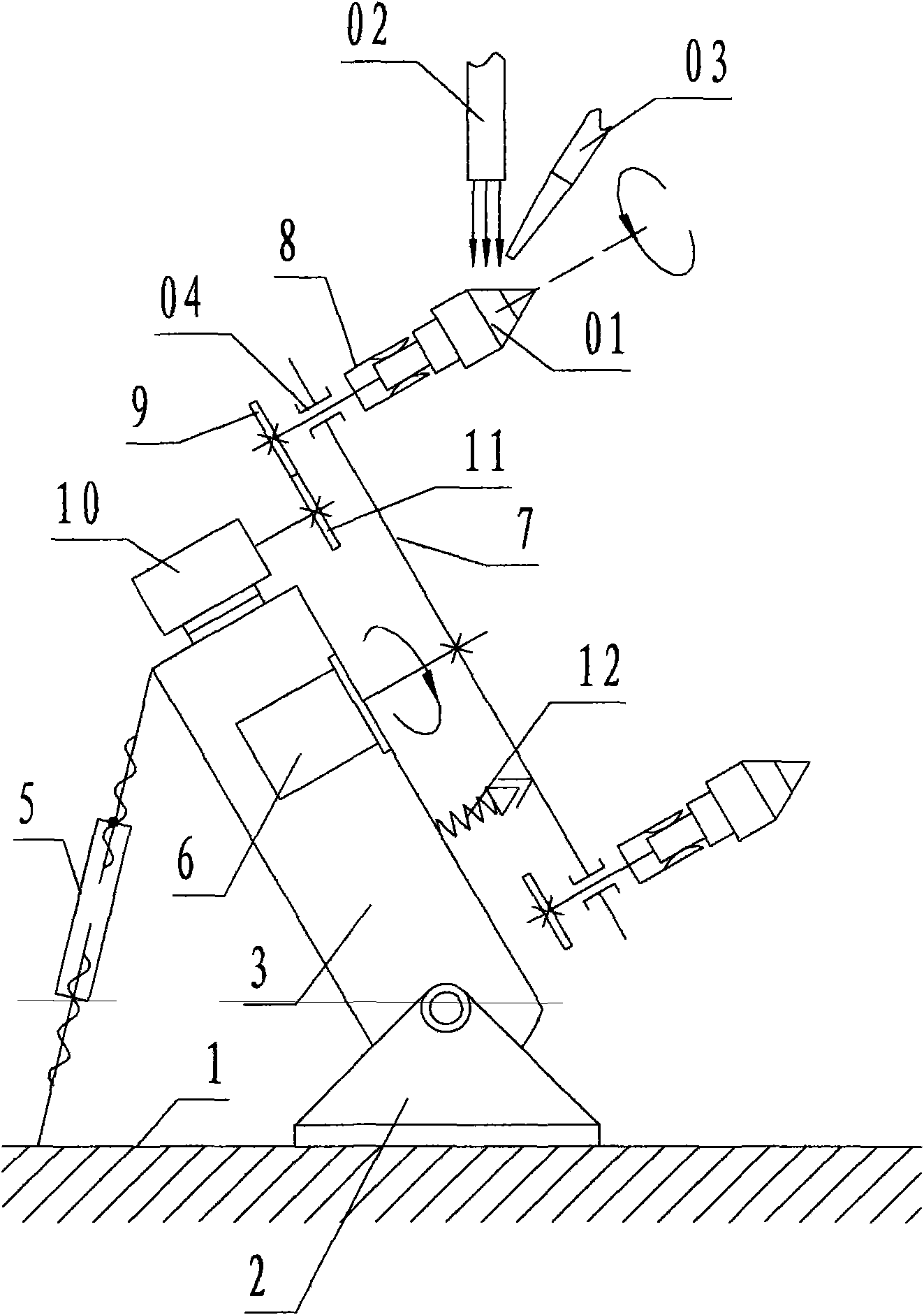

[0016] refer to figure 1 , figure 2 , a tooling device for continuous operation of laser broadband cladding processing small shaft workpieces of the present invention, including a machine base 1, a bracket base 2, a bracket 3, a rotating shaft 4, an adjusting screw 5, a turntable rotation driver 6, a turntable 7, and a clamper 8. Driven friction wheel 9, workpiece rotation driver 10, driving friction wheel 11, bead positioning pin 12, wherein: the machine base 1 is a rectangular frame base with a flat top welded by channel steel and steel plate, and the top There are rotating mortise joints and several screw holes on the flat surface; the support seat 2 is an open groove member with vertical walls on both sides welded by steel plate, and the upper center of the two vertical walls is respectively provided with the same vertical wall through the vertical wall surface. The shaft hole of the axis; the support 3 is a trough-shaped member with a wall frame on five sides welded by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com