Bearing assembly for machine table with magnetic load relieving mechanism

A bearing device, the technology of magnetic bearings, applied in the direction of bearings, bearings, shafts and bearings of rotary motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

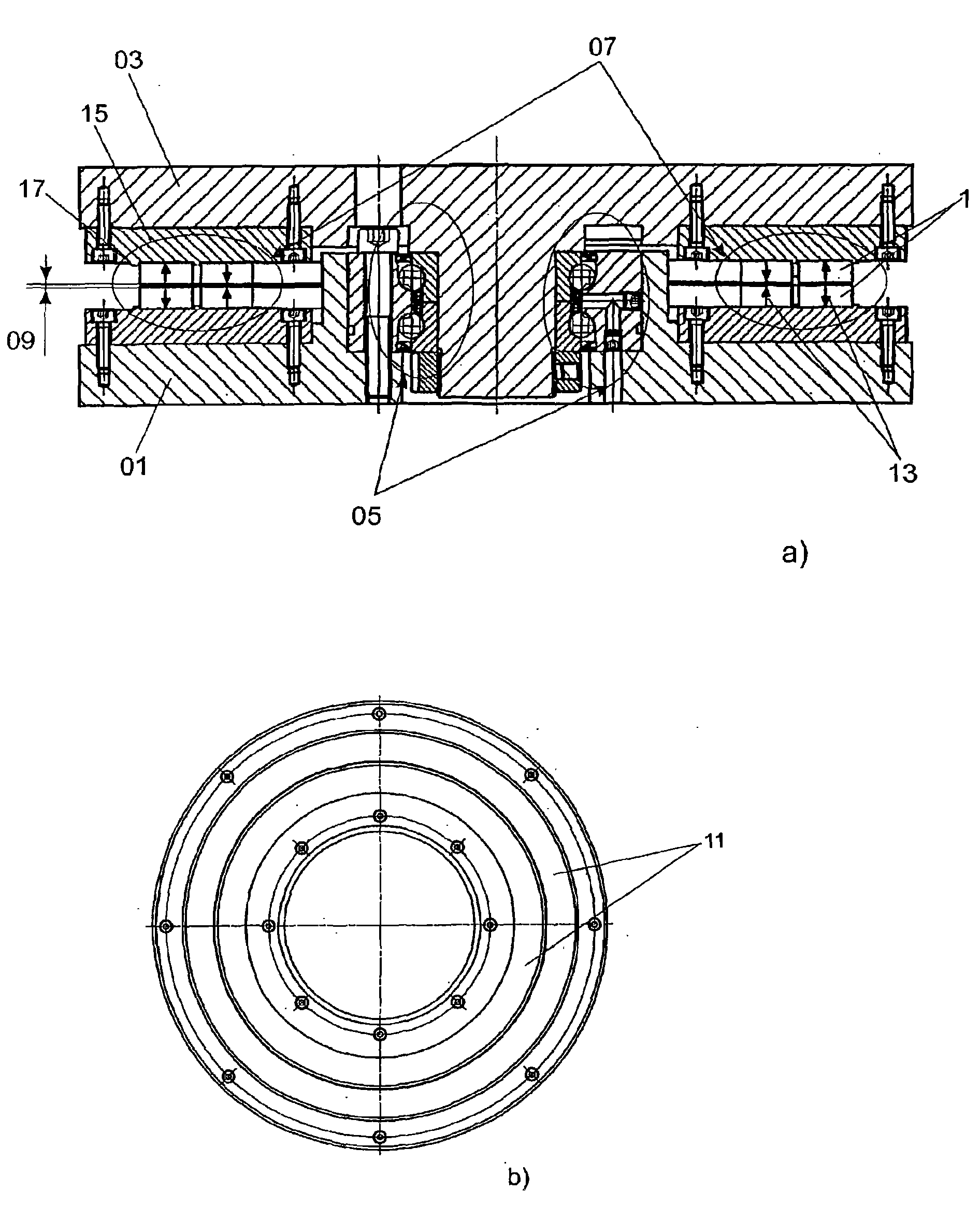

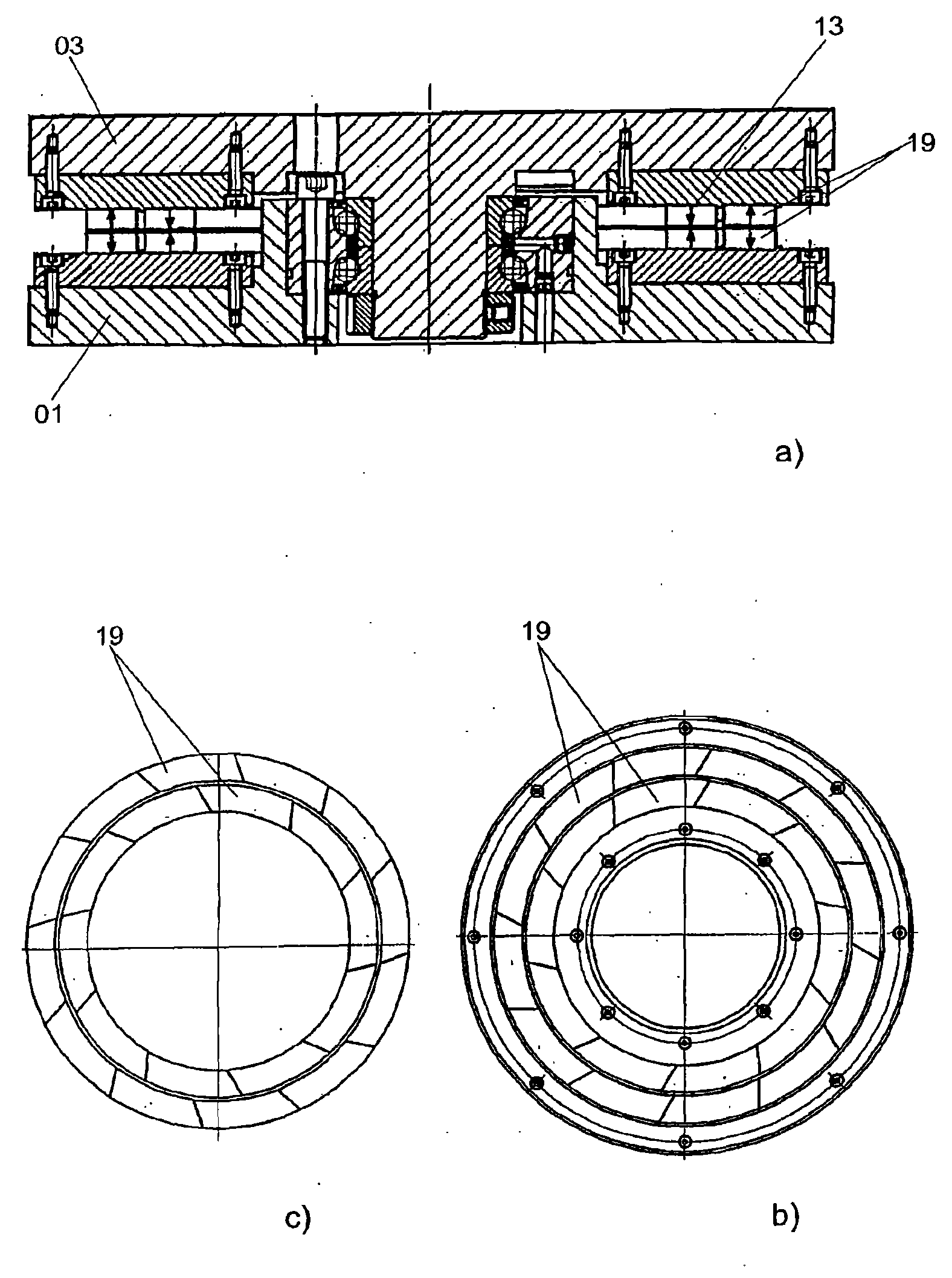

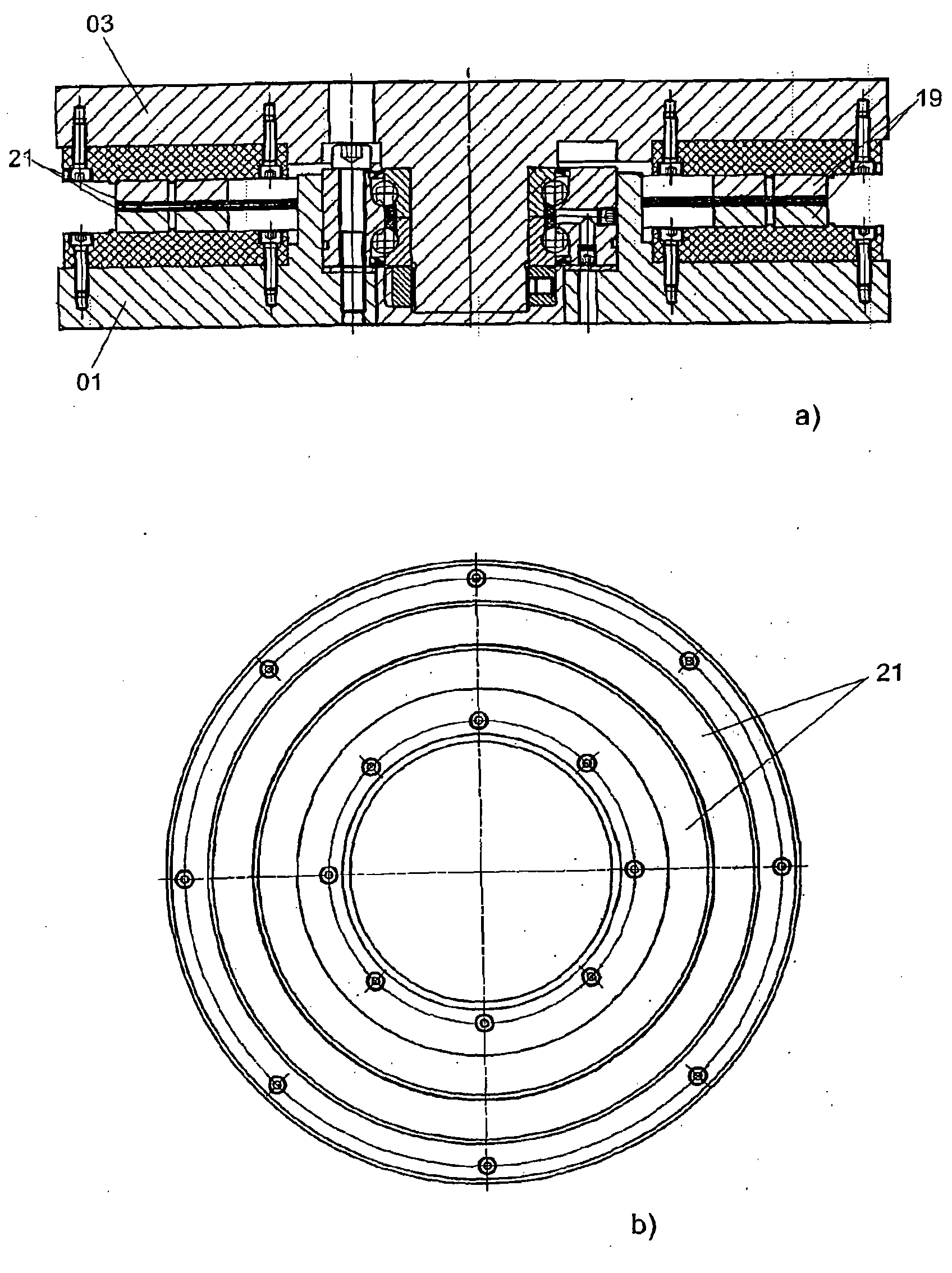

[0024] figure 1 a) shows a sectional view of a first embodiment of a bearing arrangement for a machine table with a stator 01 and a rotor 03 mounted movably relative to the stator. The support takes place via the rolling bearing 05 and the magnetic bearing 07 , which unloads the rolling bearing 05 by magnetic repulsion forces. The two component bearings are designed as swivel bearings, wherein a double row angular contact ball bearing is provided as rolling bearing 05 . As an alternative, cylindrical ball bearings or radial / axial roller-cylindrical bearings are preferably considered.

[0025] The rotor 03 is supported movably relative to the stator 01 via a rolling bearing 05 . The magnetic bearing 07 is arranged radially outside the rolling bearing 05, and has a stator permanent magnet group fixed on the stator and an opposite rotor permanent magnet group fixed on the rotor. The stator permanent magnet group and the rotor permanent magnet group pass through the air gap 09 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com