Railway full-automatic bearing press

A fully automatic, press-fitting machine technology, applied in metal processing, metal processing equipment, hand-held tools, etc., can solve the problems of unbalanced lifting of the wheel and axle, not ideal, etc., to achieve a wide range of press-fitting applications, improve performance, and ensure The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

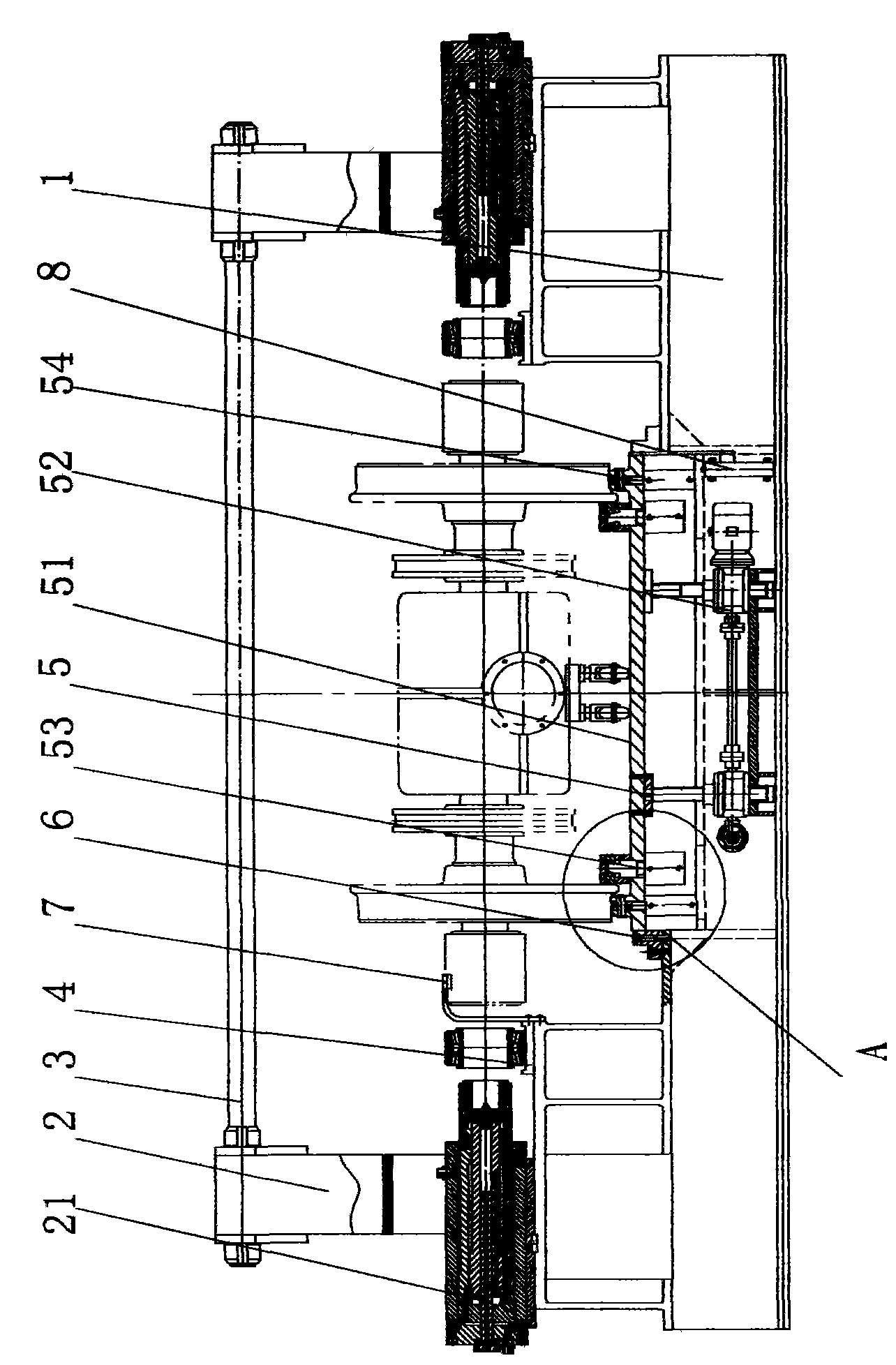

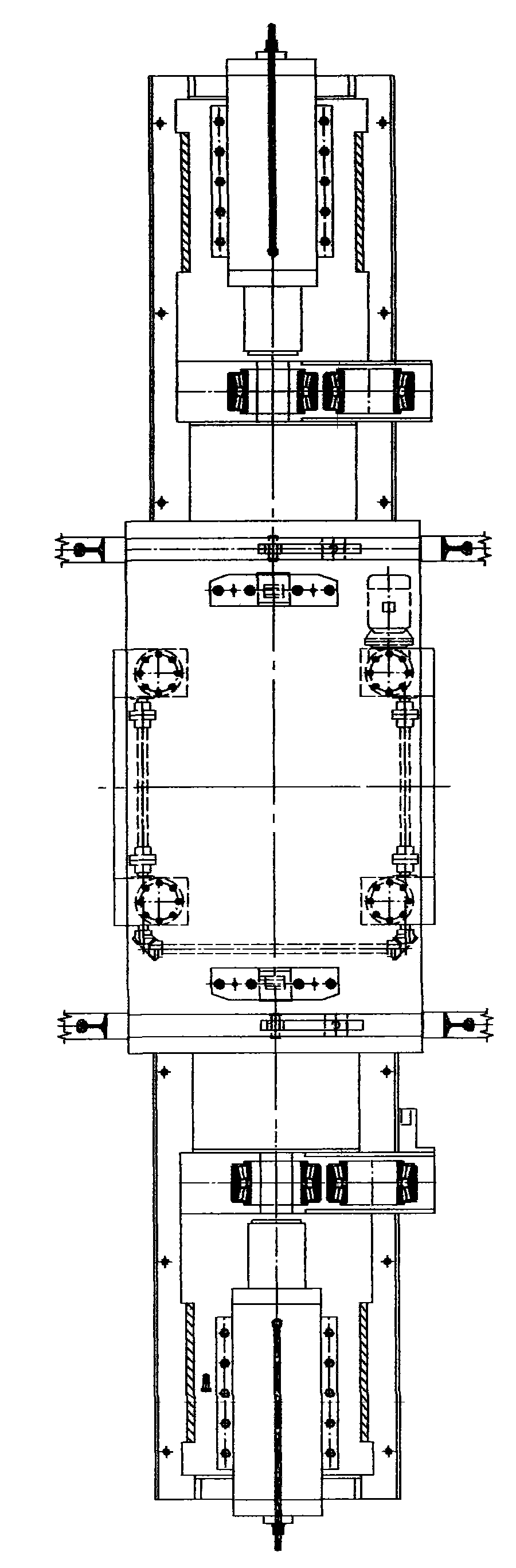

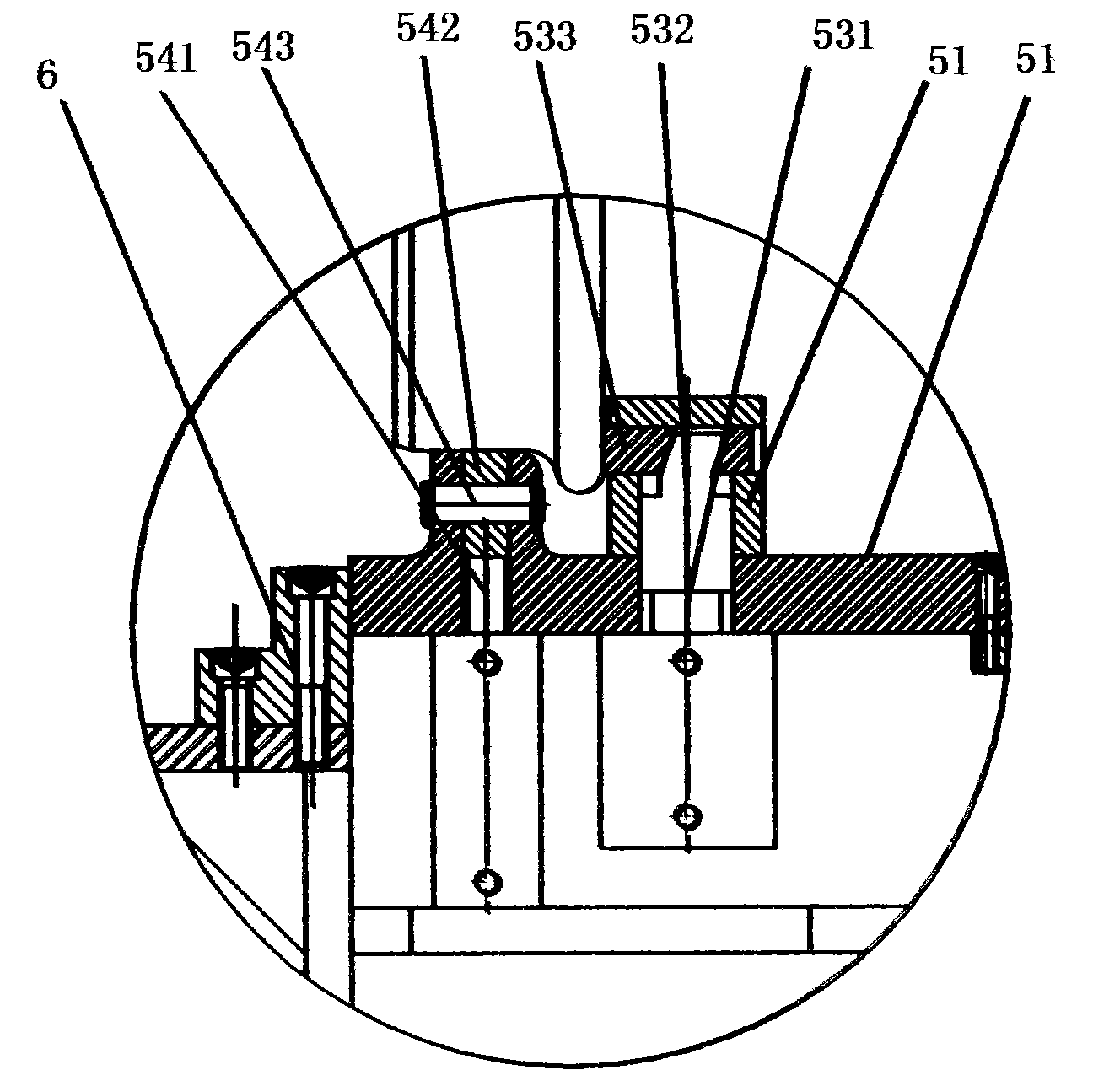

[0017] The present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 with figure 2 As shown, the present invention discloses a fully automatic bearing pressing machine for railways, which includes a base 1, left and right side frames 2 and pull rods 3, left and right main press-fitting combined oil cylinders 21, bearing bracket 4, hydraulic and electrical control systems, left and right side frames It is connected with the two sides of the base, and the top of the left and right side frames are connected by circular tie rods, so that the whole equipment forms a closed frame force structure. The left and right main press-fit combined oil cylinders are symmetrically installed in the left and right side frames. 1. There is an intelligent overall support, locking, and push wheel system 5 for wheelsets in the middle. It is equipped with an upper platform 51. An intelligent support lifting mechanism 52 is installed under the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com