Railway full-automatic bearing press

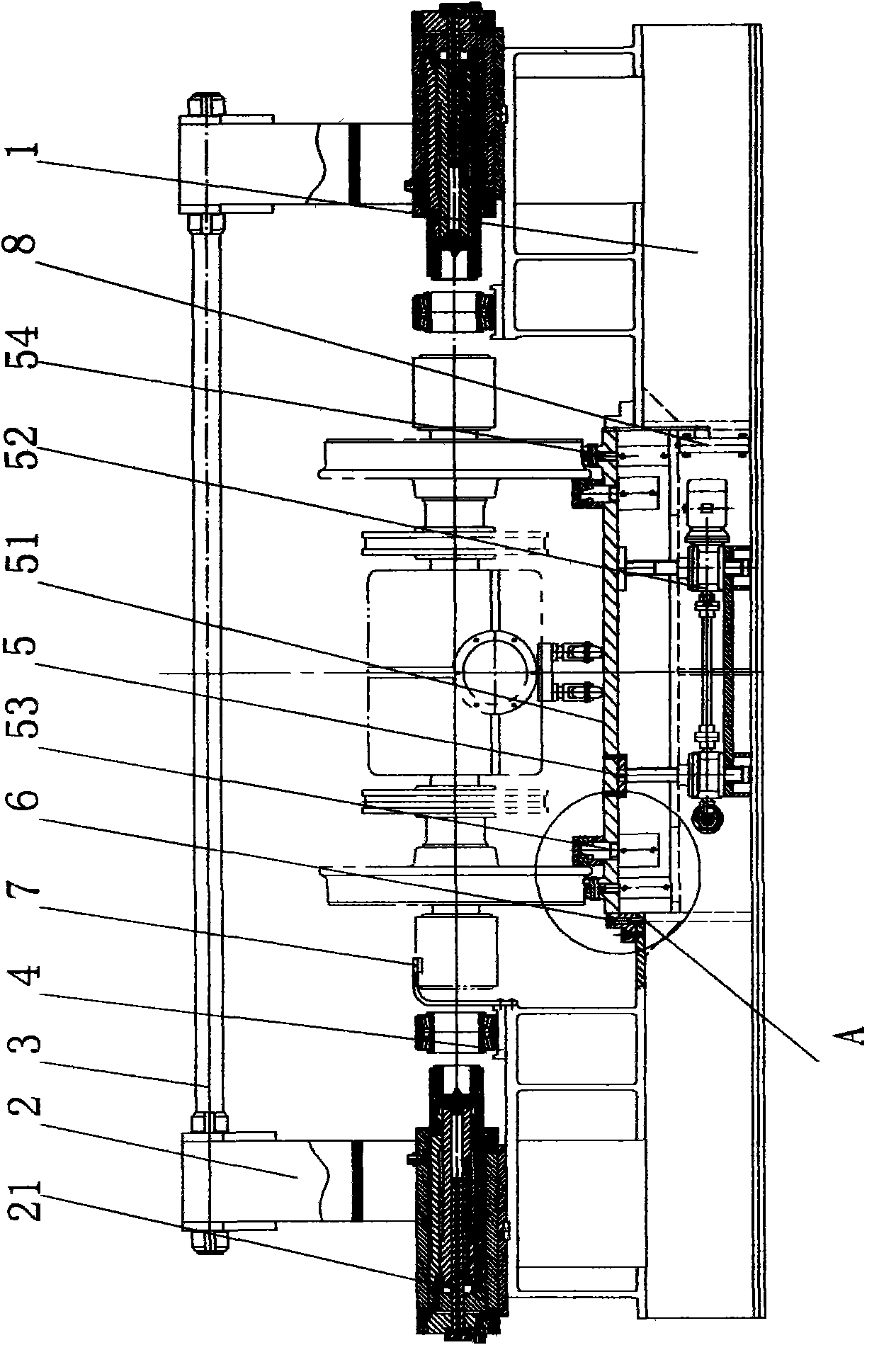

A fully automatic, press-fitting technology, used in metal processing, metal processing equipment, hand-held tools, etc., can solve the problems of inability to balance the axle and lift, not ideal, and achieve a wide range of press-fitting applications and avoid mutual interference. , Accurate effect of pressing curve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

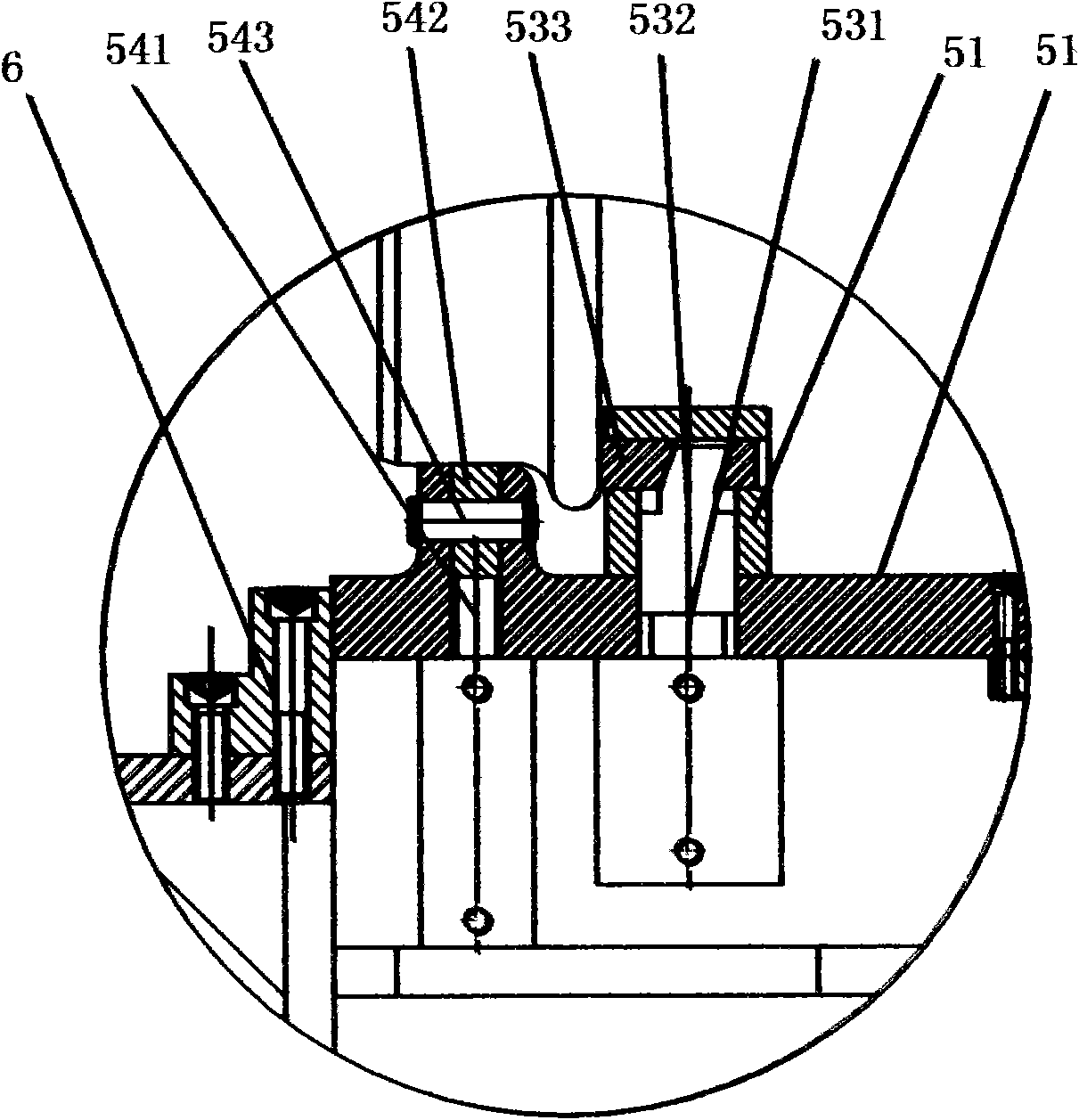

[0019] The locking device 53 is equipped with a tightening block 532, lock wheel block 533 in front of the oil cylinder piston piston 531, and installed in the support of the branch 534.

[0020] The push -wheel oil cylinder device 54 is equipped with a push wheel block 542 before the oil cylinder piston 541, and the sales axis 543 cross the push block.

[0021] The measuring device 8 is installed on the upper installation of a displacement sensor, and the activity head of the displacement sensor is connected to the upper platform.

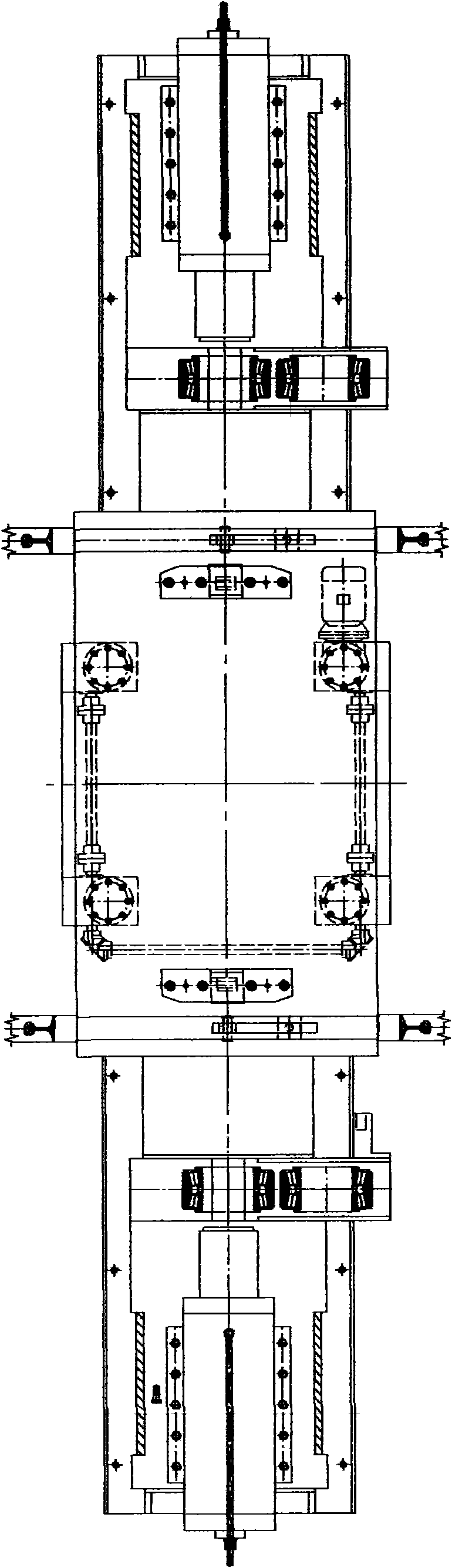

[0022] The main pressure combination of the main pressure combination of the present invention is the same, and the three -compound oil cylinder structure is adopted.During the bearing pressure process, the constant top force of the small hydraulic congestion is to ensure accurate positioning, and the rotating structure of the medium piston prestressing and the front -end front -end can ensure the plane contact of the axial bearing.

[0023] In order ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com