Device for preparing carbon nano tube by arc process

A carbon nanotube and arc method technology, which is applied to the device field in the field of nanotechnology, can solve the problems of amorphous carbon and other impurities, the purity of carbon nanotubes is not high, and the purity of products is reduced, so as to achieve a suitable growth environment and optimize growth. conditions, the effect of improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

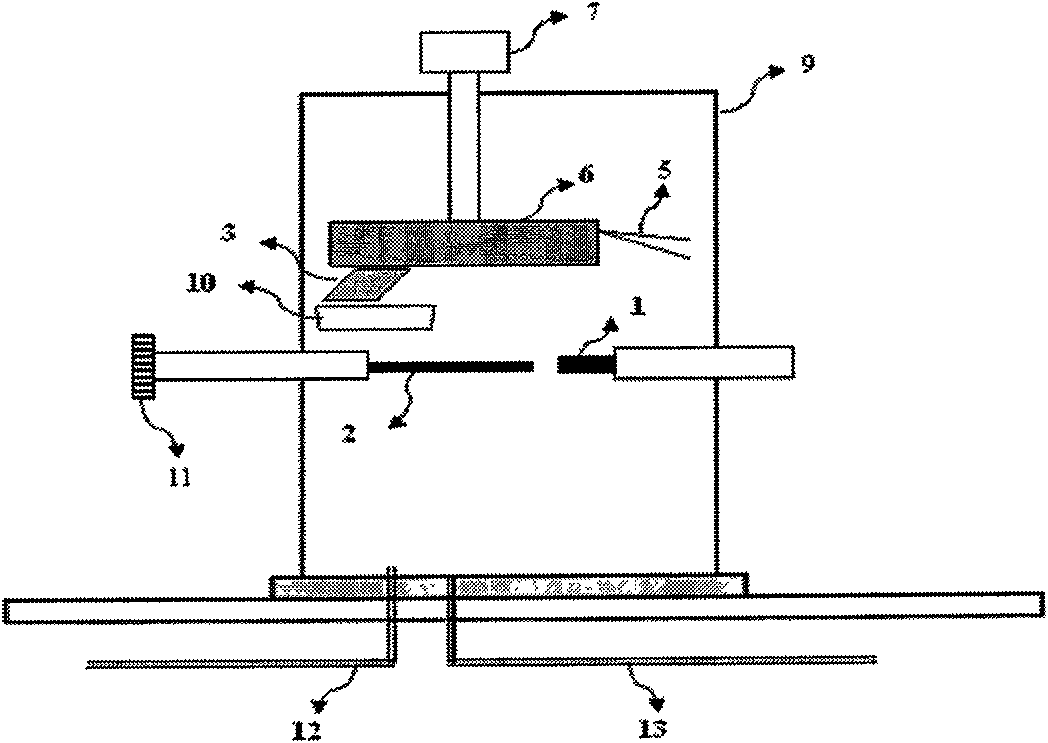

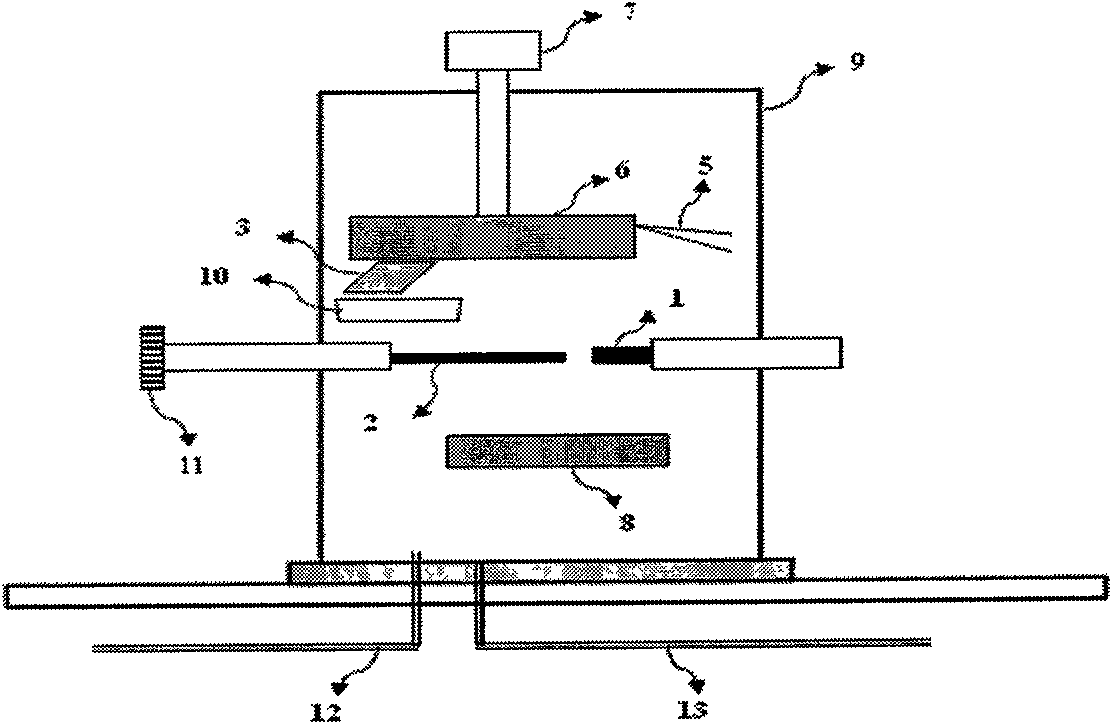

[0022] The preparation device of this embodiment is as image 3 As shown, it includes: cathode graphite rod 1, anode graphite rod 2, scraper 3, thermocouple 5, collection turntable 6, drive motor 7, fixed graphite disk 8, reaction chamber 9, carbon nanotube collection box 10, anode graphite Rod propulsion device 11, air inlet 12, air extraction port 13, wherein, anode graphite rod 2 diameters are 6mm, long 80mm; Anode graphite rod 2 contains Ni / Co / Fe catalyst (the mass ratio of Ni: Co: Fe 5: 1 : 1, graphite accounts for 95% of the total mass of the anode graphite rod); the anode graphite rod 2 is fixed on the anode graphite rod propelling device 11; the cathode graphite rod 1 is a high-purity graphite rod, and its diameter is 8mm, and the length is 300mm; the anode graphite rod It is arranged opposite to the cathode graphite rod, leaving a distance of 3 mm in the middle; the fixed graphite disc 8 is located 40 mm below the anode graphite rod 2 and the cathode graphite rod 1; ...

Embodiment 2

[0029] The preparation device of this embodiment includes: cathode graphite rod 1, anode graphite rod 2, reaction chamber 9, anode graphite rod propelling device 11, air inlet 12, air extraction port 13, scraper 3, thermocouple 5, collection turntable 6. Drive motor 7, carbon nanotube collection box 10. Among them, the anode graphite rod 2 has a diameter of 6 mm and a length of 80 mm; the anode graphite rod 2 is made of Ni, Y 2 o 3 , graphite powder as raw material (Ni and Y 2 o 3The role of catalyst), according to the molar ratio of Ni: Y: C is 4.2: 1: 94.8 to carry out batching, after mixing uniformly press rod molding; Anode graphite rod 2 is fixed on the anode graphite rod propelling device 11; Cathode graphite rod 1 It is a high-purity graphite rod with a diameter of 8 mm and a length of 300 mm; the anode graphite rod and the cathode graphite rod are arranged opposite to each other, leaving a distance of 2 mm in the middle; Cut, the carbon nanotube collection box 10 i...

Embodiment 3

[0036] The preparation device of this embodiment includes: cathode graphite rod 1, anode graphite rod 2, reaction chamber 9, anode graphite rod propelling device 11, air inlet 12, air extraction port 13, scraper 3, thermocouple 5, collection turntable 6. Drive motor 7, carbon nanotube collection box 10. Among them, the anode graphite rod 2 has a diameter of 6 mm and a length of 80 mm; the anode graphite rod 2 is made of Ni, Y 2 o 3 , CeO 2 , graphite powder as raw material (Ni, Y 2 o 3 , CeO 2 The role of catalyst), according to the molar ratio of Ni: Y: Ce: C is 4.2: 1: 0.1: 94.7 to carry out the batching, after mixing evenly, the rod is formed; the anode graphite rod 2 is fixed on the anode graphite rod propulsion device 11; The cathode graphite rod 1 is a high-purity graphite rod with a diameter of 8mm and a length of 300mm; the anode graphite rod and the cathode graphite rod are arranged opposite to each other, leaving a distance of 2mm in the middle; the collection t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com