Electrode wire for slow-moving wire electric discharge machining with carbon on the surface layer and preparation method thereof

A technology of electrode wire and slow wire walking, which is applied in the direction of electric processing equipment, electrode manufacturing, metal processing equipment, etc., to achieve uniform discharge intensity, increase discharge frequency, and improve processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

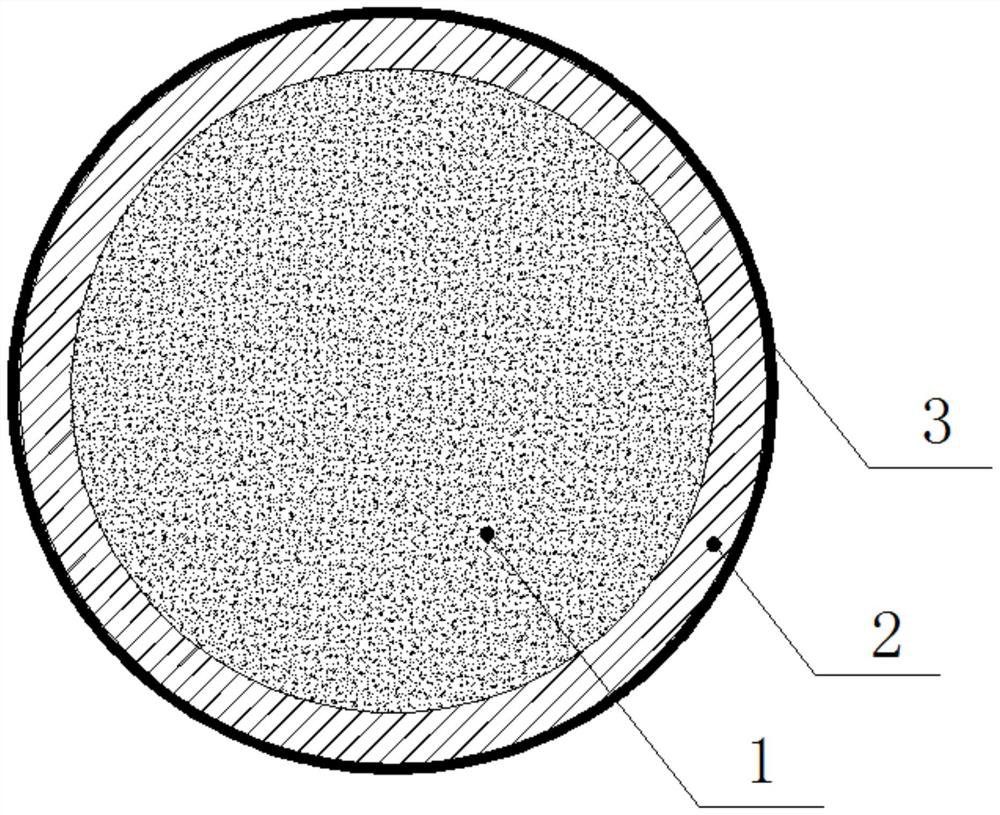

Image

Examples

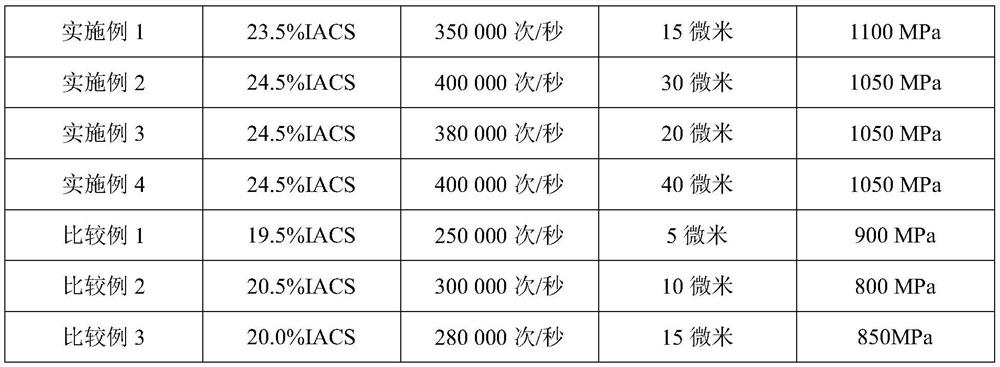

Embodiment 1

[0037] 1. Prepare brass grades H65 and wire blanks with a diameter of Φ1.2mm. After electroplating pretreatment, carry out alkali cleaning and pickling. After the surface of the wire blanks is cleaned, enter the electroplating tank. The bath liquid is zinc sulfate 1000g / L, CHO A mixed solution of 20g / L of organic matter, 15g / L of aluminum salt and 15g / L of potassium salt, the production speed is set to 100m / min, the electroplating current is 900A, the voltage is 8V, and the coating thickness of the final electroplating wire billet is 10 microns. The surface roughness of the blank is Ra 0.12 μm.

[0038] 2. Carry out the carbon precipitation reaction in the annealing furnace with 97% nitrogen content, the reaction temperature is 150°C, the reaction time is 10 hours, the furnace temperature is 50°C, and the uniformity in the furnace is ±10 ℃.

[0039] 3. The wire blank after the carbon precipitation reaction is cleaned with aviation kerosene, stretched to Φ0.6mm after cleaning,...

Embodiment 2

[0045] 1. Prepare brass grades H65 and wire blanks with a diameter of Φ1.2mm. After electroplating pretreatment, carry out alkali cleaning and pickling. After the surface of the wire blanks is cleaned, enter the electroplating tank. The bath liquid is zinc sulfate 1000g / L, CHO A mixed solution of 20g / L of organic matter, 15g / L of aluminum salt and 15g / L of potassium salt, the production speed is set to 100m / min, the electroplating current is 2000A, the voltage is 9V, and the coating thickness of the final electroplating wire billet is 20 microns. The surface roughness of the blank is Ra 0.15 μm.

[0046] 2. Carry out the carbon precipitation reaction in the annealing furnace with 97% nitrogen content, the reaction temperature is 750°C, the reaction time is 3 hours, the furnace temperature is 80°C, and the uniformity in the furnace is ±10 ℃.

[0047] 3. The wire billet after the carbon precipitation reaction is cleaned with aviation kerosene, and drawn to the specification of ...

Embodiment 3

[0053] 1. Prepare brass grades H65 and wire blanks with a diameter of Φ1.2mm. After electroplating pretreatment, carry out alkali cleaning and pickling. After the surface of the wire blanks is cleaned, enter the electroplating tank. The bath liquid is zinc sulfate 1000g / L, CHO A mixed solution of 20g / L of organic matter, 15g / L of aluminum salt and 15g / L of potassium salt, the production speed is set to 100m / min, the electroplating current is 900A, the voltage is 8V, and the coating thickness of the final electroplating wire billet is 10 microns. The surface roughness of the blank is Ra 0.12 μm.

[0054] 2. Carry out carbon precipitation reaction in the annealing furnace with 97% nitrogen content in the plated wire blank. The reaction temperature is 750°C, the reaction time is 10 hours, the furnace temperature is 80°C, and the uniformity in the furnace is ±10 ℃.

[0055] 3. The wire billet after the carbon precipitation reaction is cleaned with aviation kerosene, and drawn to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com