Discharge gap control system and control method for wire electric discharge cutting single crystal silicon

An EDM wire and discharge gap technology, applied in circuits, manufacturing tools, electric machining equipment, etc., can solve problems such as relatively few research strategies and algorithms for real-time adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

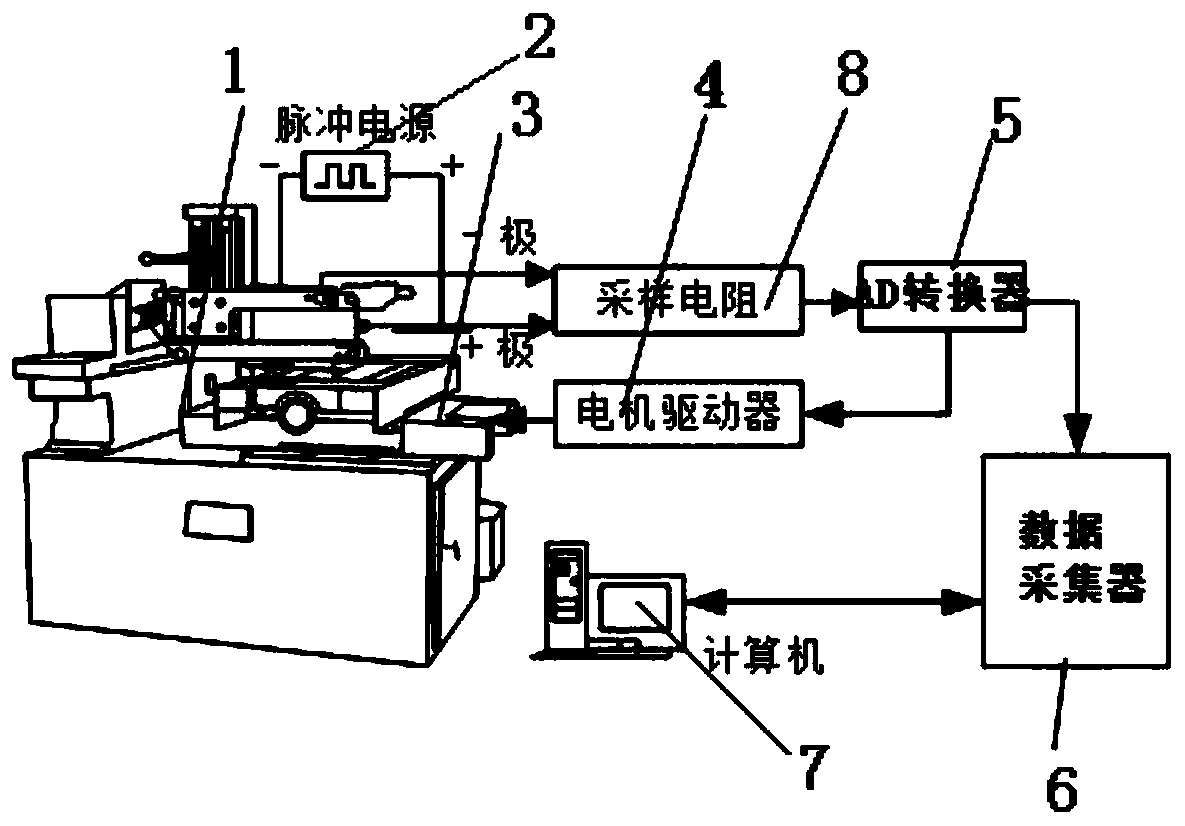

[0087] The present invention is a discharge gap control system for wire electric discharge cutting single crystal silicon, such as figure 1 As shown, it includes a DK7740 wire-cut electric discharge machine tool 1 and a pulse power supply 2. The monocrystalline silicon workpiece and the cutting wire of the wire-cut electric discharge machine tool 1 are respectively connected to the positive pole and the negative pole of the pulse power supply 2, and the single-crystal silicon workpiece of the wire-cut electric discharge machine tool 1 A YK86HB80-04A-type stepping motor 3 and a YKA2608MC-type motor driver 4 are sequentially installed in the feeding direction of the crystalline silicon workpiece, and the motor driver 4 is connected to a NI-USB 6251 multifunctional data collector 6 and a computer through an AD converter 5 in turn. 7. Sampling re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com