Surface hardening method for tooth surface of large-sized bevel wheel

A technology of surface quenching and helical gears, which is applied in the direction of quenching devices, furnace types, furnaces, etc., can solve the problems of inability to achieve quenching, and achieve the effect of simple structure, meeting the requirements of quenching, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

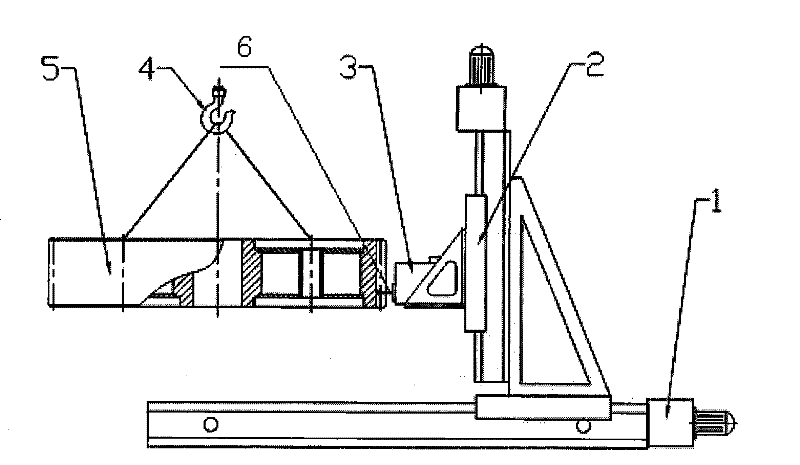

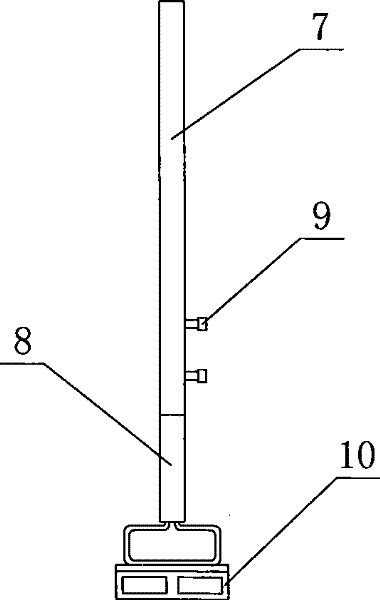

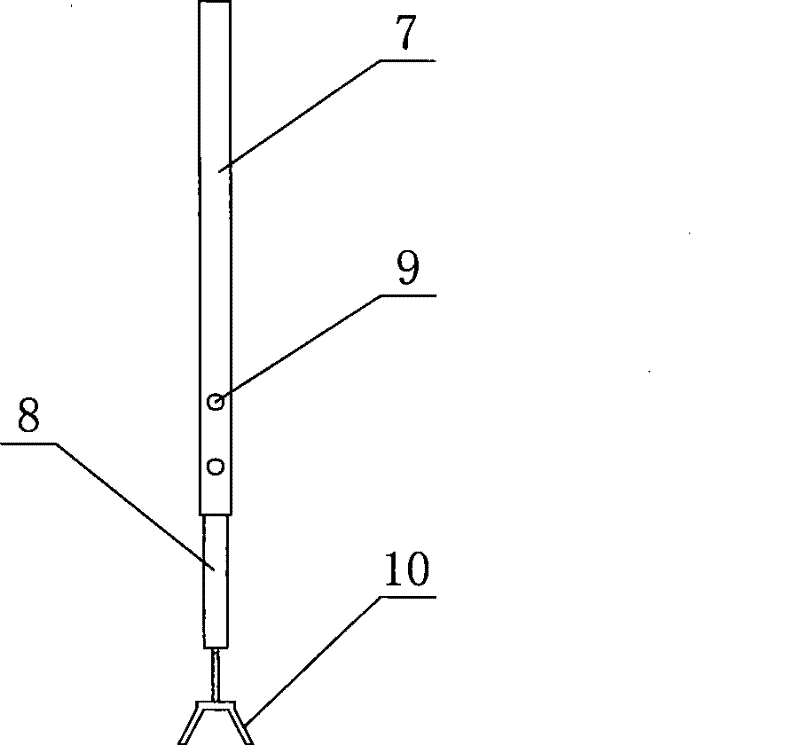

[0019] The technical contents of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0020] The surface quenching of the gear tooth surface must adopt the continuous quenching method. For spur gears, the quenching equipment only needs to have the function of moving along the tooth surface. For the continuous quenching of helical gears, not only does the quenching equipment have the function of moving along the tooth surface, but also the gear needs to make circular motion along the axis. The speeds of the two must cooperate with each other to realize the quenching of the tooth surface.

[0021] The invention adds a device to the original quenching equipment, and the device can realize the circular motion of the helical gear along the axis.

[0022] The specific technical scheme is as follows:

[0023] A method for quenching the tooth surface of a large helical gear. The method adopts a movable medium-frequency power supply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com