Grain condition detecting rod

A technology for detecting rods and grain conditions, which can be used in the fields of catching or killing insects, sampling devices, animal husbandry, etc. It can solve the negative pressure environment where it is difficult to extract pests, cannot continuously and reliably extract pests, and lower the space of insect traps Large and other problems, to achieve the effect of improving economic and social benefits, simple structure, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

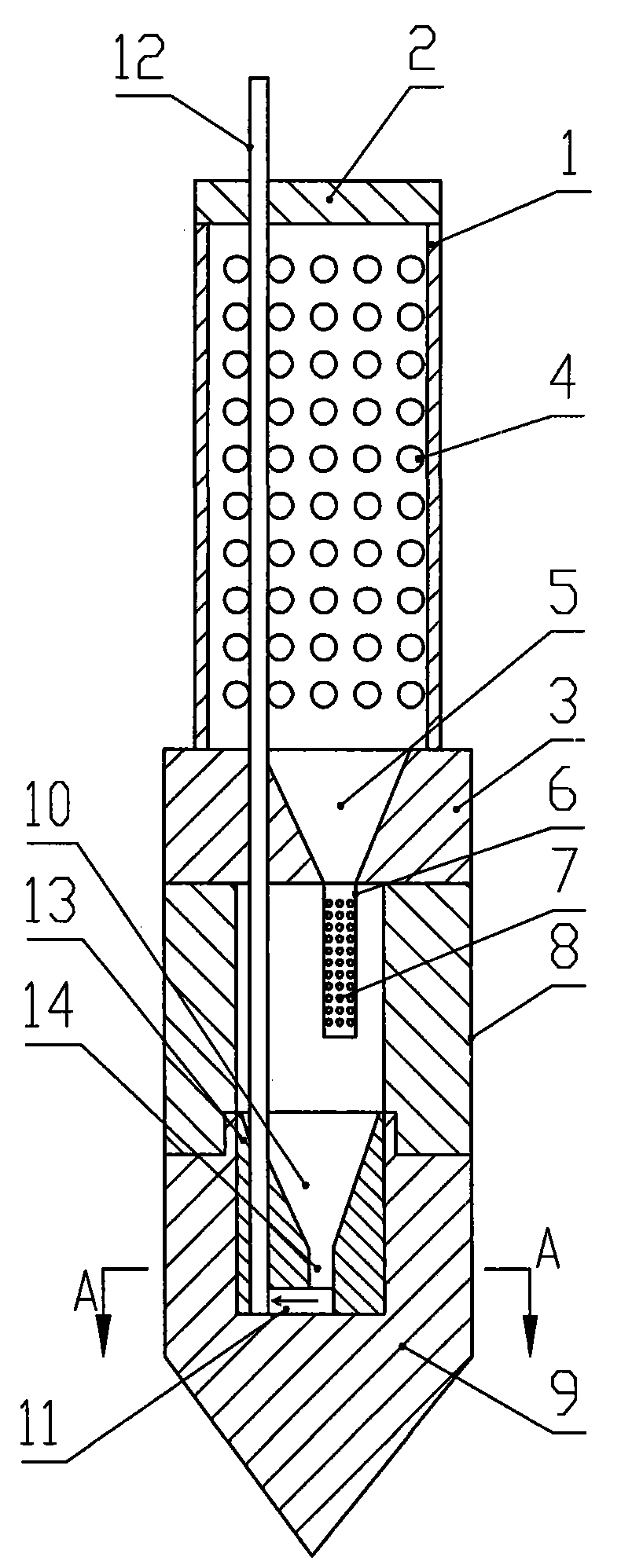

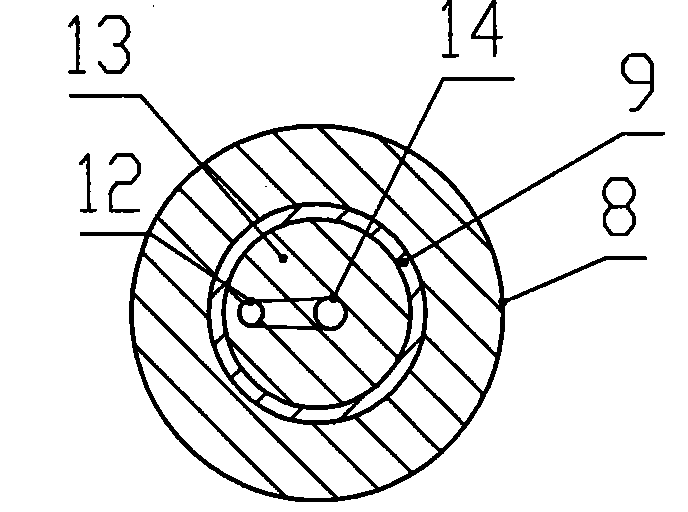

[0029] Such as figure 1 , 2 As shown, the present invention includes an insect trap rod 1 , the upper end of the insect trap rod 1 is connected with a plug 2 , and the lower end of the insect trap rod 1 is connected with a joint 3 . Insect trap rod 1 is a hollow rod, evenly distributed with trap holes 4 on the rod, and the center line of trap holes 4 is inclined downward with the axis of trap rod 1 to have an angle, so that dust and impurities are difficult to enter when pulling out. The diameter of the trap hole 4 is smaller than the particle size of the grain but larger than the size of the pests to be captured.

[0030] A funnel 5 is provided in the middle of the joint 3, and the wall of the funnel 5 is smooth to prevent pests from climbing up along the wall. The lower end of the funnel 5 is fixedly connected with an impurity separation pipe 6, the impurity separation pipe 6 is hollow and sealed at the bottom, and a number of separation holes 7 are evenly arranged on the ...

Embodiment approach 2

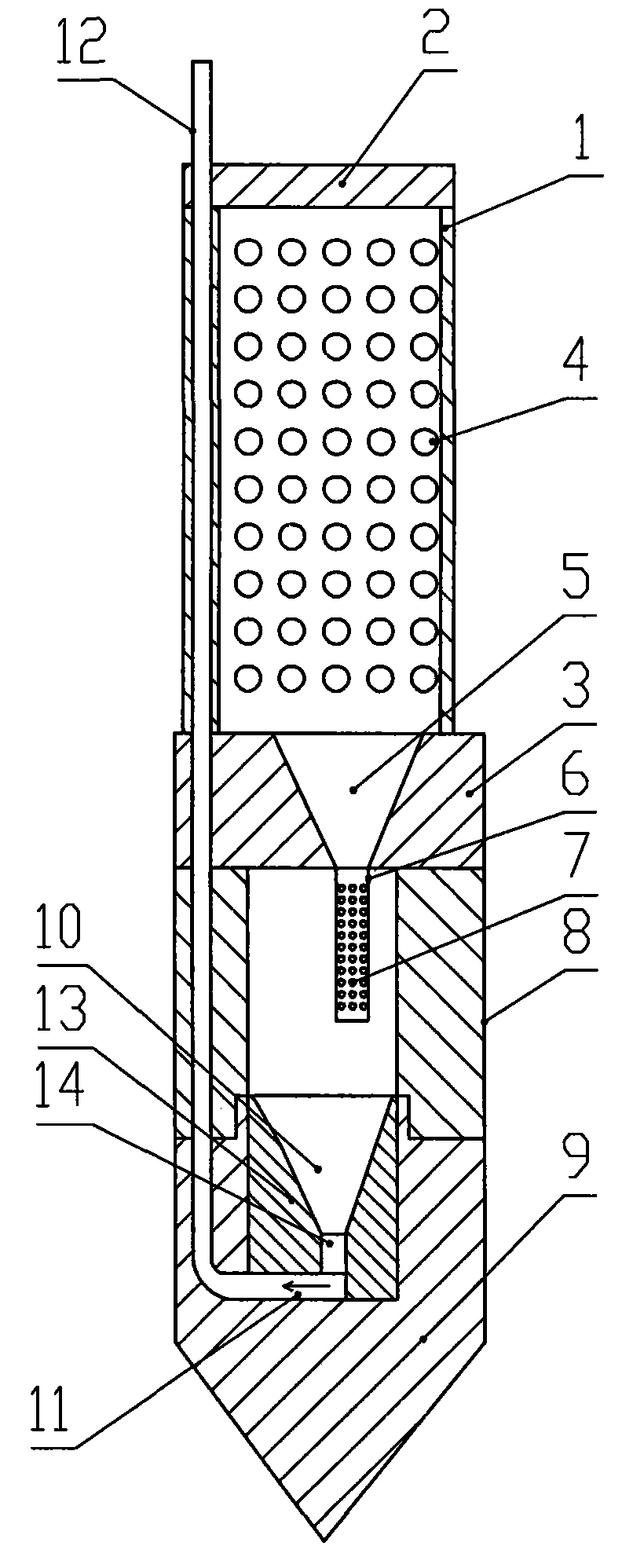

[0034] Such as image 3 As shown, the difference from the first embodiment is that the insect extraction pipe 12 passes through the side walls of the insect attracting rod 1 and the connecting rod 8 in sequence, the lower end of the insect extraction pipe 12 is bent to the right, and directly connects with the vertical pipe 14. The funnel 10 is connected. A bent section of pipeline forms the insect collecting space 11 instead of being formed by the insect collecting device 13 and the cone head 9 .

Embodiment approach 3

[0036] Such as Figure 4 As shown, the difference from Embodiment 1 is that the insect pumping tube 12 is arranged outside the insect trap rod 1, and no longer passes through the plug 2, the insect trap rod 1, the joint 3, the connecting rod 8 and the funnel 10, and finally Connect with Bug Space 11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com