Constant temperature insulation system for thermal conductivity gas detection

A gas detection and thermal conductivity technology, which is applied in the direction of material resistance, can solve the problems of low sensitivity, poor detection accuracy of thermal conductivity sensors, and large temperature drift, and achieve the effect of overcoming measurement temperature drift and improving accuracy and sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

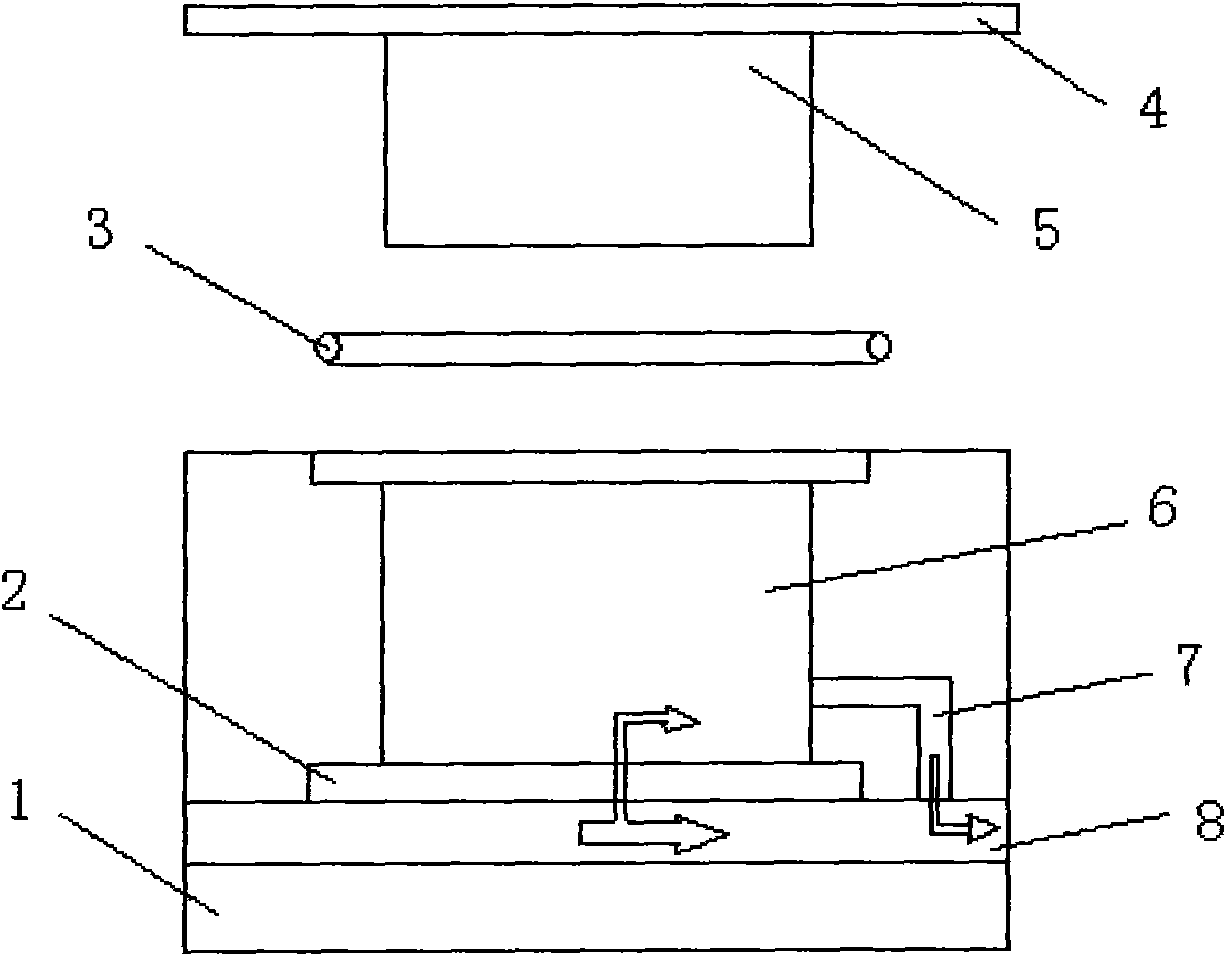

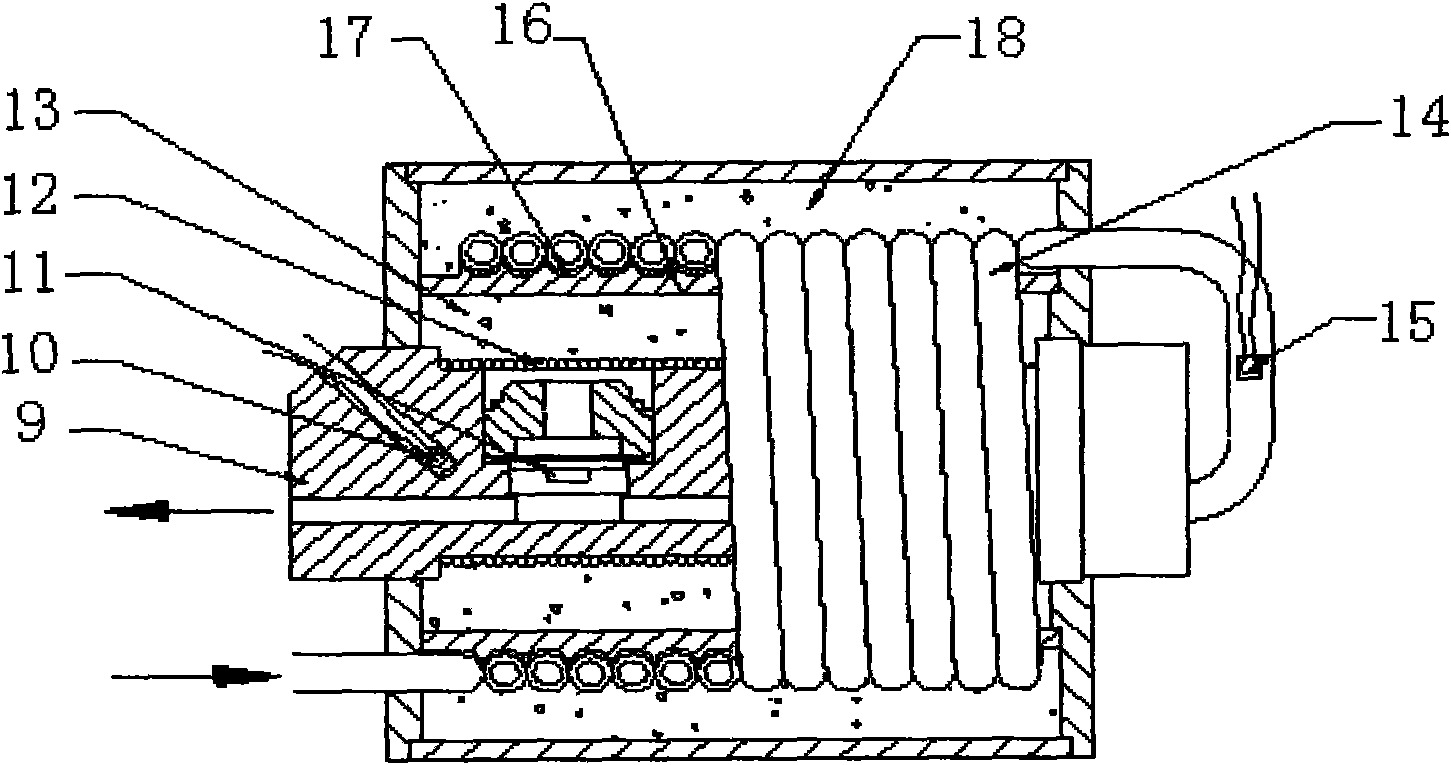

[0037] A constant temperature and heat insulation system for thermal conductivity sensor gas concentration detection, which is composed of a thermal conductivity sensor constant temperature unit and an air duct constant temperature unit. The thermal conductivity sensor constant temperature unit consists of a gas conduction chamber 9 and a thermal conductivity sensor fixed in the gas conduction chamber 9 11 and an air conduction chamber heating and temperature control system. The air conduction chamber 9 in the constant temperature unit of the thermal conductivity sensor is made of copper material, and the resistance wire 12 that can adjust the voltage at both ends is tightly wound on it for heating. The air conduction chamber 9 The platinum resistor 10 monitors the temperature in the chamber in real time, and the outer periphery of the air guide chamber is wrapped with polyurethane foam material to form a heat insulating layer 13. The air guide tube constant temperature unit is ...

Embodiment 2

[0040] A constant temperature and heat insulation system for gas concentration detection with a thermal conductivity sensor is basically the same as that of Embodiment 1, except that the thermal conductivity sensor constant temperature unit and the air duct constant temperature unit are two independent unit modules connected together through pipelines.

Embodiment 3

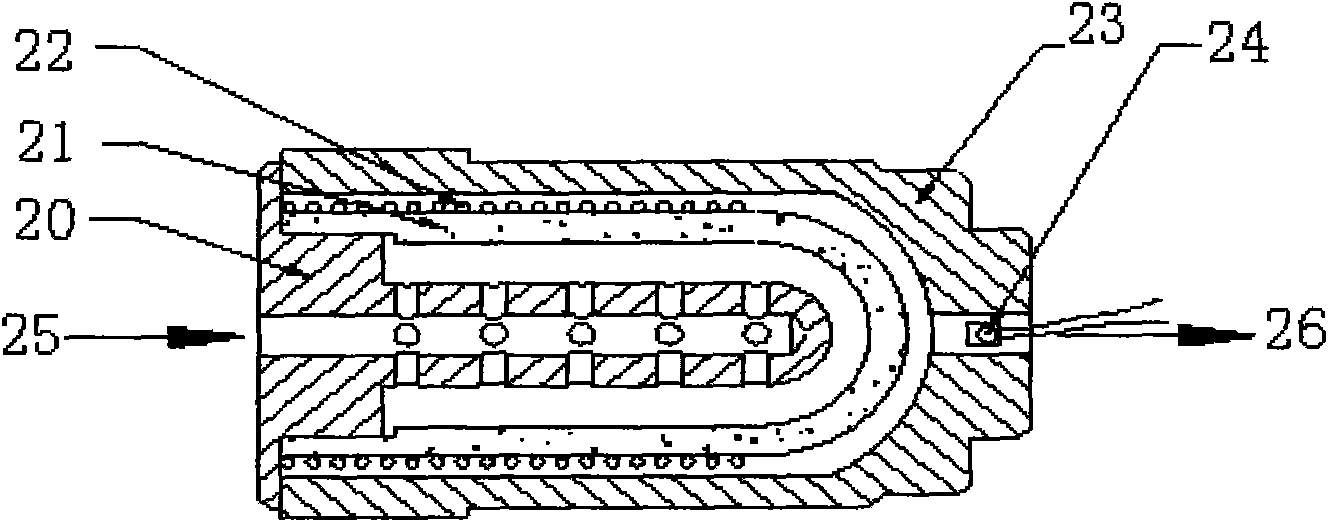

[0042] A constant temperature and adiabatic system for gas concentration detection with a thermal conductivity sensor, including an air duct constant temperature unit, such as image 3 As shown, the air duct constant temperature unit directly heats a U-shaped tubular filter, which is filled with copper powder, and the tubular filter has a very small ventilation hole; the gas enters from the inside of the U-shaped tubular filter and flows through the filter When it is heated, it reaches the outside of the filter and collects, and is in full contact with the thermal conductivity sensor to detect the gas concentration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com