Column temperature monitoring apparatus and chromatographic apparatus

A technology for monitoring equipment and chromatographic columns, applied in the field of chromatographic equipment, can solve the problems of insufficient pre-heating, insufficient pre-heating, and reduced analysis accuracy, and achieve the effects of consistent analysis conditions, improved accuracy, and improved analysis accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

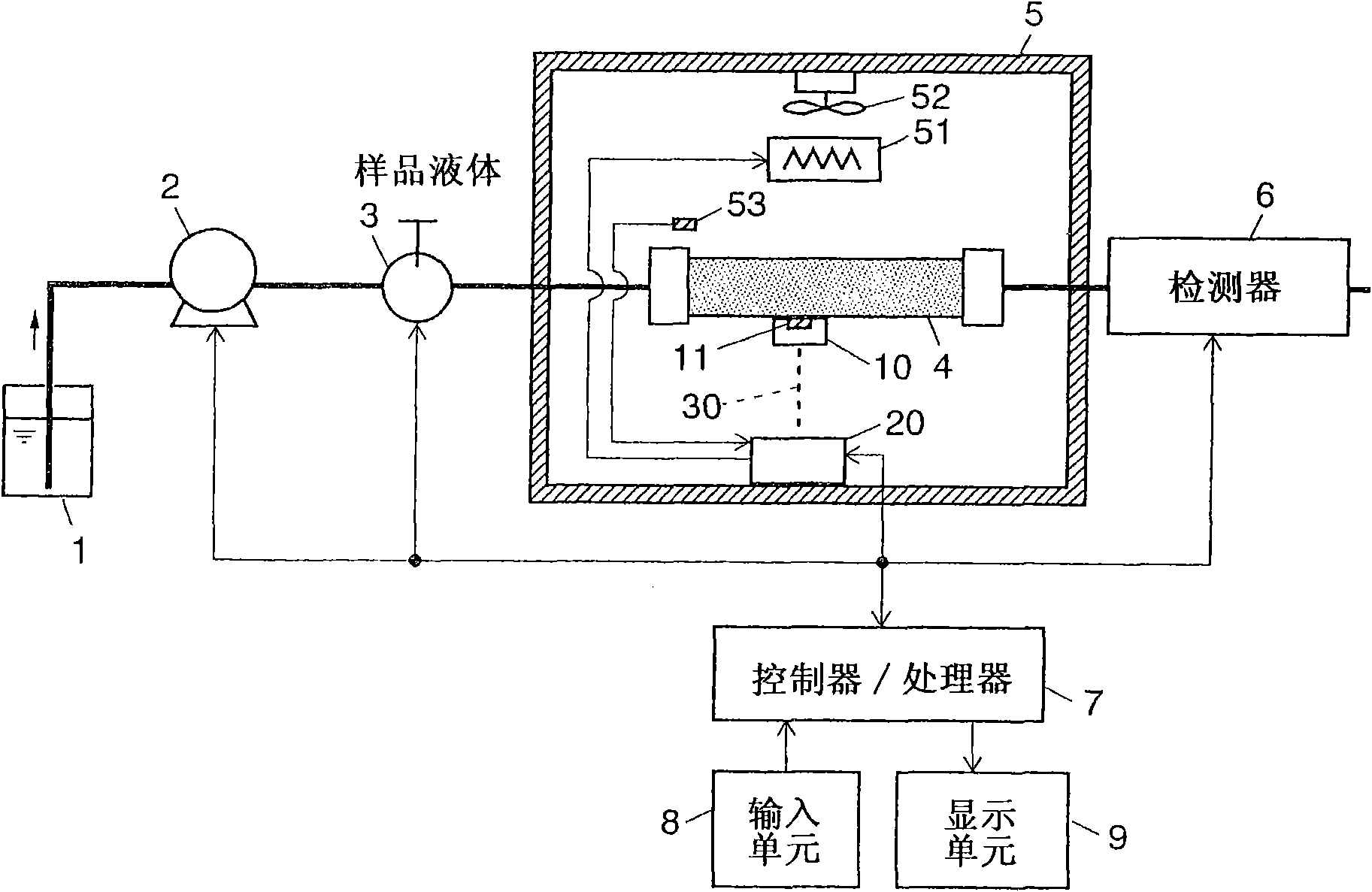

[0062] A liquid chromatography (LC) apparatus using a column temperature monitoring apparatus according to an embodiment of the present invention will be described with reference to the accompanying drawings. figure 1 It is a configuration diagram of the main part of the LC device.

[0063] In the LC apparatus, a liquid sending pump 2 sucks the mobile phase held in a mobile phase container 1 and sends the mobile phase to a column 4 through an auto sampler 3 at a constant flow rate. The auto sampler 3 includes a syringe, and selects a specific sample from various samples that have been prepared in advance, and injects the sample into the mobile phase. The injected sample carried by the mobile phase is introduced into the chromatography column 4 . While passing through column 4, the sample is briefly separated and eluted from there. As described above, the chromatography column 4 is contained in the constant temperature bath 5 which can be controlled at a constant temperature....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com