Optical fiber cabling die

A cabling and optical fiber technology, applied in the direction of fiber mechanical structure, etc., can solve problems such as bare fiber processing, avoid damage or breakage, high assembly accuracy, and facilitate accurate threading and guidance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

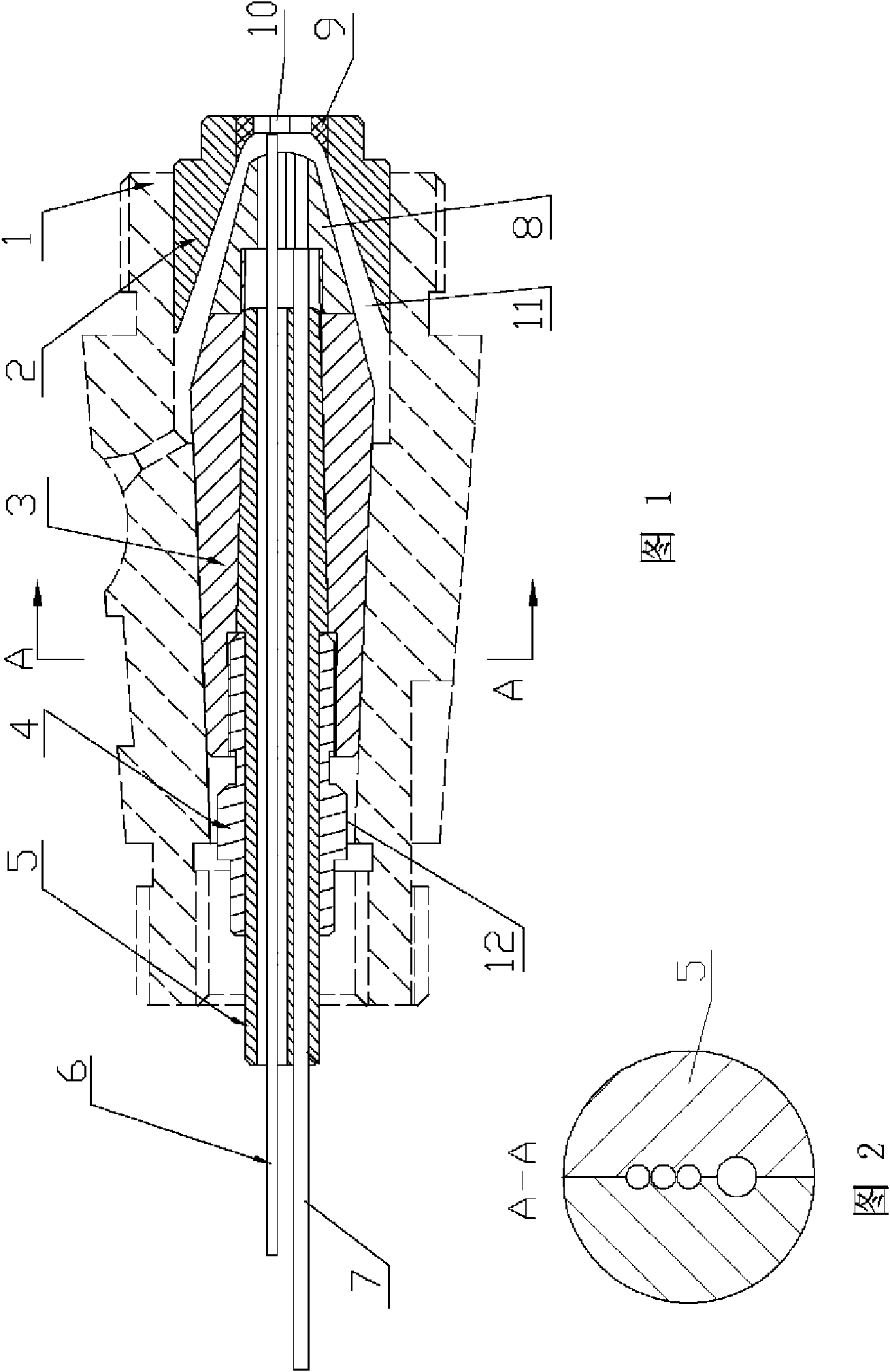

[0016] figure 1 , figure 2 The optical fiber cabling mold shown includes a mold sleeve and a mold core. The front end of the mold core is tapered, and the front end of the mold core cooperates with the mold sleeve with a tapered hole to form a tapered flow channel 11 . The mold cover 2 is composed of the main body of the mold cover and the sleeve body 9 coaxially embedded in the central through hole of the front end of the main body of the mold cover. The parts that are easy to block and easy to wear are set as independent detachable structures, which is convenient for maintenance and reduces maintenance costs.

[0017] The mold core 3 is composed of a core head 8 and a core body. The core body and the core head 8 are screwed into one body, so that the mold core forms a detachable split connection structure. The center of the mold core 3 has an axial taper hole, the front end of the axial taper hole runs through the front end of the mold core, and the tail end of the axial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com