Vane type vacuum pump

一种真空泵、叶片式的技术,应用在旋转活塞式泵、泵、泵元件等方向,能够解决单向阀破损、压力变高、叶片破损等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

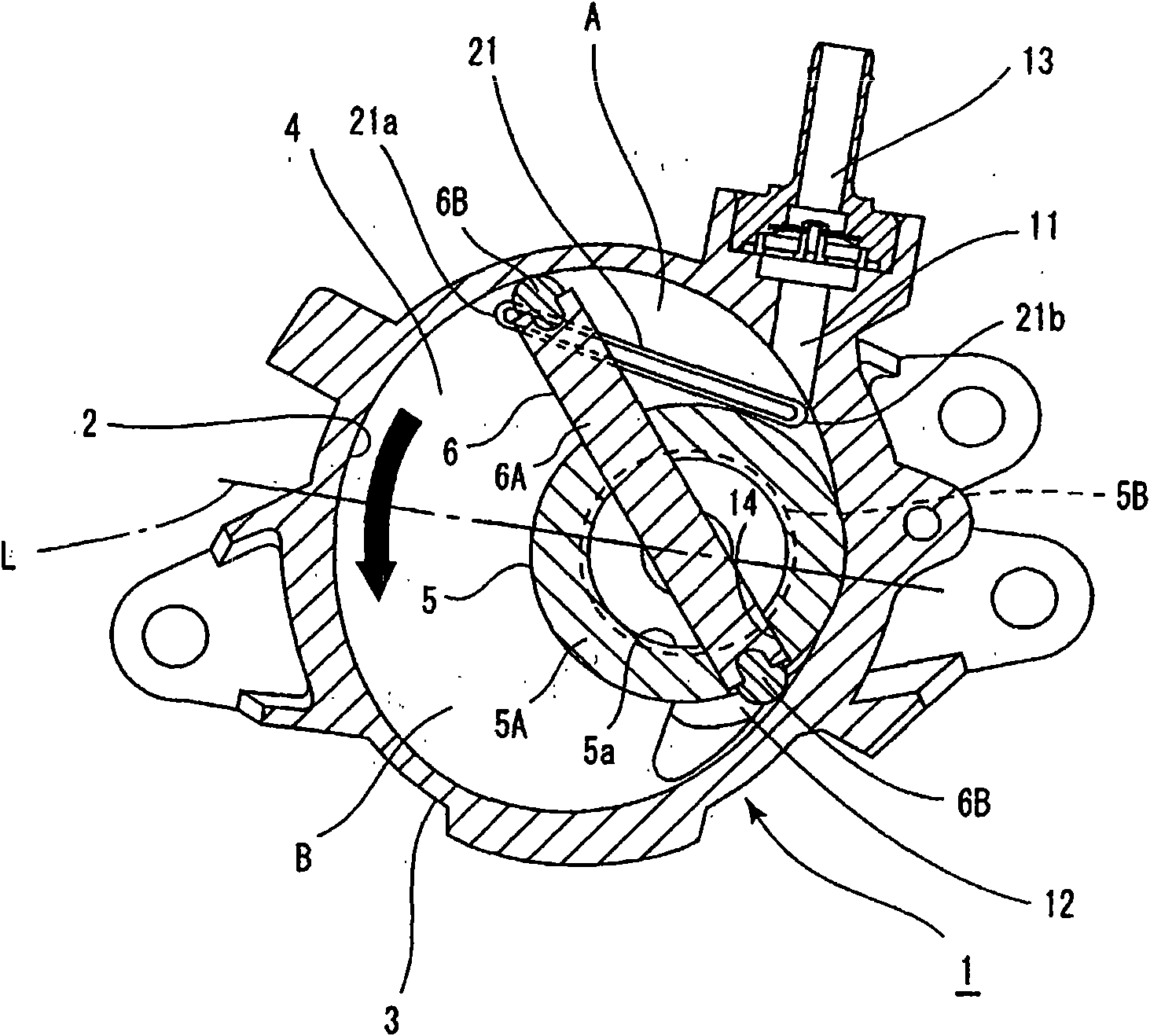

[0006] The invention is illustrated below by way of illustrative examples. exist figure 1 Among them, the vane vacuum pump 1 is fixed on the side of the engine of the motor vehicle not shown in the figure, and the booster device of the brake device not shown in the figure generates negative pressure.

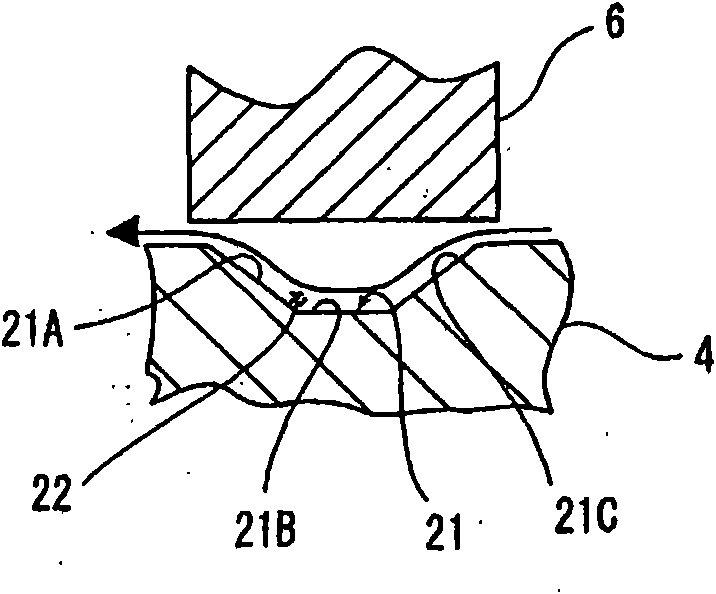

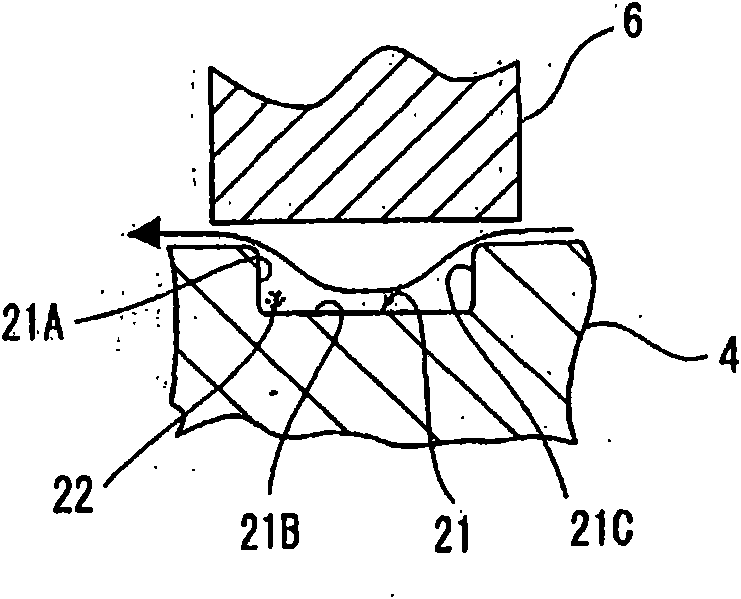

The vane vacuum pump 1 has a housing 3, a side plate 4 (only one side plate is shown in the figure), a rotor 5, and a vane 6; the housing 3 forms a substantially circular pump chamber 2; the side plate 4 seals the Both end surfaces of the casing 3; the rotor 5 is rotated by the driving force of the engine at a position eccentric with respect to the center of the pump chamber 2; the blade 6 is rotated by the above-mentioned rotor 5, and often divides the pump chamber 2 into a plurality of spaces; the above-mentioned rotor 5 and the blade 6 are rotationally driven in the counterclockwise direction indicated by the arrow in a normal state.

[0007] In the above-mentioned case 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com